Cover plate having anti-dizzy function and manufacturing method thereof, and display panel

A production method and cover plate technology are applied in the direction of photo-engraving process, optics and opto-mechanical equipment of the pattern surface, which can solve the problems of people's reading troubles and the application is not common, and achieve the improvement of the picture display quality, the production method is simple, The effect of reducing the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

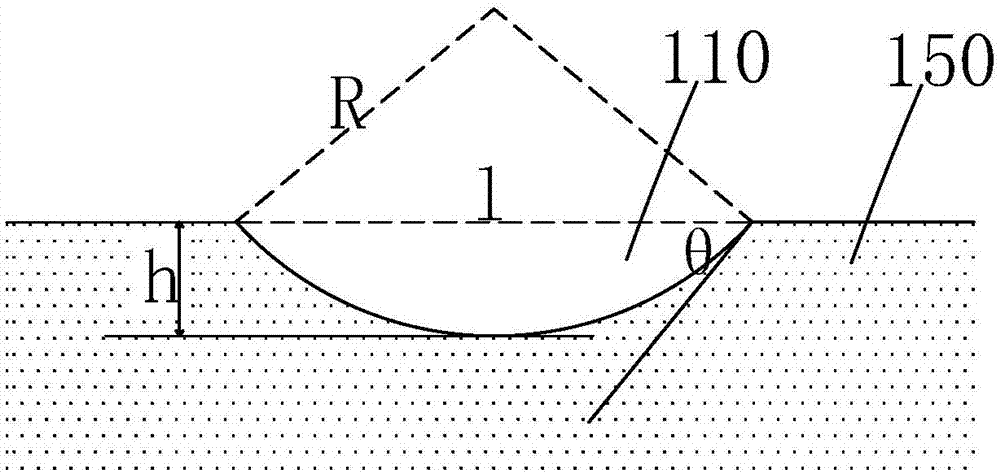

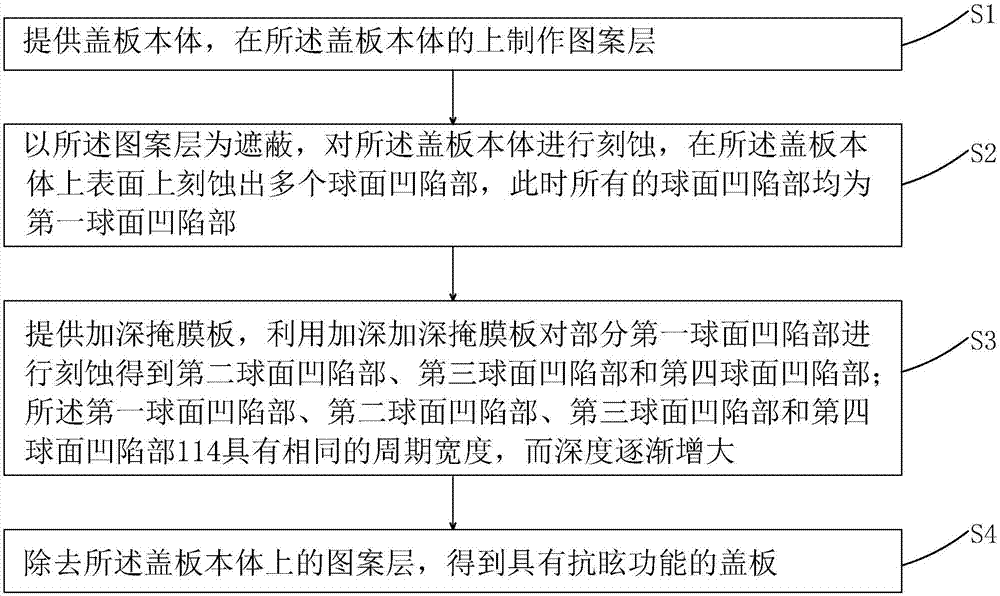

[0071] see figure 2 , based on the above-mentioned method for manufacturing a cover with anti-glare function, the present invention also provides a method for manufacturing a cover with anti-glare function, the first embodiment of which specifically includes the following steps:

[0072] Step S1, such as Figure 3-4 As shown, a cover body 150 is provided, and a pattern layer 250 is fabricated on the cover body 150 .

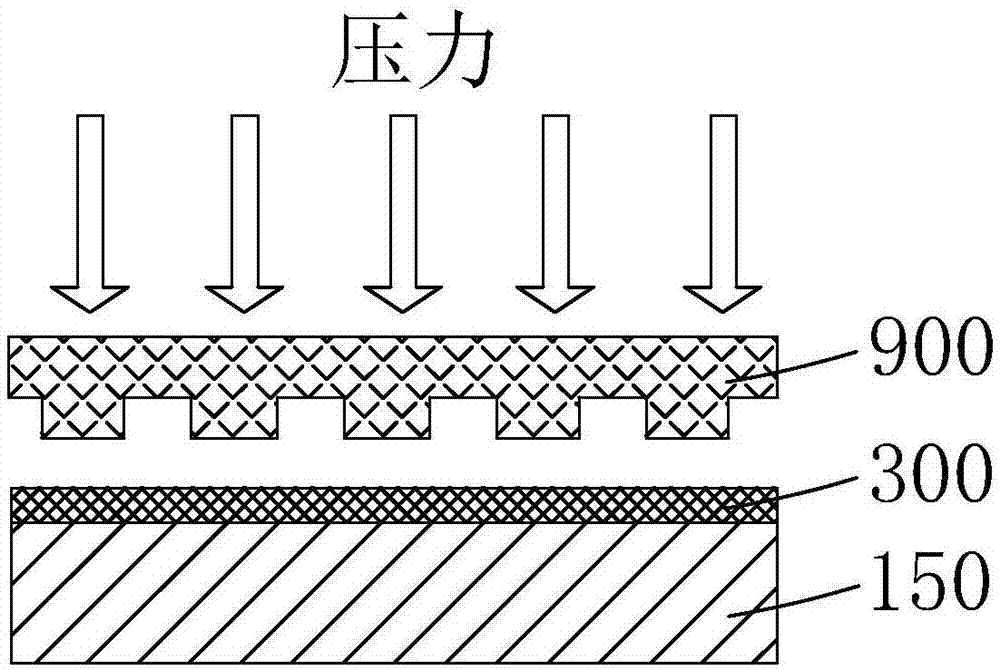

[0073] Specifically, in this embodiment, the cover body 150 provided in step S1 is a glass cover. Then in the step S1, the process of making the pattern layer 250 on the cover body 150 is as follows: cleaning the upper surface of the cover body 150, and coating a layer of embossing glue 300 on it, and using The prepared embossing template 900 is used to emboss the layer of embossing glue 300 and release the mold to obtain the pattern layer 250 .

[0074] Step S2, such as Figure 5 As shown, the cover body 150 is etched with the pattern layer 250 as a shield,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com