Arc-cutting mould for spiral spring seat of automobile rear axle and arc-cutting process for arc-cutting mould

A technology of coil springs and automobile rear axles, applied in the field of mechanical processing, can solve problems such as high processing costs, insufficient strength, and difficult production, and achieve the effects of improving production efficiency, ensuring consistency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

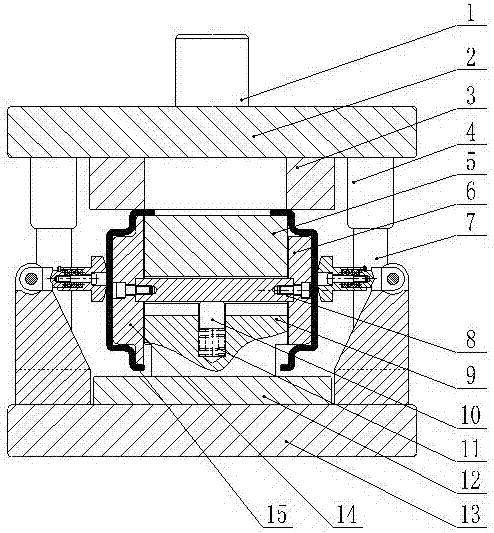

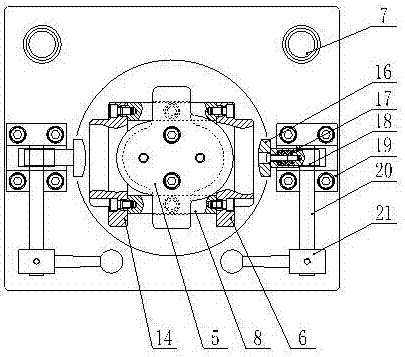

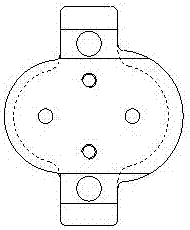

[0041] Such as Figure 1 to Figure 13 As shown, a mold for cutting an arc of a helical spring seat of an automobile rear axle includes a mold handle 1, an upper template 2, a die 3, a guide sleeve 4, a punch 5, a large arc positioning block 6, and a guide post 7 , connecting rod 8, punch backing plate 9, top block 10, top piece spring 11, bottom backing plate 12, lower template 13, small arc positioning block 14, chuck 16, compression spring 17, pressure rod 18, pressure Rod bearing 19, rotating shaft 20, handle 21.

[0042] The upper mold is equipped with a die 3 through the upper template 2, and the die 3 is fixed under the upper template 2 through pins and fastening bolts; Die backing plate 9, punch 5 are fixed on the punch backing plate 9 by bolts and pins, grooves are horizontally provided in the middle of punch backing plate 9, and a connecting rod 8 is horizontally slidably connected in the groove, and a connecting rod 8 is arranged below the connecting rod 8. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com