Multi-fulcrum suspension crane suspension assembly mold and its application method

A technology for suspending cranes and assembling molds. It is applied in the directions of load hanging components, transportation and packaging. It can solve problems such as excessive wear of rails, inability to adjust rails, and inability to control geometric dimensions. It can reduce operating strength, improve assembly efficiency, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

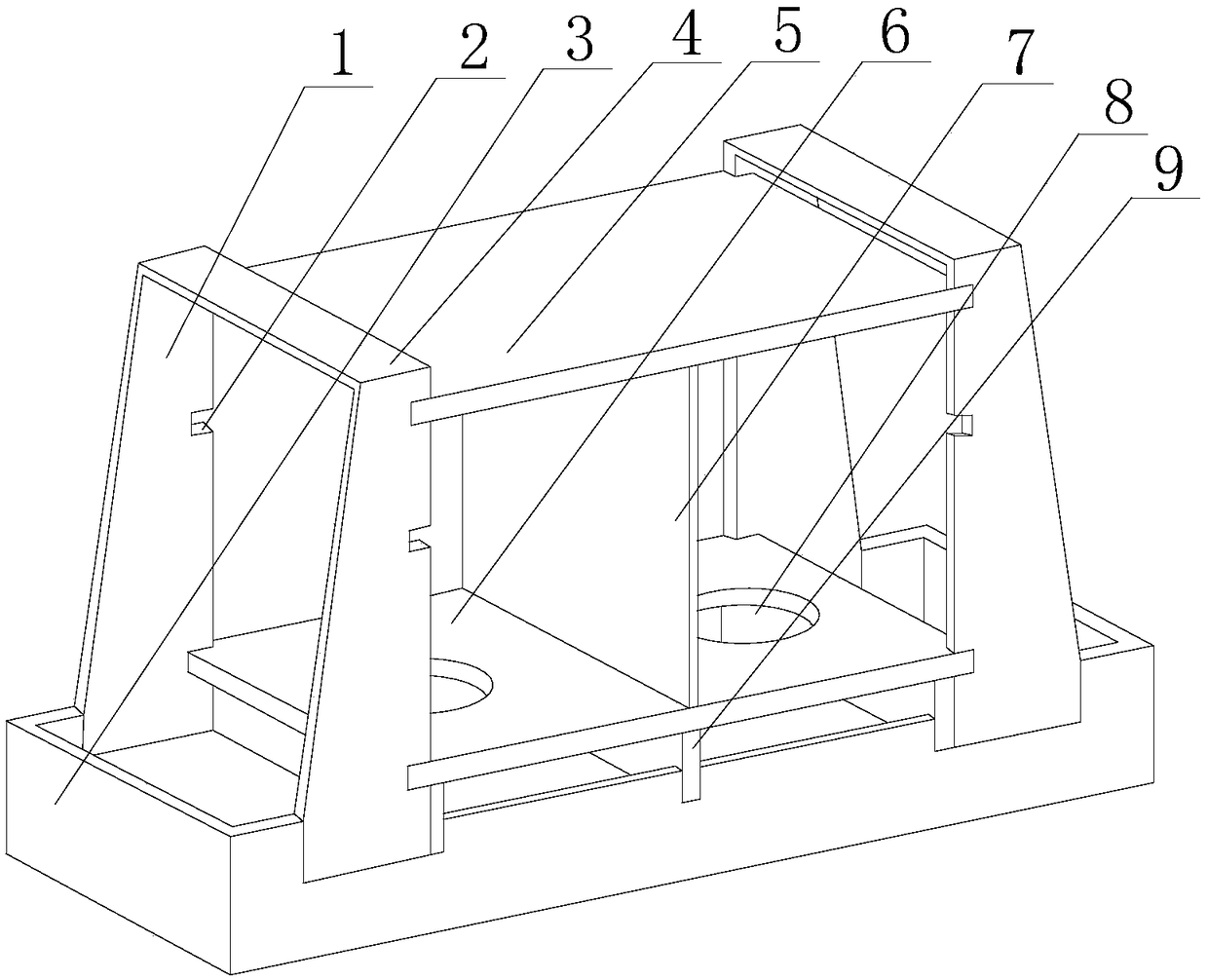

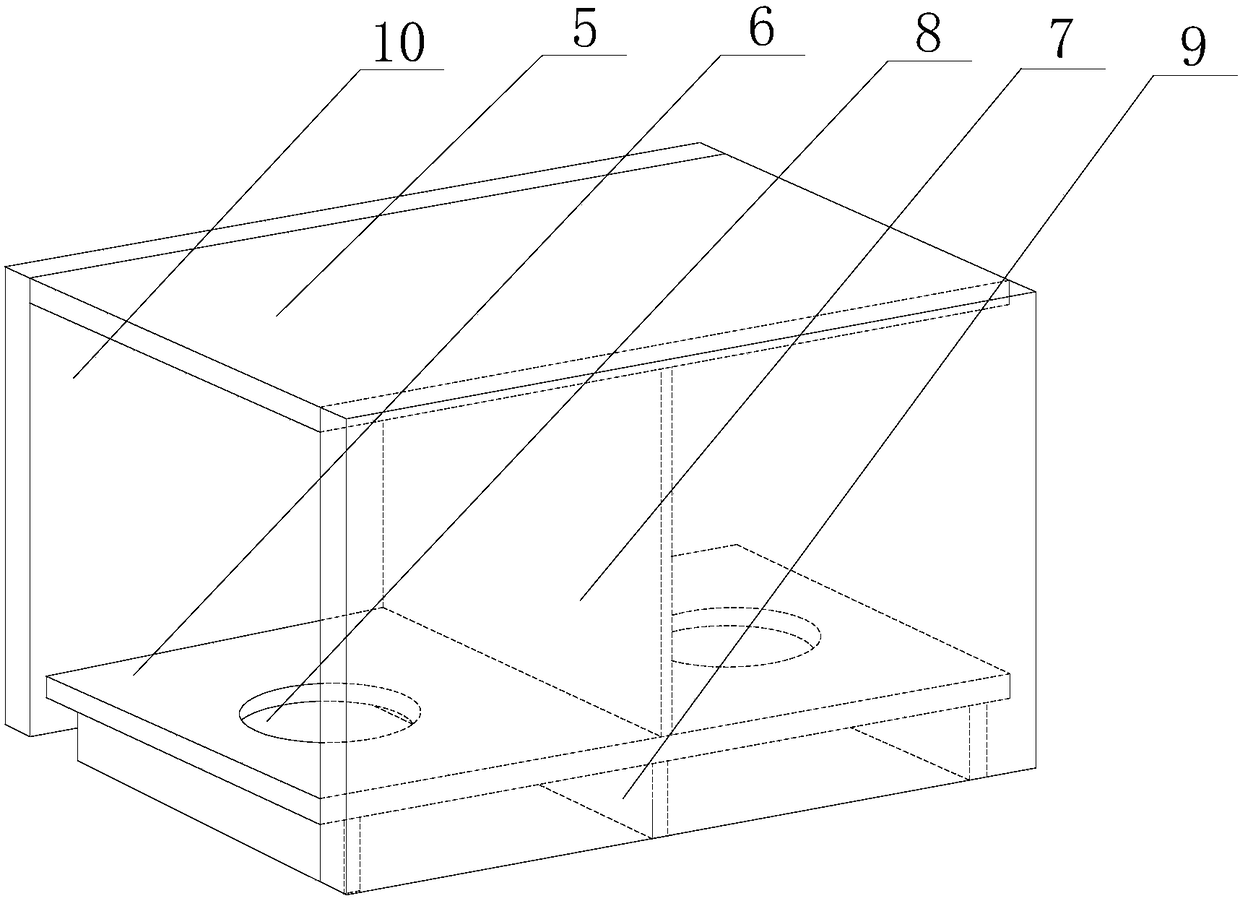

[0029] Such as Figure 1~2 As shown, the present embodiment includes a card holder 3 in the shape of a square frame, two positioning slots are respectively opened on the two opposite frames of the card bracket 3, and a clamp placed in the positioning slot is also included. The fixture is a rectangular frame formed by splicing two support plates 4 and two side plates 1, and a plurality of bayonet slots 2 are provided on the inner side wall of each side plate 1, and on the frame of the card holder 3 There are a plurality of limiting slots, and the plurality of limiting slots are located between the two positioning slots. In the large-span workshop, in the manual welding method used in the installation of the suspension parts of the multi-point suspension crane, the assembly of the various part plates in the suspension parts is prone to large deviations, so that the track cannot be adjusted and the crane Inability to walk normally or excessive wear on the track. In this regard, ...

Embodiment 2

[0035] Such as Figure 1~2 Shown, present embodiment comprises the following steps on the basis of embodiment 1:

[0036] A. Place two fixtures on the positioning slot of the card holder 3;

[0037] B, a plurality of stiffening plates 9 are placed in the limit groove;

[0038] C. Insert the bottom plate 6 and the top plate 5 horizontally into the two corresponding bayonet sockets 2 respectively, and adjust the bottom plate 6 and the top plate 5 so that the midlines of the two are aligned, and align the upper ends of the multiple stiffening plates 9 with the bottom surface of the bottom plate 6 Welding fixed;

[0039] D. Insert reinforcement between the bottom plate 6 and the top plate 5 along the long side direction of the stiffening plate 9, so that the midline of the reinforcing plate 7 coincides with the bottom plate 6, and weld the bottom plate 6, the top plate 5 and the reinforcing plate 7 into a whole;

[0040] E. Two sealing plates 10 are respectively welded on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com