Winding reel for spinning

A technology of reel and pressing plate, which is applied in the field of textile equipment, can solve problems such as low work efficiency, troublesome use, and thread knotting, and achieve the effects of easy on-line, convenient use, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

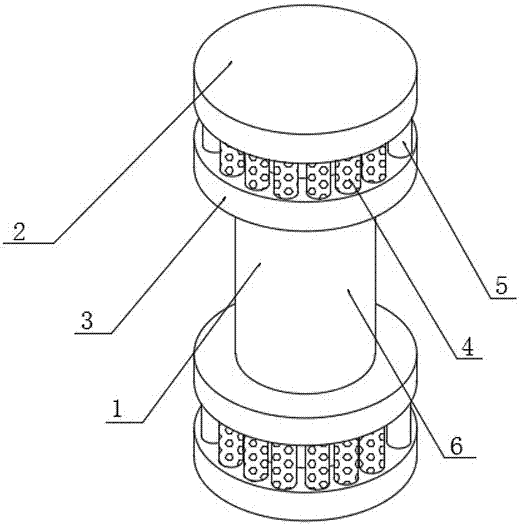

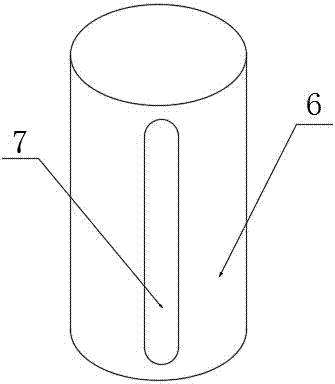

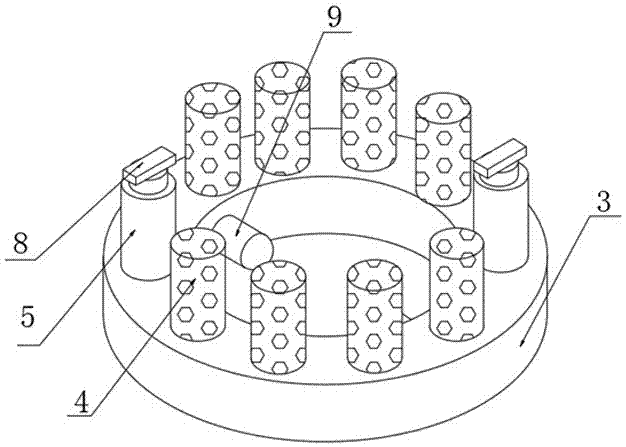

[0022] Such as Figure 1-5 As shown, the present invention provides a spinning reel for weaving, which includes a device body 1, a base plate 2 is provided at both ends of the device body 1, a pressing plate 3 is provided at the bottom of the base plate 2, and there are respectively provided between the base plate 2 and the pressing plate 3. Spring 4 and connecting rod 5, the bottom of pressing plate 3 is provided with reel 6, and the surface of reel 6 is provided with chute 7, and the top of connecting rod 5 is provided with fixed dead bolt 8, and the inner wall of pressing plate 3 is provided with slideway. Block 9, the surface of base plate 2 is provided with connecting lock body 10, and the surface of connecting lock body 10 is provided with fixed block 11, and the bottom of fixed block 11 is provided with rotating block 12, and the inside of connecting lock body 10 is provided with lock groove 13.

[0023] The bottom plate 2, the pressing plate 3 and the reel 6 are all ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com