Reactor boron concentration sampling corollary equipment

A technology of supporting equipment and boron concentration, applied in the field of nuclear power plant sampling, can solve the problems of reducing the radiation time of sampling personnel, and achieve the effect of high density and excellent radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

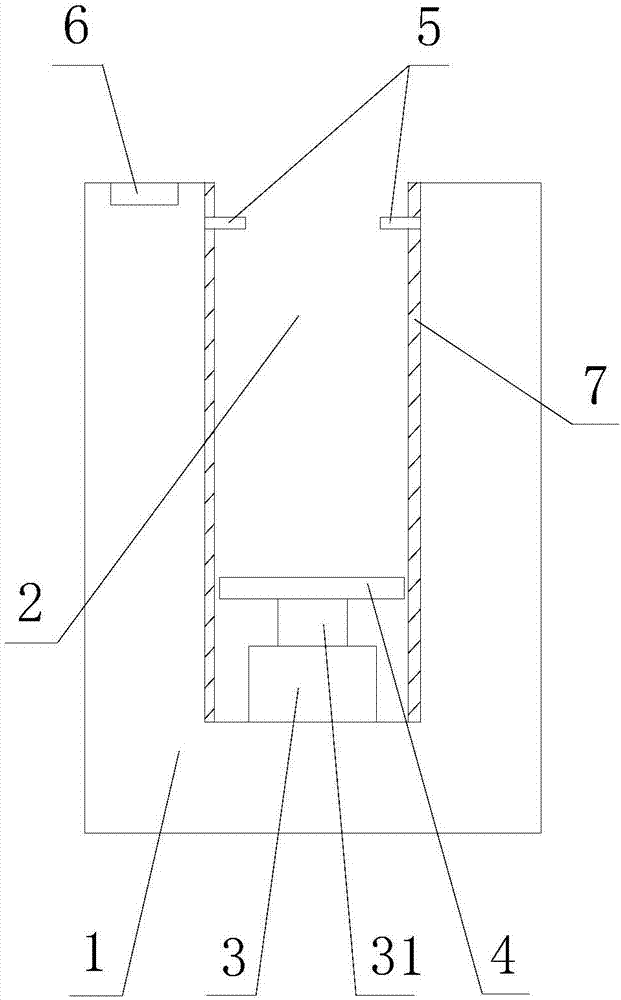

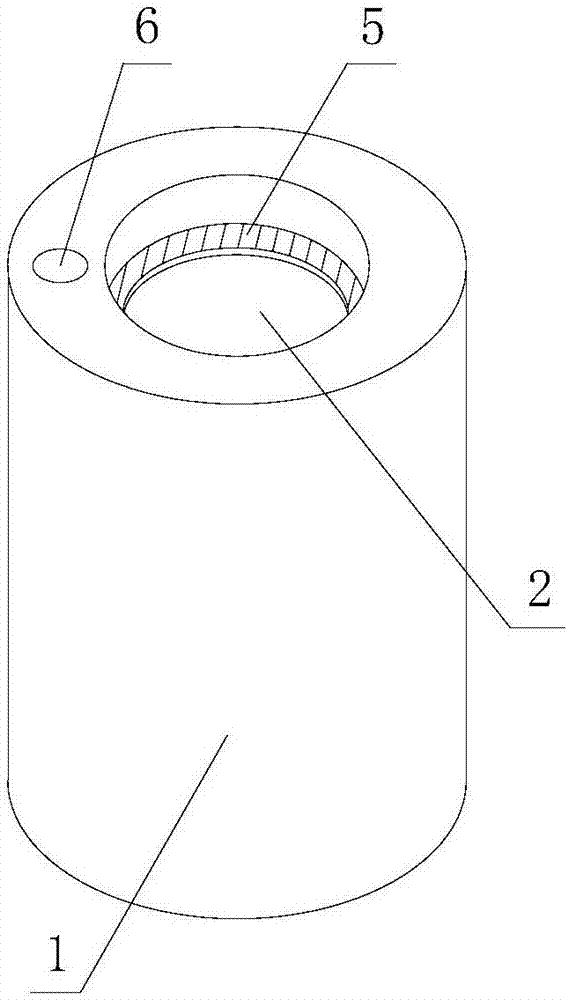

[0023] like figure 1 and figure 2 The reactor boron concentration sampling supporting equipment shown includes an operation table 1 whose bottom surface and top surface are parallel to each other, a groove 2 is arranged on the top surface of the operation table 1, and a driving device 3 with a driving end 31 upward is arranged inside the groove 2. Fixed plate 4 is fixed on the driving end 31, and the upper surface of described plate 4 is parallel to the top surface of operating table 1; The surface of the flat plate 4, and the width of the rubber belt 5 is 2 cm; the top surface of the operating table 1 is also fixed with a level 6. The level 6 is embedded on the top surface of the console 1 . The level 6 is an electronic level. The driving device 3 is an air cylinder. The groove 2 is cylindrical, and the rubber band 5 is circular. The surface of the inner wall of the groove 2 is coated with a metallic lead coating 7 . The bottom surface and the top surface of the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com