Automatic rail surface derusting machine

A rust remover and rail surface technology, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of incompatibility with special railway lines, ineffective signal equipment, affecting the conductivity of rails, etc., and achieve rust removal on the rail surface. The effect of automation, preventing signal equipment failure, saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

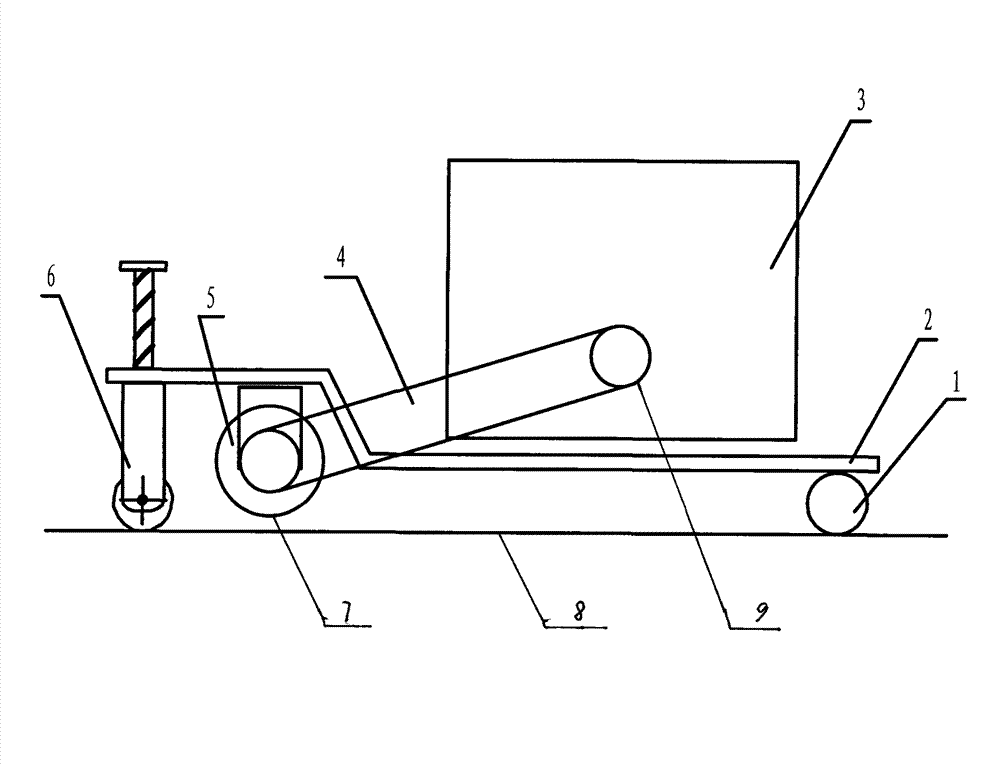

[0015] As shown in the attached figure, the automatic rail surface derusting machine adopts a fish-belly steel frame structure as a whole, which is composed of three parts: the front part, the middle part and the rear part. The front part is composed of the front guide wheel 1 and the balance wheel. The rear part is made up of rear guide wheel 7 and lifting frame 6, and the top of front guiding wheel 1 and the top surface of lifting frame 6 are arranged to connect a planar step-shaped supporting frame plate 2, on the lifting frame 6 side, the support frame plate 2 A steel wire rolling wheel 5 is fixedly arranged on the rear bottom surface, and the steel wire rolling wheel 5 is connected with the transmission wheel 9 of the power unit 3 by a belt drive 4 . Power unit 3 is arranged on the middle part, is made up of engine, belt, power transmission shaft, bearing seat, spacer and transmission wheel.

Embodiment 2

[0017] When the automatic rail surface derusting machine is on-line, the equipment is placed on one side of the steel rail 8, and the balance wheel is placed on the other side to ensure that the equipment is stable, the power source is started, and the output is smooth and stable through the transmission device. The specific speed and specific torque drive the steel wire The wheel rotates at high speed, adjust the height of the lifting frame to provide a certain pre-tightening force, so as to achieve the contact between the wire wheel and the rail surface, and derust the surface. Through experiments, the derusting effect fully meets the design requirements, restores the electrical conductivity of the rail surface, makes the current flow back, ensures the normal and reliable operation of the signal equipment, and ensures the safety of railway traffic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com