Intermittent negative-pressure taking type grain moisture detection equipment

A detection equipment, intermittent technology, applied in the field of grain moisture detection equipment, intermittent negative pressure retrieving type grain moisture detection equipment, can solve the problem of being easily disturbed by the external environment, difficult to control the fullness of the seeds to be detected, and the detection of seed moisture Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

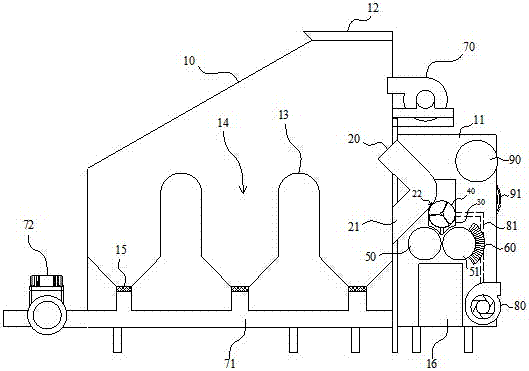

[0015] Such as figure 1 As shown, the present invention provides an intermittent negative pressure reclaiming type grain moisture detection device, which includes a housing 10, a material inlet 12 is arranged above the housing 10, and a plurality of collecting bins 14 are arranged at intervals on the housing 10. A blower 70 is provided on the side of the body 10 below the material inlet 12, and a moisture detection device 11 is provided on the outside of the housing 10 near the blower 70. In this solution, the housing 10 can be used as an independent drying silo or a grading and screening material. warehouse. In the above scheme, the grain (seed) material enters the shell 10 from the material inlet 12, and then the hot air is blown into the shell 10 through the blower 70 to heat the material, and due to the different fullness of the seed particles, the blower 70 Under the wind, it will fall into different collection bins 14 according to the fullness. The full particles will nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com