Sensor assembly and method for manufacturing sensor assembly

A technology of sensor components and manufacturing methods, applied in the direction of instruments, power metering, measuring devices, etc., capable of solving problems such as reduced reliability of magnetic sensor circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach

[0094] Hereinafter, the third embodiment will be described focusing on points different from the first embodiment with reference to the drawings.

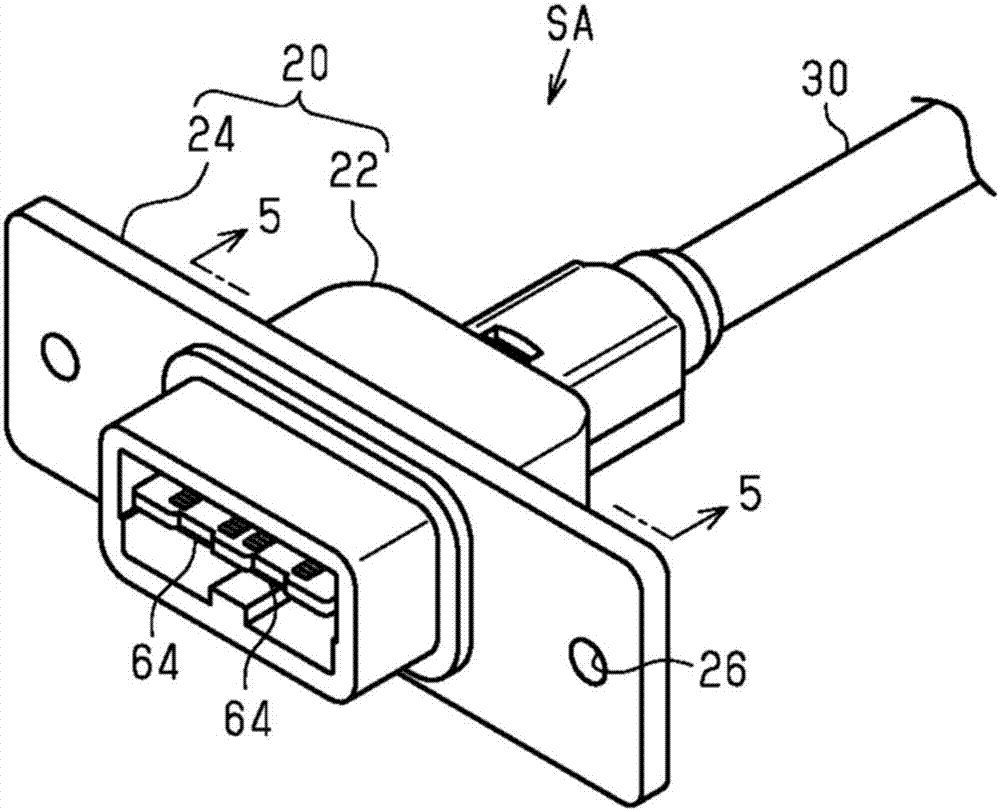

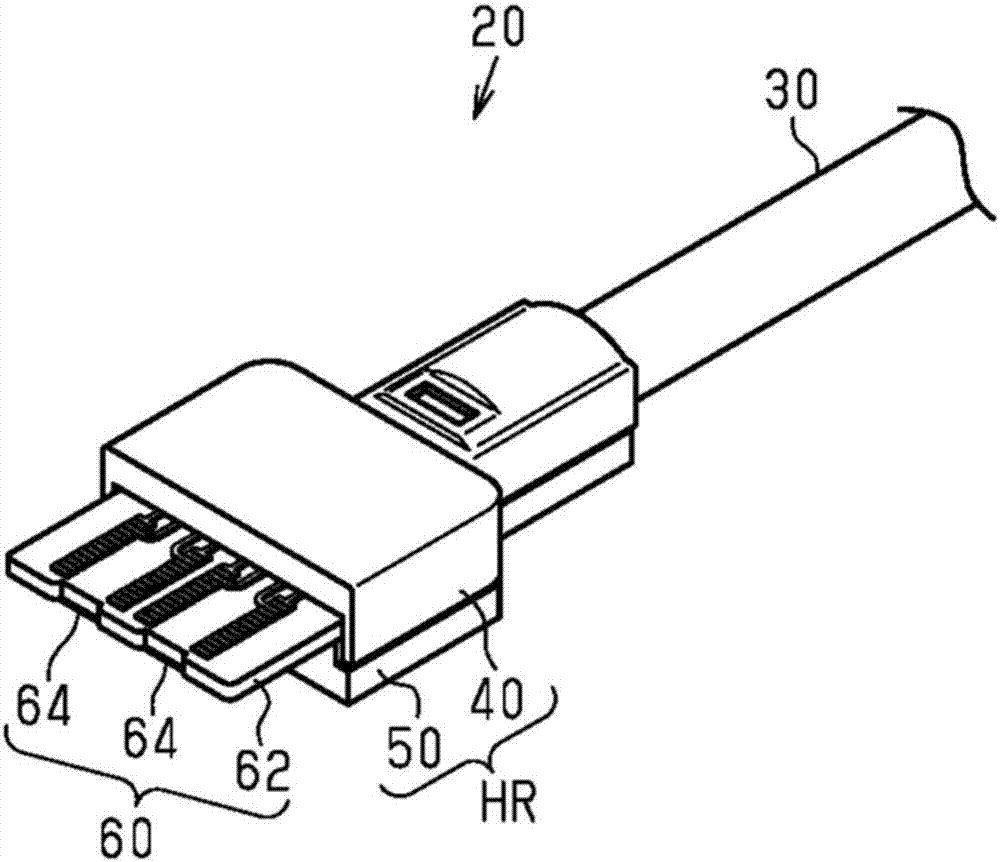

[0095] Figure 9 A cross-sectional structure of the holder HR according to this embodiment is shown in . In addition, in Figure 9 in, for image 3 Components corresponding to those shown in FIG. 2 and 4 are denoted by the same reference numerals for convenience. Such as Figure 9 As shown, in the present embodiment, the holder HR is integrally formed of the sensor housing part SH in which a part of the magnetic sensor circuit 60 is housed, and the harness housing part HH in which a part of the wire harness 30 is housed. Specifically, the sensor housing part SH and the harness housing part HH are configured by the first holder part 40 and the second holder part 50 . Here, the first holder portion 40 of the harness housing portion HH extends in a direction opposite to the direction in which the substrate 62 protrudes from the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com