Side-flanging die structure

A technology of side flanging and mold mechanism, which is applied in the field of stamping molds for auto parts, can solve problems such as increased procedures, complex mold structure, and complicated process methods, and achieve the effects of increasing work efficiency and simplifying the stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

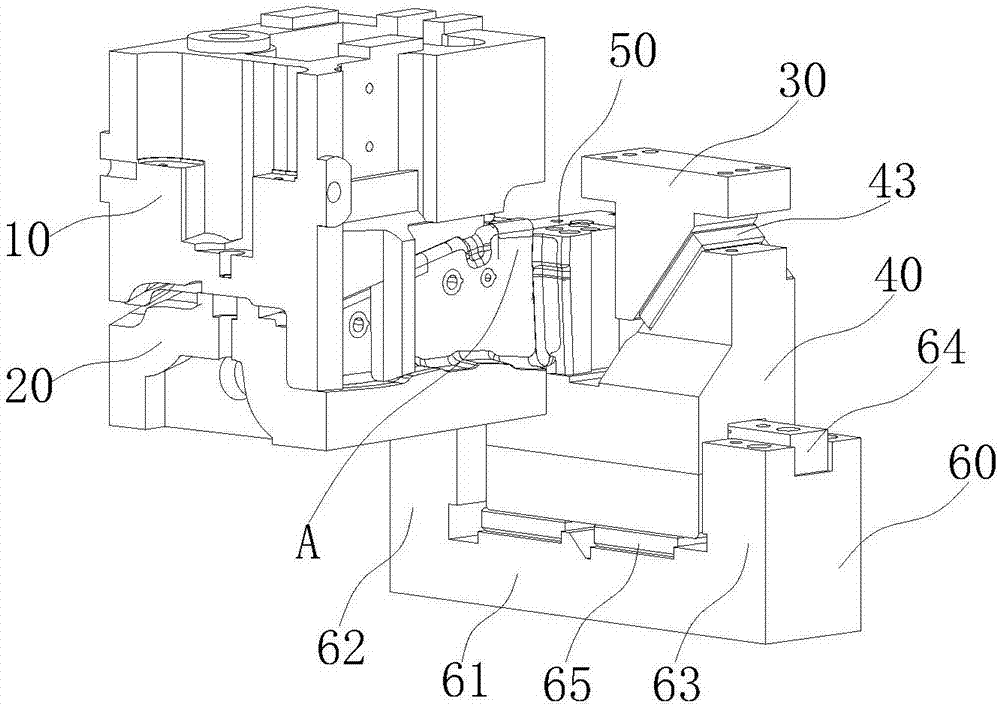

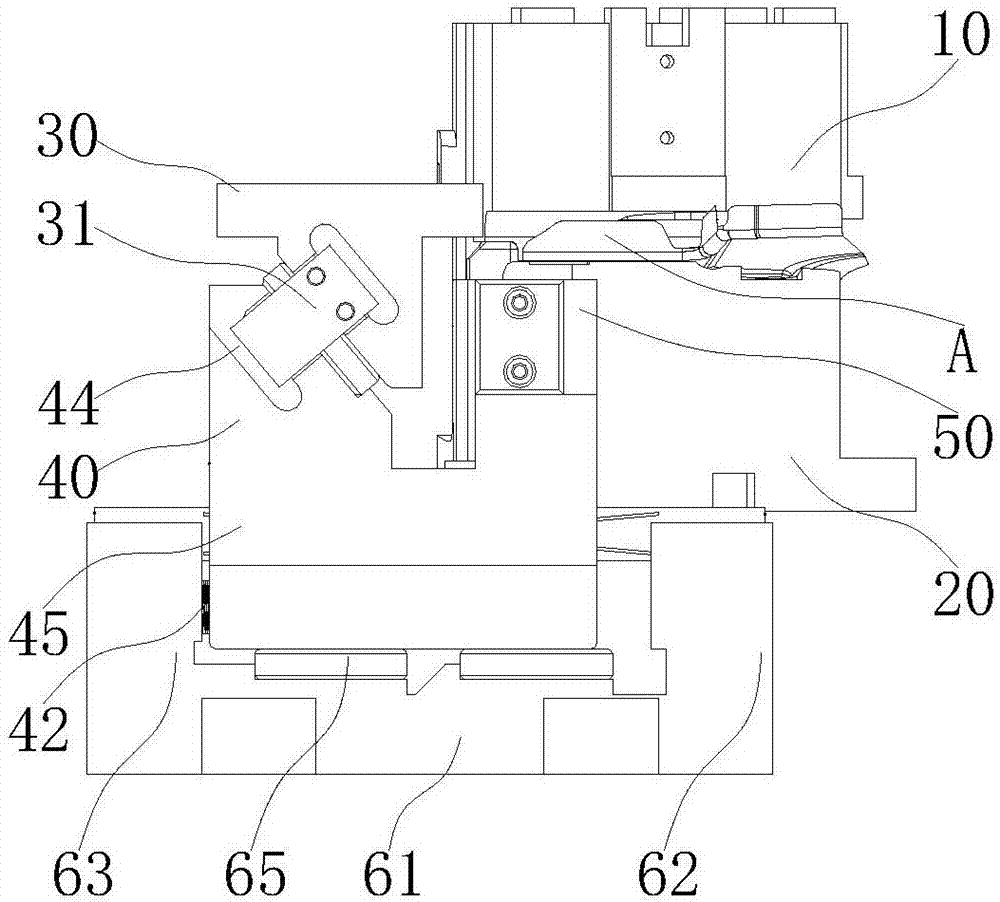

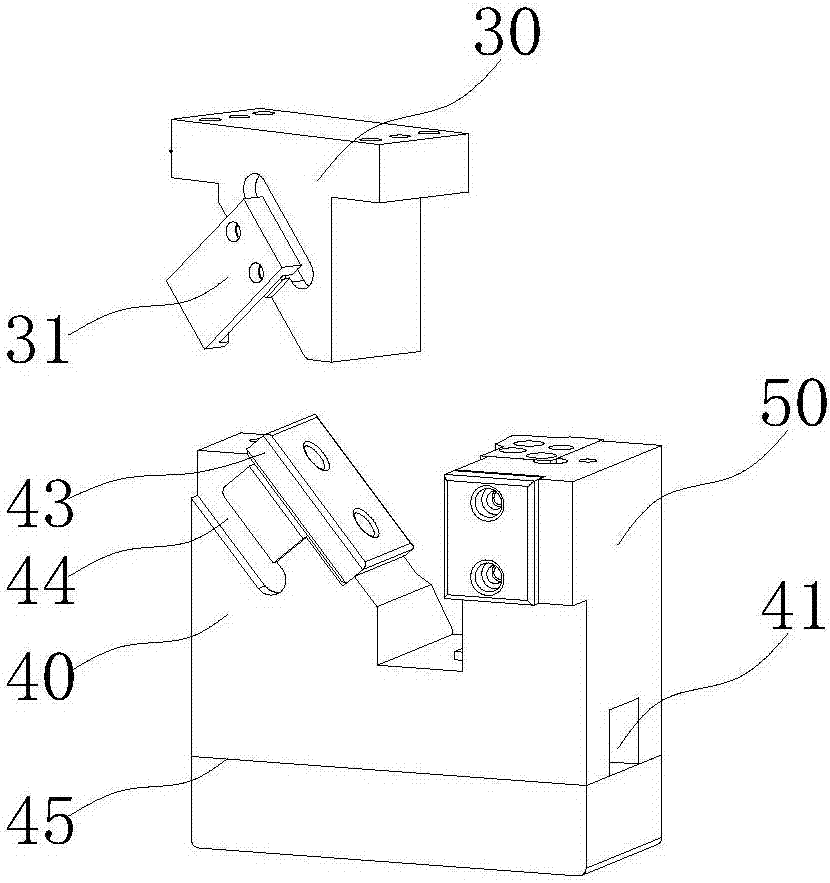

[0010] combined with Figure 1~4 The present invention is further described:

[0011] A side flanging mold mechanism, the pressing core 10 and the fixed lower mold 20 are molded together to shape the workpiece A and maintain a clamping state, and the area to be flanged of the workpiece A protrudes to the pressing core 10 and the fixed lower mold 20. Outside the forming area of the fixed lower mold 20, the drive block 30 is matched with the sliding wedge 40 and arranged opposite to the area to be flanged of the workpiece A. The sliding wedge 40 is connected to the flanging tool 50, and the area to be flanged and The boundary line between the forming surfaces of the workpiece A is located on one side of the flanging tool 50 close to the fixed lower mold 20 and is always on the traveling route of this side, and the pressing driving block 30 collides with the sliding wedge 40 to cause relative slippage and produce The beveling force pushes the sliding wedge 40 to move in a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com