Drill bit with single chip removal groove and double cutting edges and method for avoiding electrochemical migration between board holes

A chip flute, double cutting technology, used in drilling/drilling equipment, components of boring machines/drilling machines, drilling repairs, etc., can solve the problems of electrical performance failure of circuit boards, lack of improvement methods, and insufficient attention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] like Figure 5 As shown, the mechanical drilling of the circuit board will damage the interface between the glass fiber and the resin, resulting in cracks, and the electroplating solution remains in the cracks, providing channels and ions for electrochemical migration.

[0030] The present invention attempts to avoid the electrochemical migration between holes by reducing the damage of the mechanical drilling and the residue of the electroplating liquid.

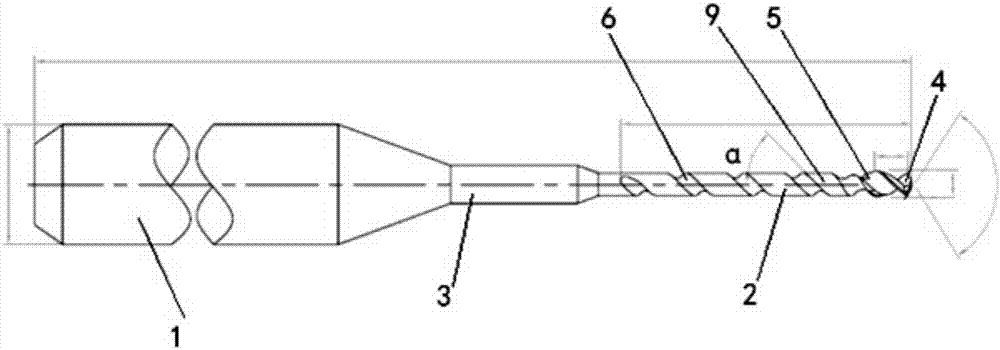

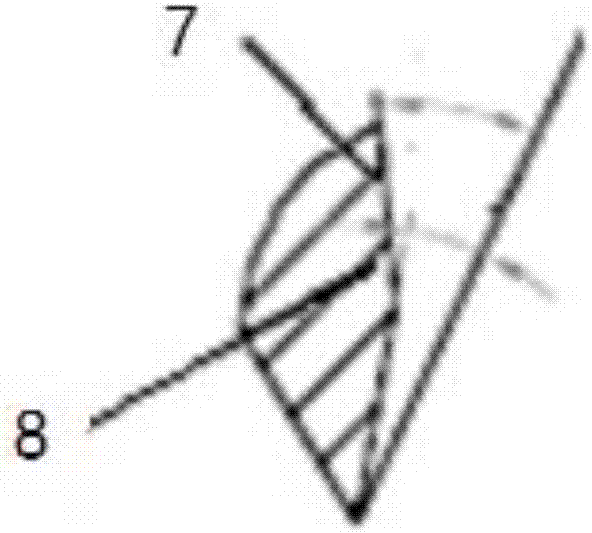

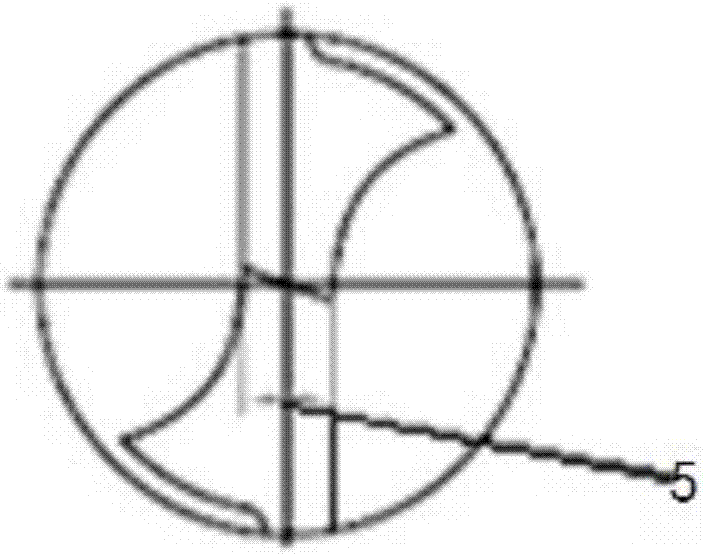

[0031] like Figure 1~Figure 4 As shown, the single chip flute double cutting edge drill bit includes a drill shank 1 and a drill edge 2, the drill shank 1 and the drill edge 2 are connected by a connecting part 3, and the free end of the drill edge 2 is the drill tip 4, so The position of the drill edge 2 close to the drill tip 4 is provided with a double helical cutting edge groove 5 , and the position of the drill edge 2 close to the connecting portion 3 is provided with a single helical chip removal groove 6 . T...

Embodiment 2

[0049] The only difference between this embodiment and Embodiment 1 is that the helix angle α of the double helical cutting edge groove 5 and the single helical chip flute 6 are the same and both are 35°; the drill edge 2 and the double helical cutting edge have the same helix angle α. The ratio of the length of the uncut portion 9 connected with the groove 5 to the length of the double helical cutting edge groove 5 is 1.10.

Embodiment 3

[0051] The only difference between this embodiment and the first embodiment is that the helix angle α of the double helical cutting edge groove 5 and the single helical chip flute 6 is the same and both are 45°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle α | aaaaa | aaaaa |

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com