Water recovery device for plant wall

A water recovery and plant wall technology, applied in the direction of automatic watering devices, botanical equipment and methods, applications, etc., can solve the problems of waste of water resources, poor ventilation, low light intensity, etc., to avoid equipment damage and simple structure , the effect of increasing the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

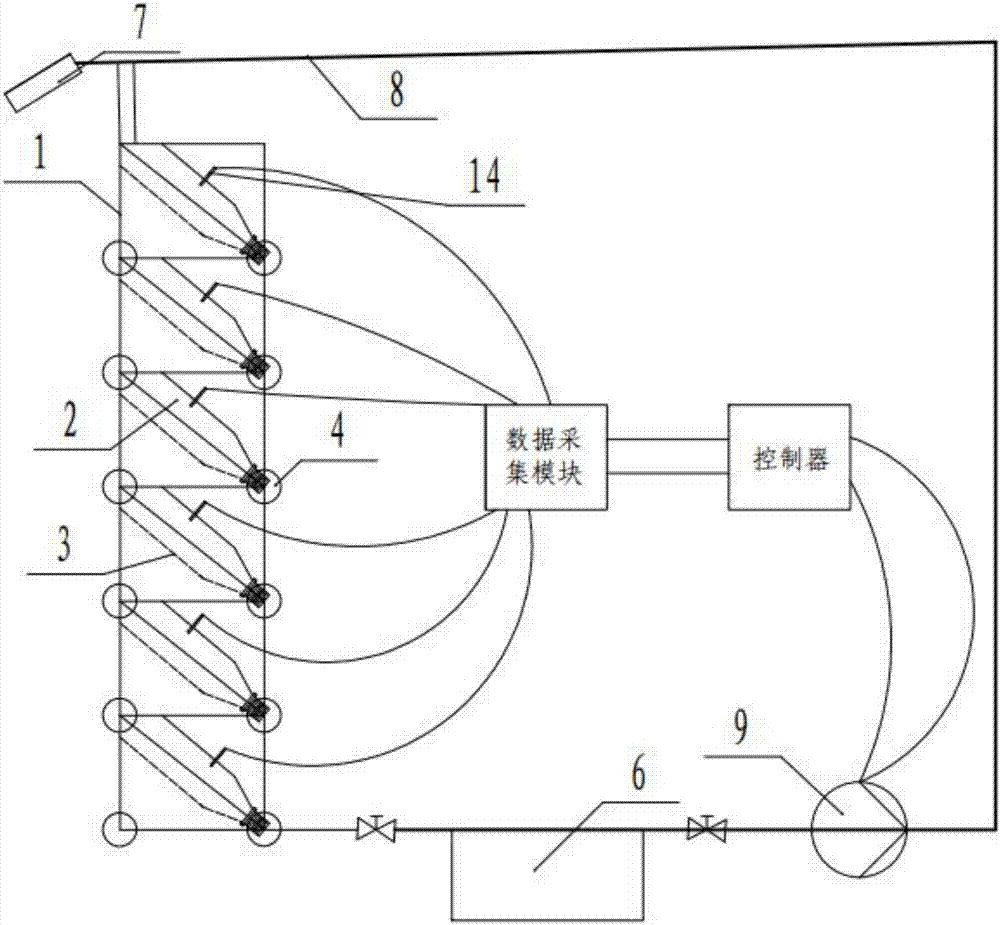

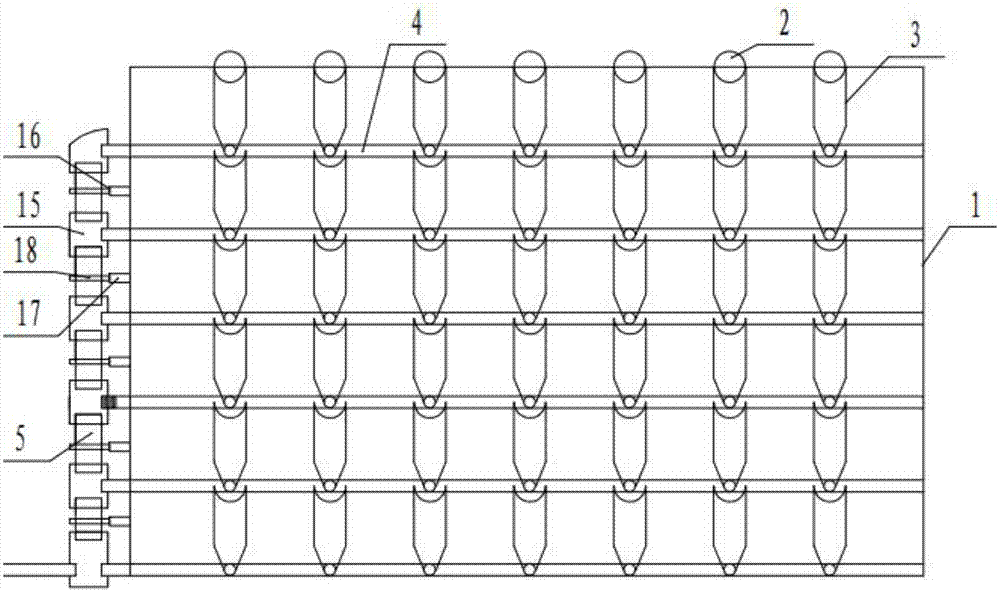

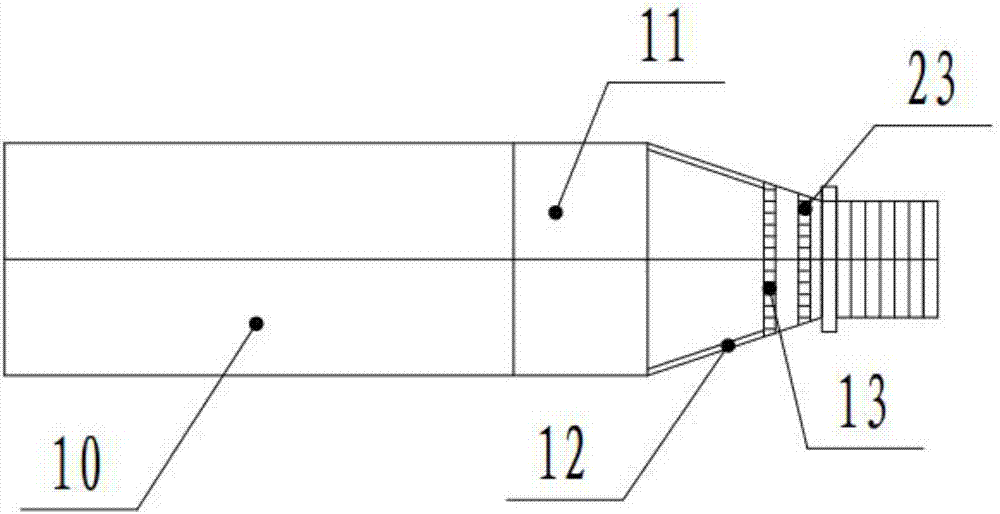

[0019] Embodiment 1: as Figure 1-Figure 4 As shown, a water recovery device for a plant wall, which includes a return water branch pipe 4 and a return water main pipe 5, the return water branch pipe 4 is fixedly connected to the rear side of the plastic-steel exterior wall 1, and the return water branch pipe 4 is respectively connected to each row The bottle mouth of each mineral water bottle 2 lower ends, one end of the backwater branch pipe 4 is sealed, and the other end is connected on the backwater main pipeline 5, and the backwater main pipeline 5 is connected to the sump 6.

[0020] Preferably, a grate 19 is provided at the water inlet and outlet of the above-mentioned sump 6 .

[0021] Preferably, the water collecting tank 6 is provided with a drain pipe 20 near the top side wall.

[0022] Preferably, the above-mentioned sump 6 is provided with a liquid level sensor 22 .

[0023] Preferably, the above-mentioned return water branch pipe 4 is connected to the return wa...

Embodiment 2

[0026] Embodiment 2: as Figure 1-Figure 4 As shown, the above-mentioned recovery device is used for a plant wall, and the plant wall includes a plastic steel outer wall 1 and a mineral water bottle 2. The plastic steel outer wall 1 is provided with multiple rows of placement grooves 3 inclined downward from the outside to the inside, and each row of each place A mineral water bottle 2 is placed obliquely in the groove 3. The mouth of the mineral water bottle 2 faces inwardly and downwardly, and its upper end opening faces outwardly upwardly. The inside of the bottle is used for planting plants. Placed in the tank, it is convenient to load, unload and replace plastic bottles. Mineral water bottles are recycled and used, and the production cost is greatly reduced. Simple, easy to disassemble and operate.

[0027] Preferably, a shower head 7 is arranged on the outer side of the plastic-steel exterior wall 1. The shower head 7 is mechanically rotating. The shower head 7 is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap