Vehicle-mounted navigation system mounting structure and engineering machine

A technology for vehicle navigation and installation structure, which is applied to radio wave measurement systems, antenna supports/installation devices, satellite radio beacon positioning systems, etc. Accuracy and other issues, to achieve the effect of reducing adverse effects, small vibration amplitude, and reducing wiring length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

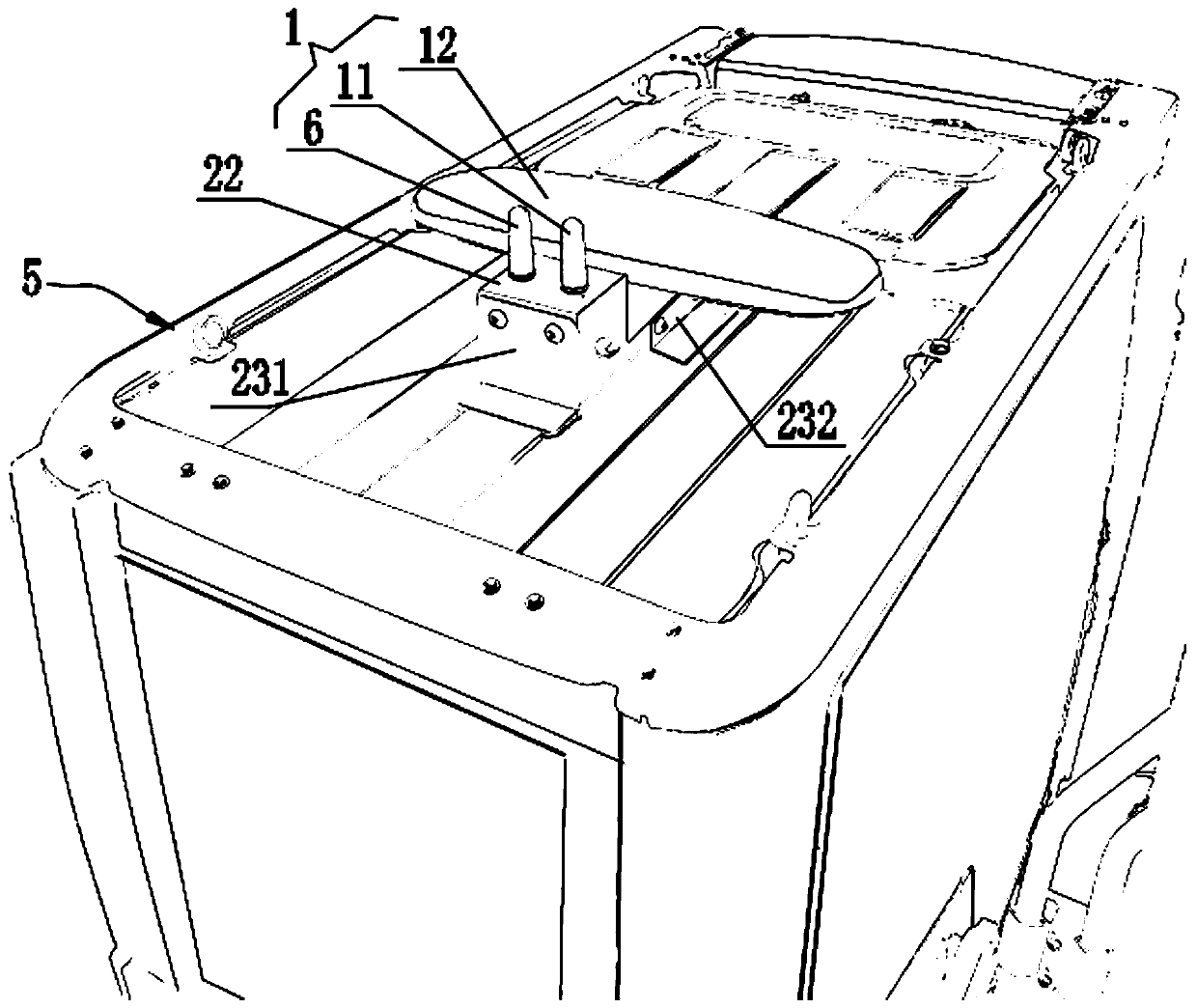

[0039] see Figure 1 to Figure 3 , a preferred embodiment of the present invention discloses an installation structure of a vehicle navigation system, which is installed on the roof of a construction machine, and the construction machine refers to an excavator, a rock drilling jumbo, a rotary excavator or other Construction machinery equipped with on-board navigation systems.

[0040] The installation structure of the vehicle navigation system includes a vehicle navigation system 1 and a mounting base 2 fixedly connected to the roof, and the vehicle navigation system 1 is installed on the mounting base 2 .

