Data display and storage method for steel rail flaw detection operation

A technology for data display and operation, which is applied in the processing of detection response signals, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. The effect of improving the effect of flaw detection inspection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For the sake of reference and clarity, the technical terms, abbreviations or abbreviations used below are recorded as follows:

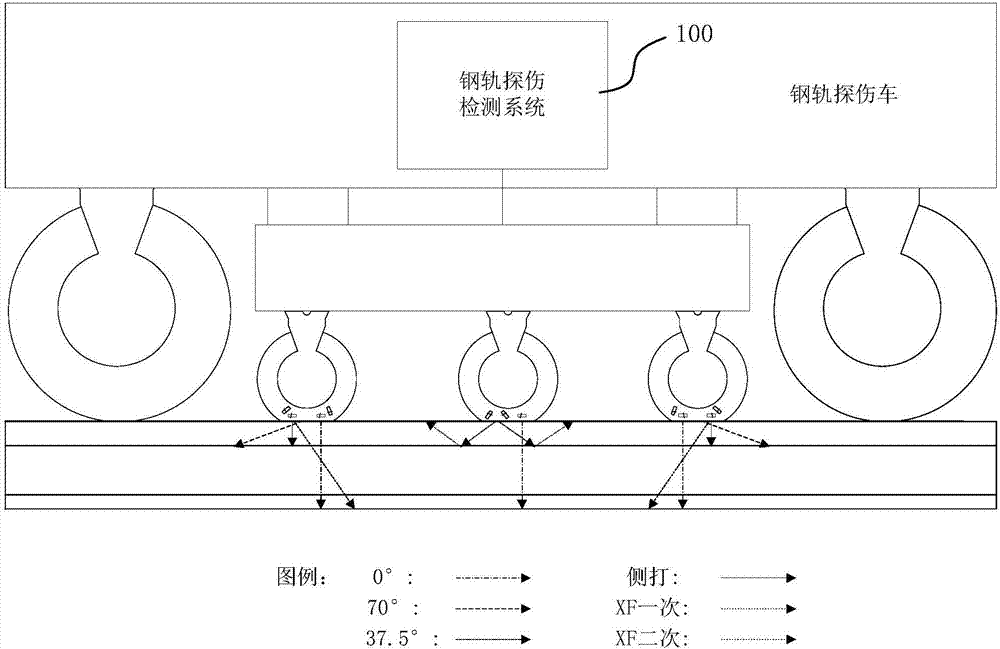

[0031] Probing wheel: a wheel structure, the center frame of the shaft is equipped with several ultrasonic chips with different detection angles, and the outer film of the tire is filled with coupling fluid. When the locomotive is running, the probing wheel rolls along the rail, and the moving direction of the detection chip is parallel to the rail ;

[0032] A-type display: It is a display method for displaying analog ultrasonic signals through an oscilloscope;

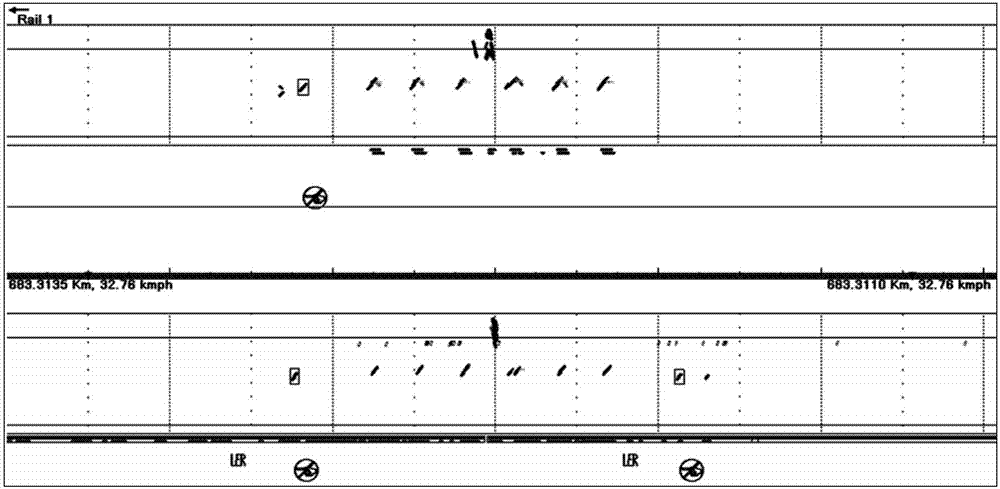

[0033] B-type display: It is a display method that visually displays the information of ultrasonic reflection points inside the rail through images;

[0034] FIFO: First Input First Output, the abbreviation of first-in-first-out memory;

[0035] A / D acquisition: Analog / Digital, short for analog / digital acquisition;

[0036] FPGA: Field Programmable Gate Array, short for Field Prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com