Casting mold

一种模具、横模的技术,应用在制造工具、铸造成型设备、铸型等方向,能够解决热膨胀小等问题,达到提高设计自由度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

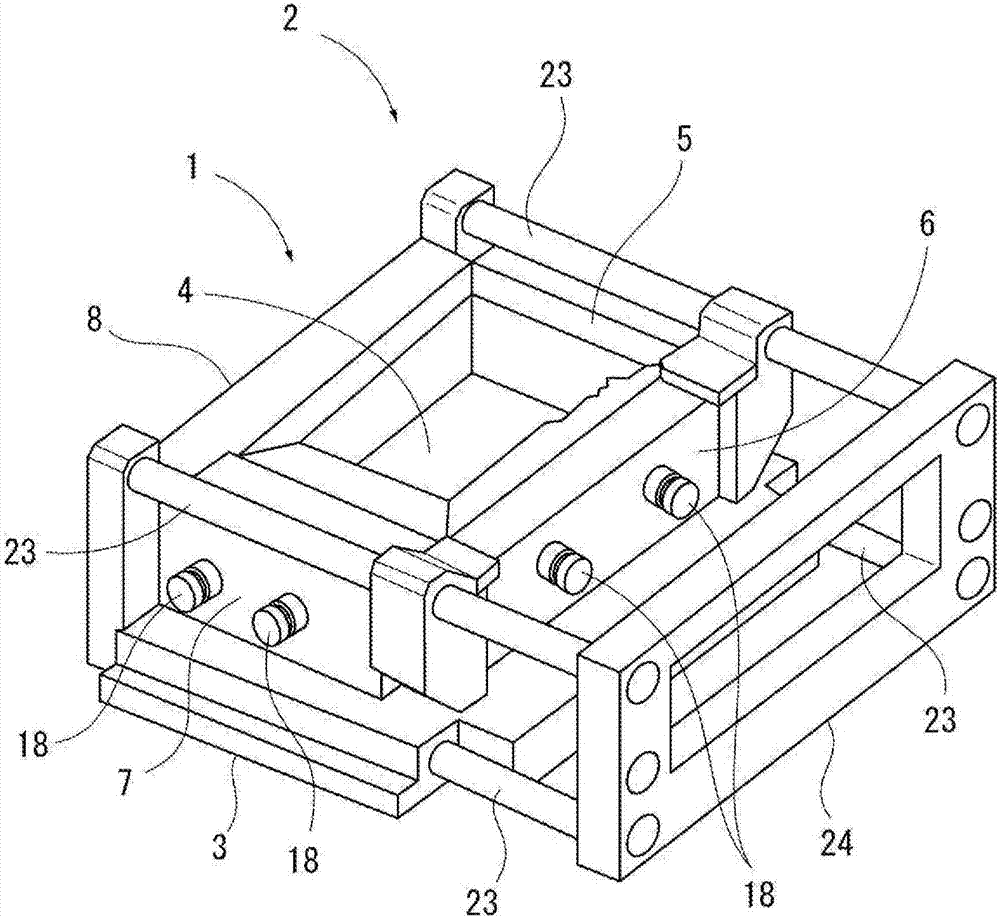

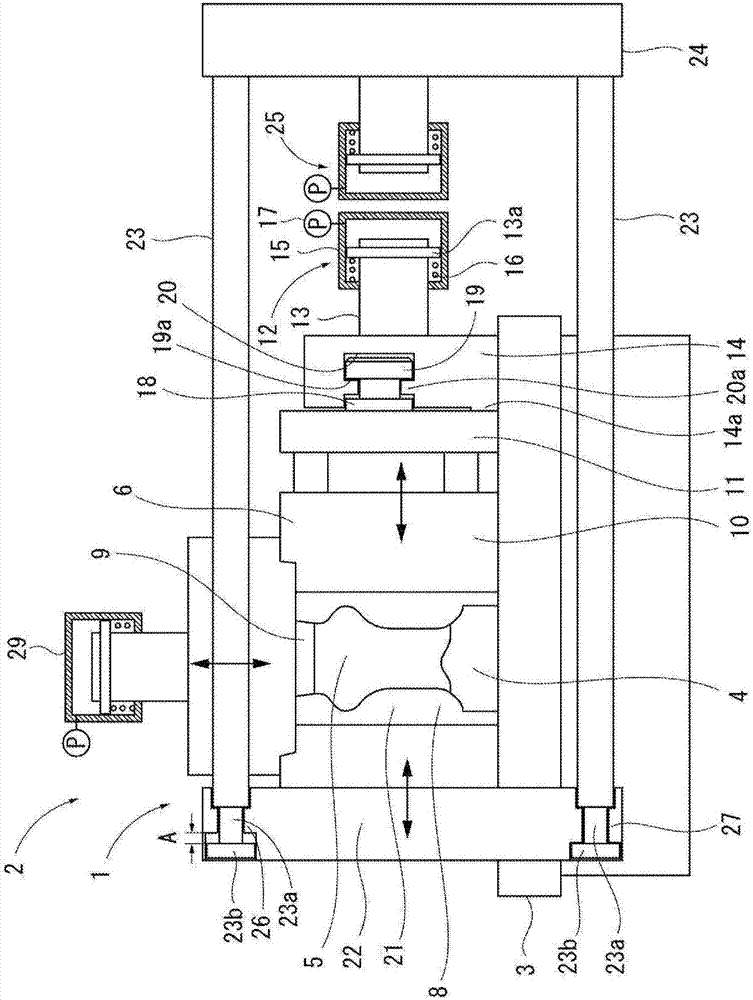

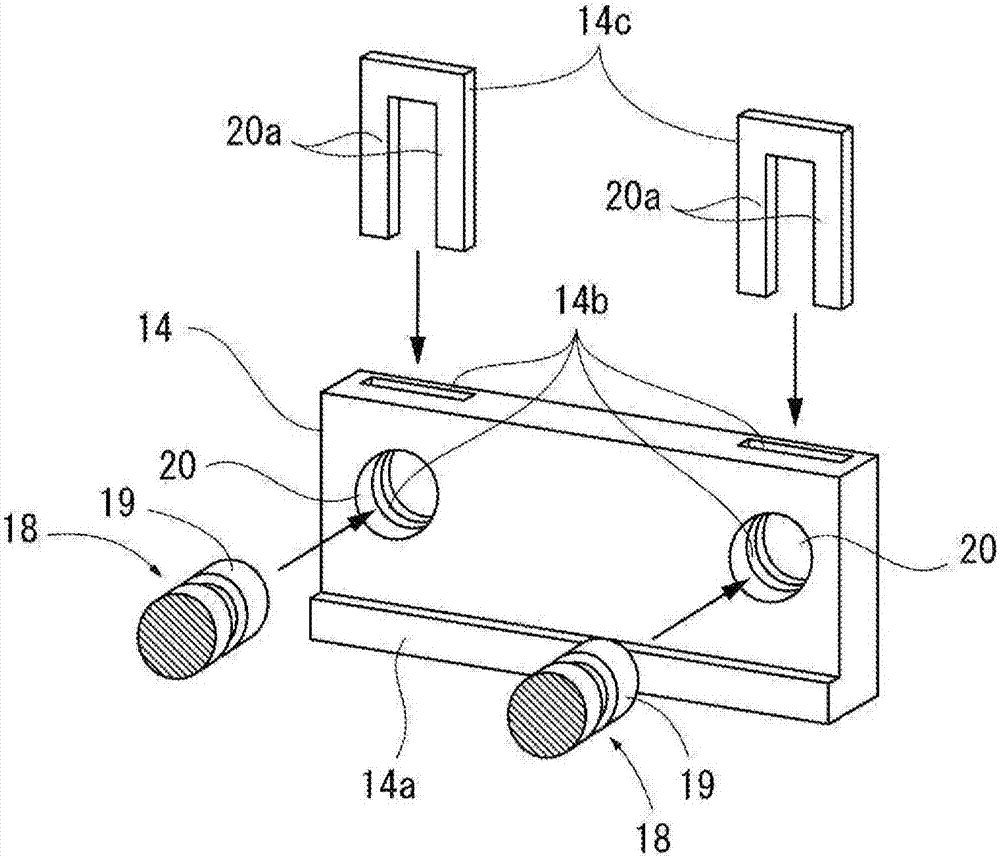

[0023] refer to Figure 1 to Figure 3 , a casting mold according to an embodiment of the present invention will be described.

[0024] refer to figure 1 , the casting mold 1 of the present embodiment constitutes a main part of the casting machine 2 . The casting machine 2 casts a cylinder head of an automobile engine by a low pressure casting method.

[0025] The casting machine 2 includes a base 3 on which the mold 1 is arranged. The mold 1 includes a lower mold 4 that is fixed to the base 3 , and first to fourth sliding transverse molds 5 to 8 , which are arranged to surround the base 3 in four directions from the side surface of the lower mold 4 . Lower die 4; and upper die 9 (refer to figure 2 ), which is arranged so as to cover the space from above the space defined by the lower mold 4 and the first to fourth sliding transverse molds 5 to 8 . The first to fourth sliding transverse molds 5 to 8 are slidable from the mold opening position to the mold closing position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com