[0041]The vehicle navigation system 1 includes a radio station 11 and a GNNS receiver 12. The GNNS receiver 12 is equipped with a directional antenna and a positioning antenna, and the directional antenna is a preset distance away from the positioning antenna. Specifically, the GNNS receiver 12 has a housing, and the directional antenna and the positioning antenna are fix...

Embodiment 2

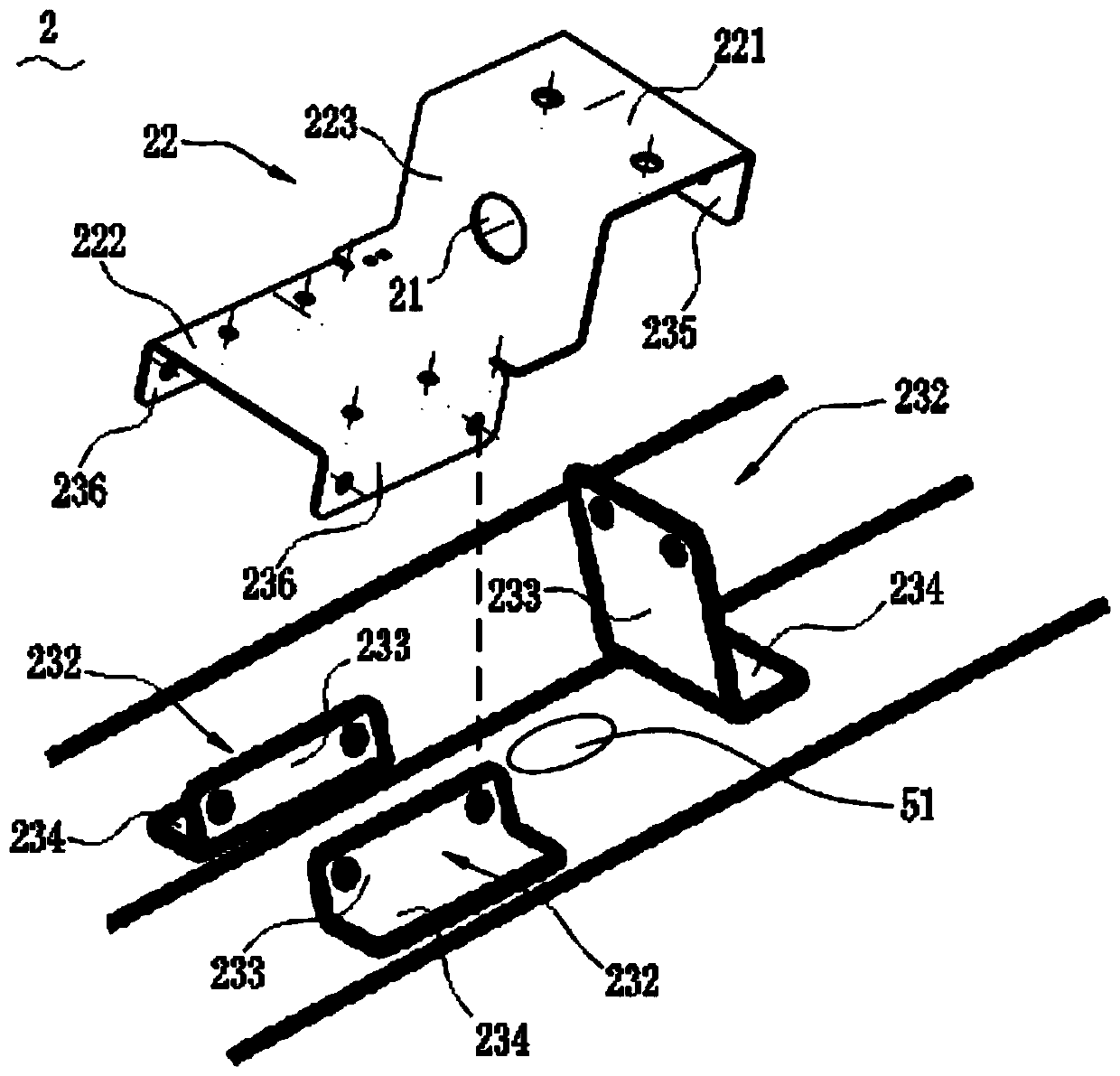

[0050] see Figure 1 to Figure 3 , another embodiment of the present invention discloses an installation structure of a vehicle navigation system, which includes a vehicle navigation system 1 and a mount 2 fixedly connected to the roof of the vehicle. The structure and positional relationship of this embodiment are basically consistent with Embodiment 1, the differences are:

[0051] The mounting seat 2 includes a seat plate 22 and three supporting legs, the three supporting legs are fixed on the roof, and the three supporting legs are fixedly connected to the bottom of the seat plate 22 .

[0052] Further, the seat plate 22 is stepped, including an upper mounting plate 221, a lower mounting plate 222 and a connecting plate 223 connecting the upper mounting plate 221 and the lower mounting plate 222, the upper mounting plate 221 and the lower mounting plate 222 are The lower mounting plate 222 is arranged horizontally, and the upper mounting plate 221 is higher than the level...

