Converter with DC link

An intermediate circuit, DC voltage technology, applied in the field of converters, can solve problems such as difficulty in realizing a space-saving and compact structure, and achieve the effects of low switching loss, reduced wire length, and low leakage inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

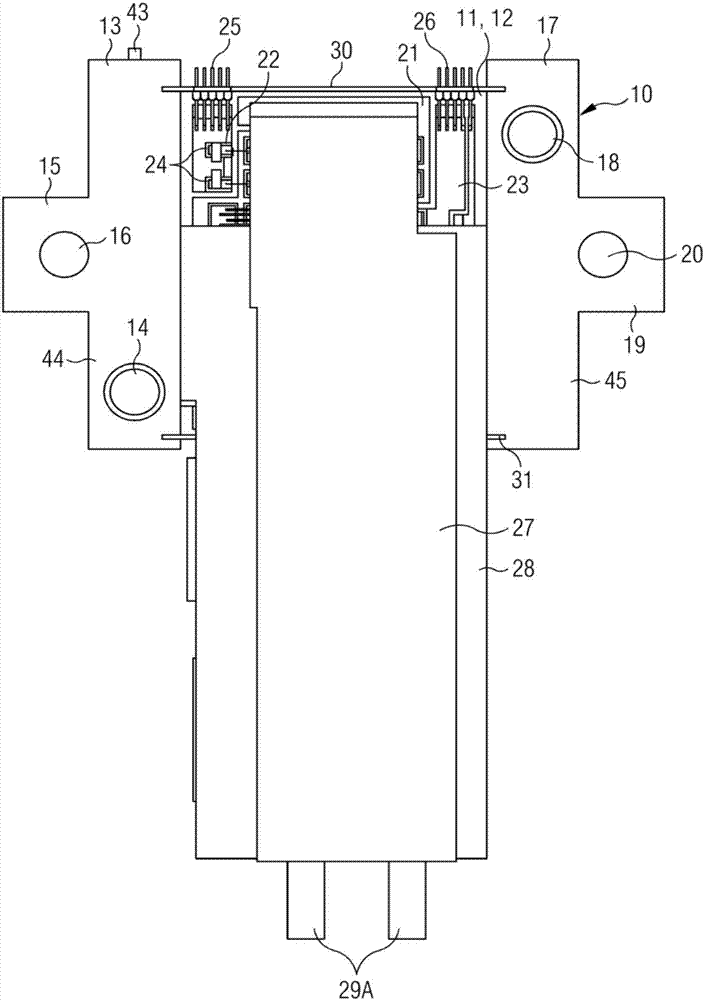

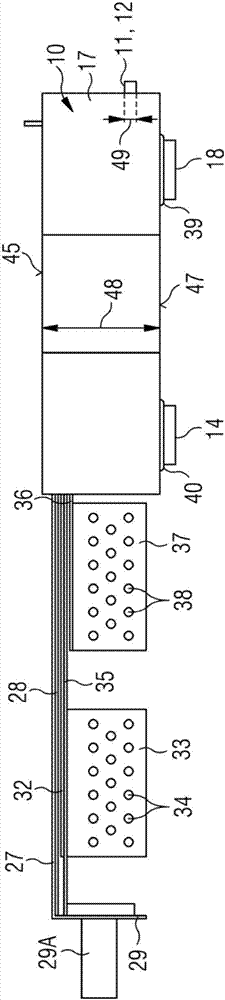

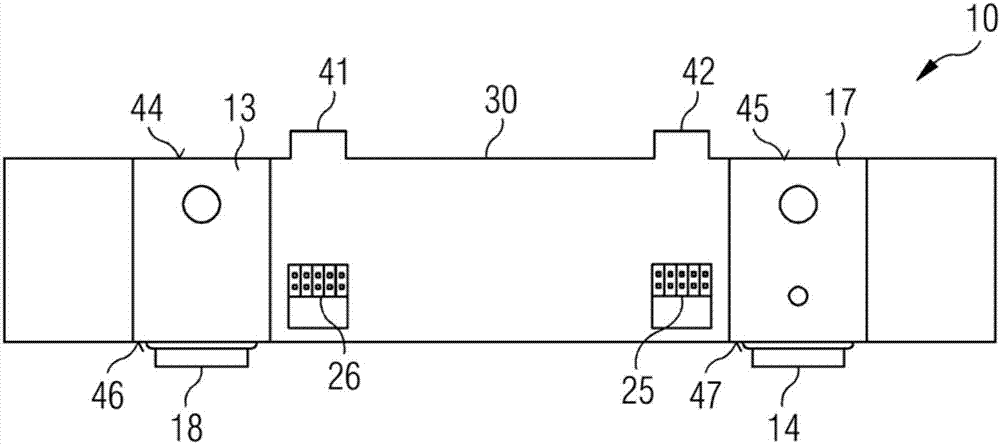

[0042] Figure 1 to Figure 6 An embodiment of the module 10 according to the present invention is shown. The modules can be used in a converter with a DC voltage intermediate circuit according to the present invention in a way that they can be stacked individually or on top of each other to form a module complex. The converter is used to convert the input voltage into an alternating voltage with a predetermined amplitude and frequency to control a single-phase or multi-phase load not shown in the figure.

[0043] In the drawings, the same elements are marked with the same reference signs.

[0044] figure 1 A top view of the module 10 is shown. The module 10 includes a ceramic heat sink 11 with a receiving surface 12. in figure 1 In the view, the receiving surface 12 extends parallel to the plane of the drawing. Conductive areas 21, 22, 23 are arranged on the receiving surface 12, and a large number of electronic components 24 are arranged on the conductive areas. The electronic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com