Inclined wedge type pre-extending drawing mould

A drawing die and wedge technology, applied in the field of drawing dies, can solve the problems of not too shallow drawing depth, increased driving noise, and vehicle agitation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

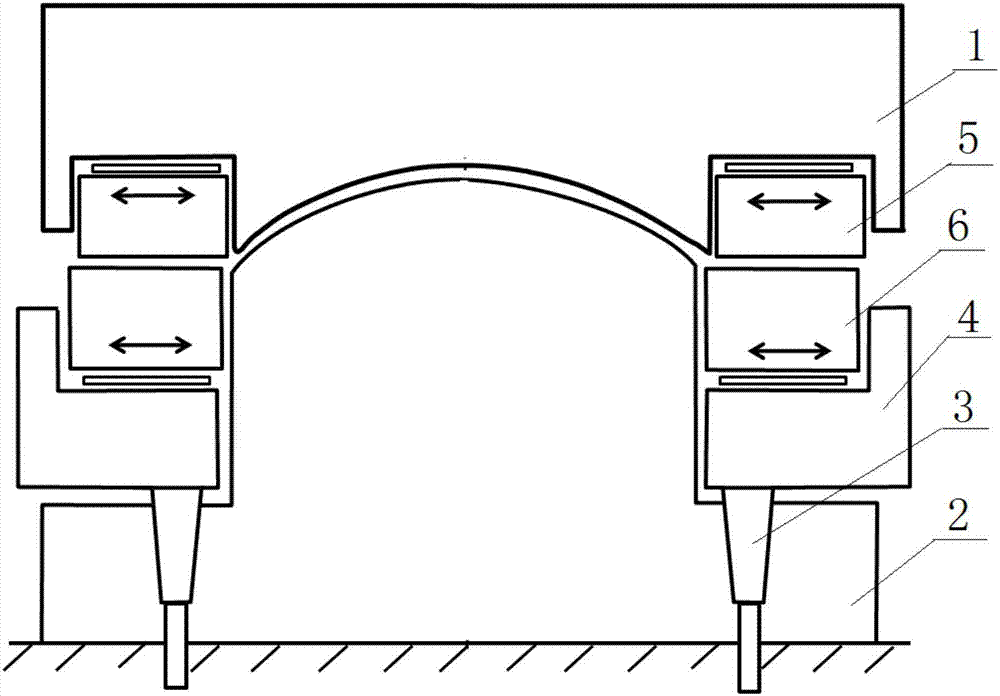

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

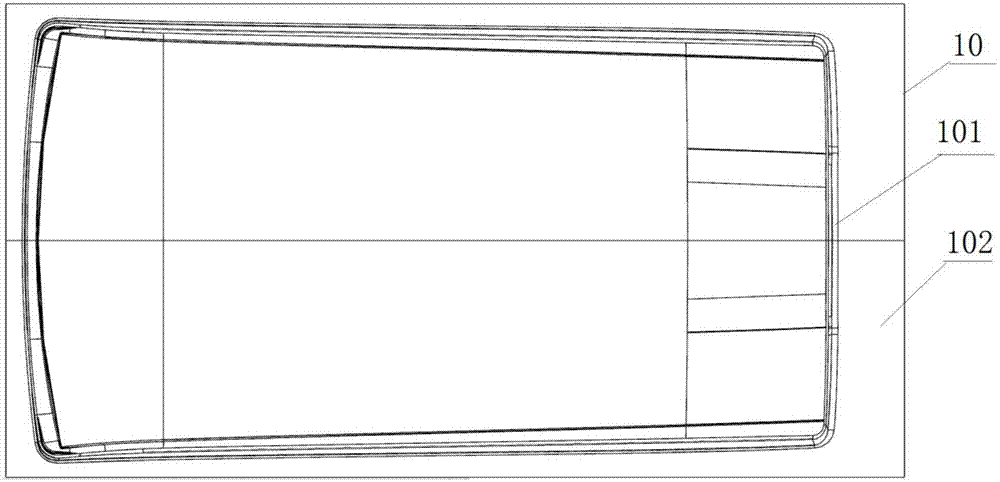

[0028] The drawing die of the present invention is mainly used in the drawing process of shallow-drawing thin material thickness (material thickness less than 1mm) of the body outer cover. . Among the outer covering parts of the car body: parts such as the top cover and the outer panel of the hood are typical shallow drawn sheets, and the shape of the top cover is symmetrical and the closest to a rectangle. Usually, some areas of the top cover are prone to insufficient plastic deformation during drawing, so that Insufficient sheet rigidity. The present invention is illustrated by taking the top cover single-action drawing die as an example.

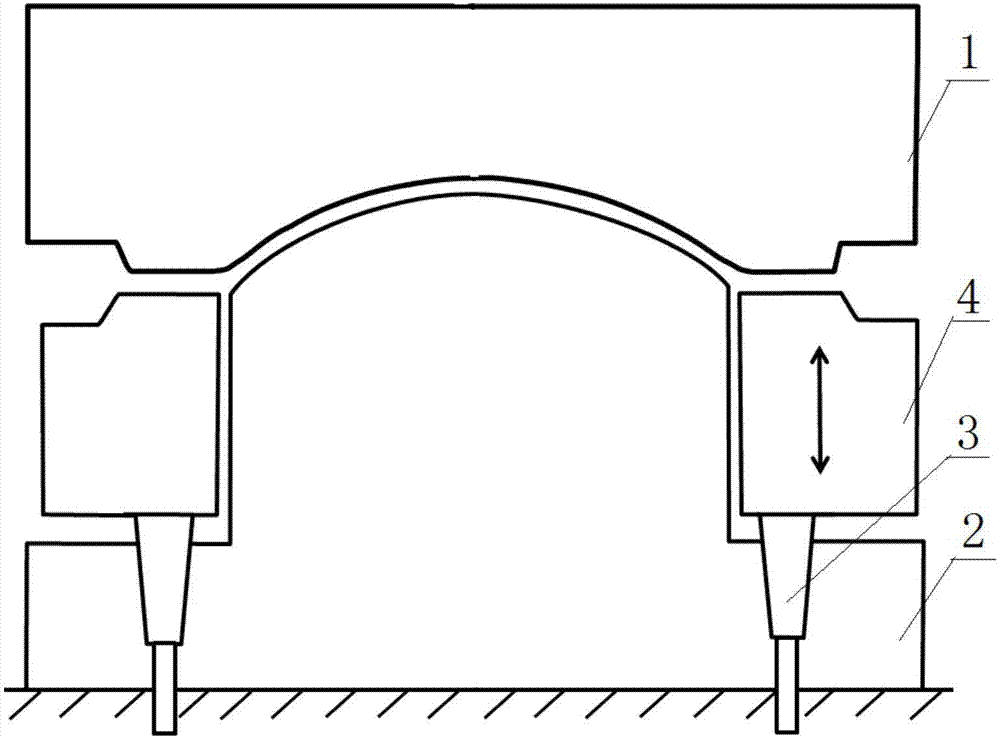

[0029] Such as figure 1 As shown, a traditional single-action drawing die includes a die 1 (upper die), a punch 2 (lower die), a support bar leg 3 (integrated or split with the binder ring) and a binder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com