A hub cover film coating robot

A technology of robots and hubcaps, applied in the field of mechanical devices, can solve the problems of low efficiency and difficult to guarantee the quality of film packaging, and achieve the effect of high efficiency, good film laying quality, and avoiding being involved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

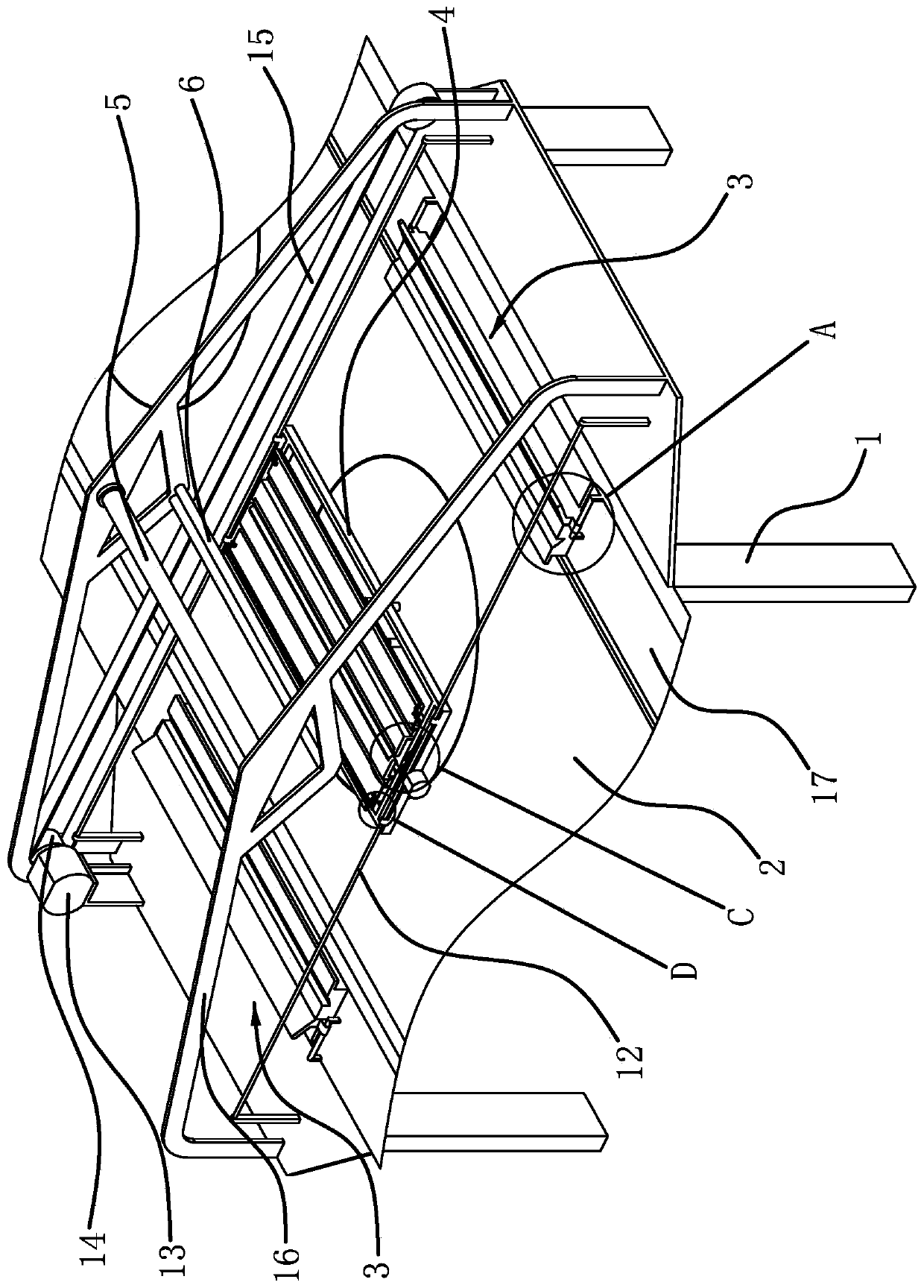