Embodiment 3

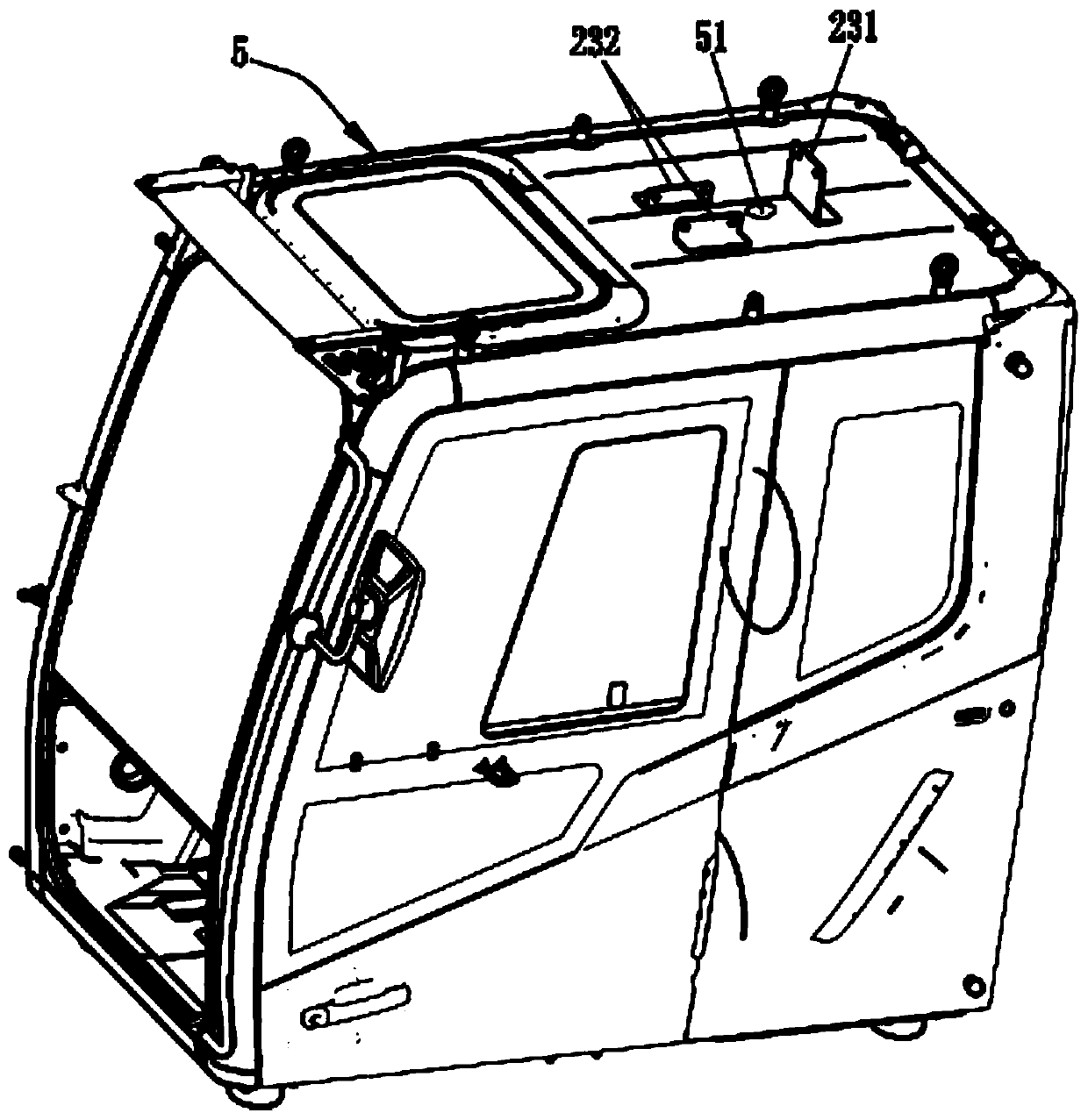

[0062] see Figure 1 to Figure 3 , the third embodiment of the present invention discloses a construction machine, which includes a cab 5 and the installation structure of the vehicle navigation system of the above-mentioned embodiment 1 or embodiment 2, the installation structure of the vehicle navigation system is located in the cab 5 The top of the cab 5 is provided with a through hole 51 for wiring, the cab 5 is equipped with an electric control cabinet (not shown), and the wiring harness of the vehicle navigation system 1 passes through the through hole 21 and The through hole 51 is connected with the electric control cabinet.

[0063] Compared with other installation positions, the vibration amplitude of the cab 5 of construction machinery is relatively small. In this embodiment, the vehicle navigation system 1 is installed on the top of the cab 5, which can minimize the vibration of the vehicle body to the vehicle navigation system 1. In addition, the vehicle navigatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com