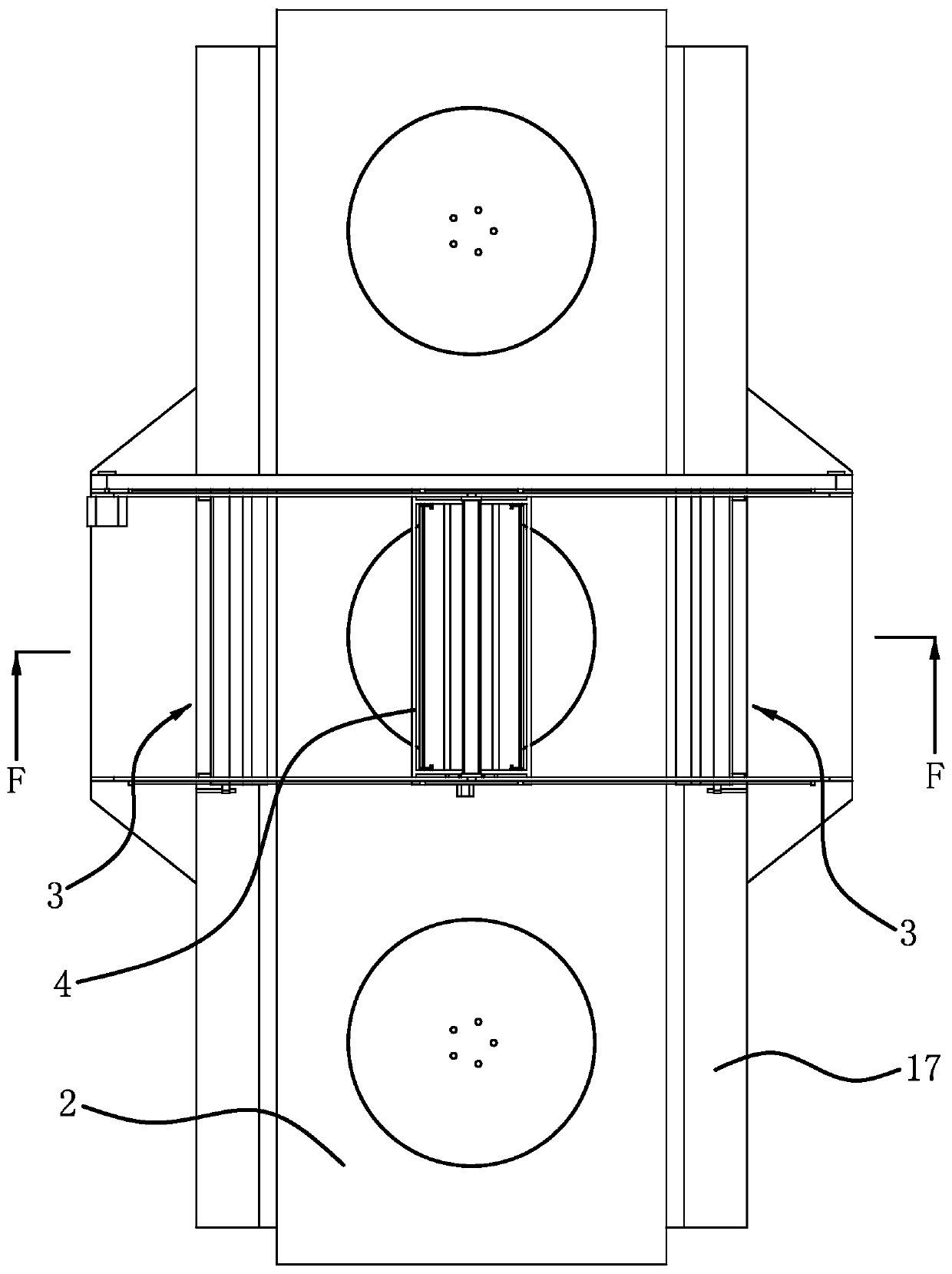

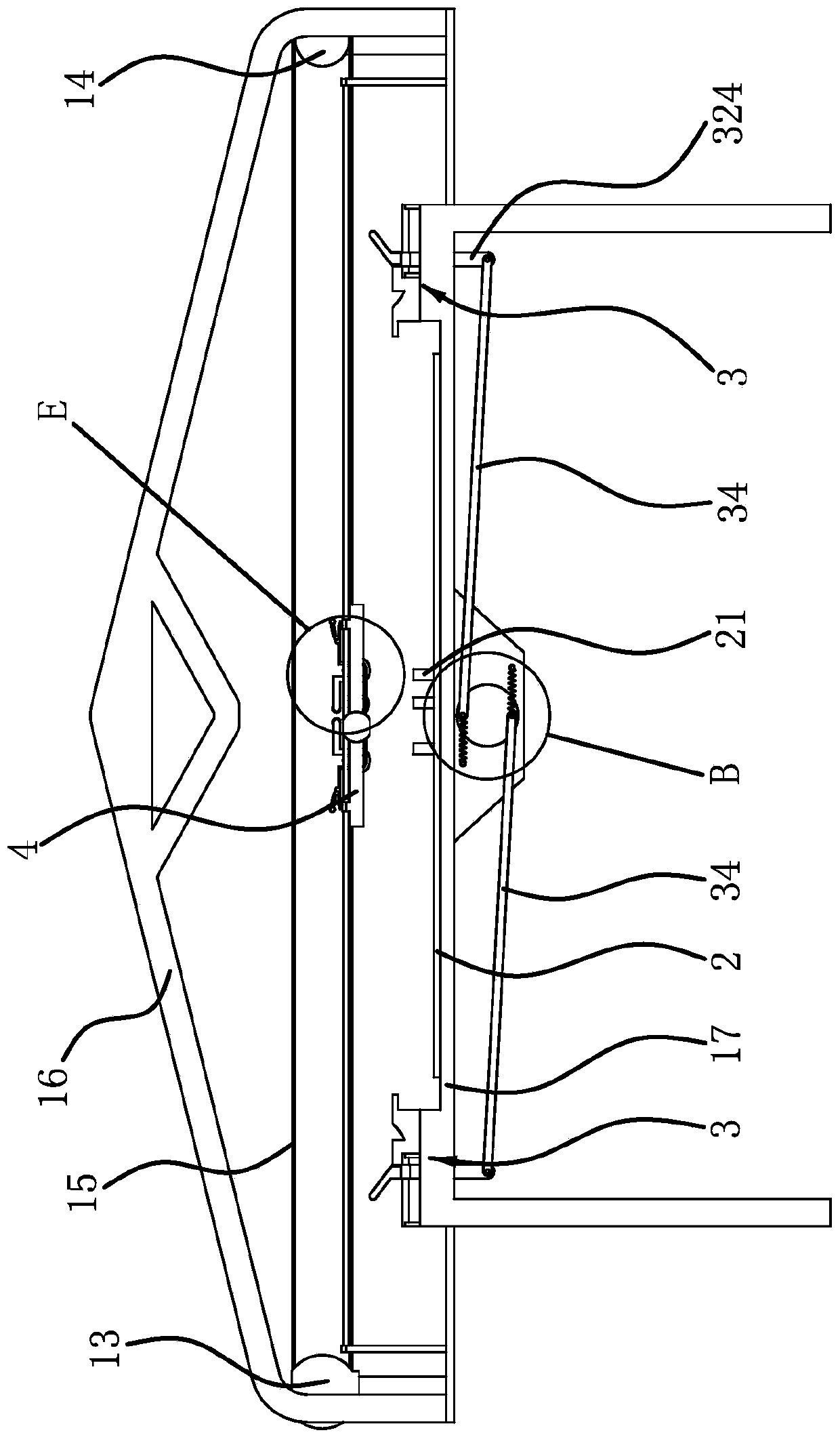

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a hubcap film coating robot includes a frame 1 and a conveyor belt 2 arranged longitudinally and used for laying the hubcap. The frame 1 is horizontally fixed with a supporting platform 17, and the upper layer of the conveyor belt 2 is laid on the supporting platform. 17, there are several stations on the outer surface of the conveyor belt 2, and each station has a number of bolt holes for the hub cap to be set on the positioning column 21, and the hub cover is positioned by the positioning column 21, so that its position can be maintained accurately and securely. Stablize. The frame 1 is longitudinally provided with positioning rollers 5 for position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com