A kind of polycrystalline mosaic board and preparation method thereof

A mosaic and polycrystalline technology, applied in chemical instruments and methods, other household utensils, synthetic resin layered products, etc., can solve the problems of glass mosaic panels such as monotonous appearance, slipping, and glaze fading easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

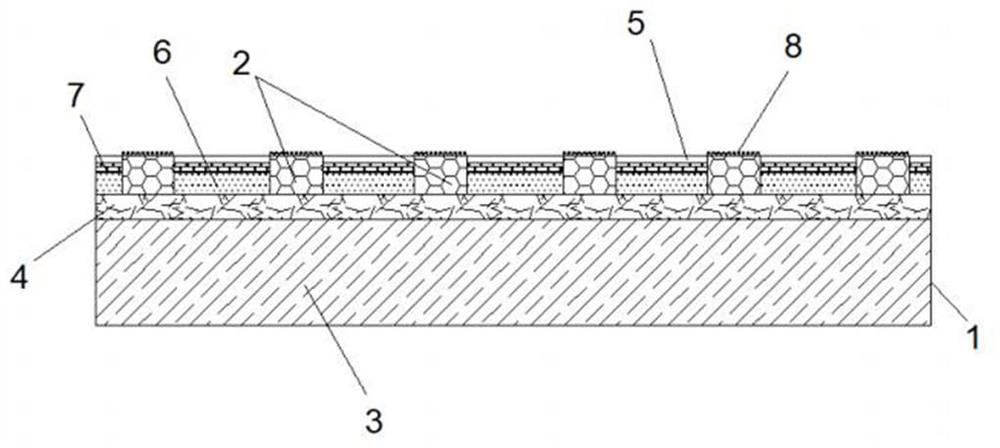

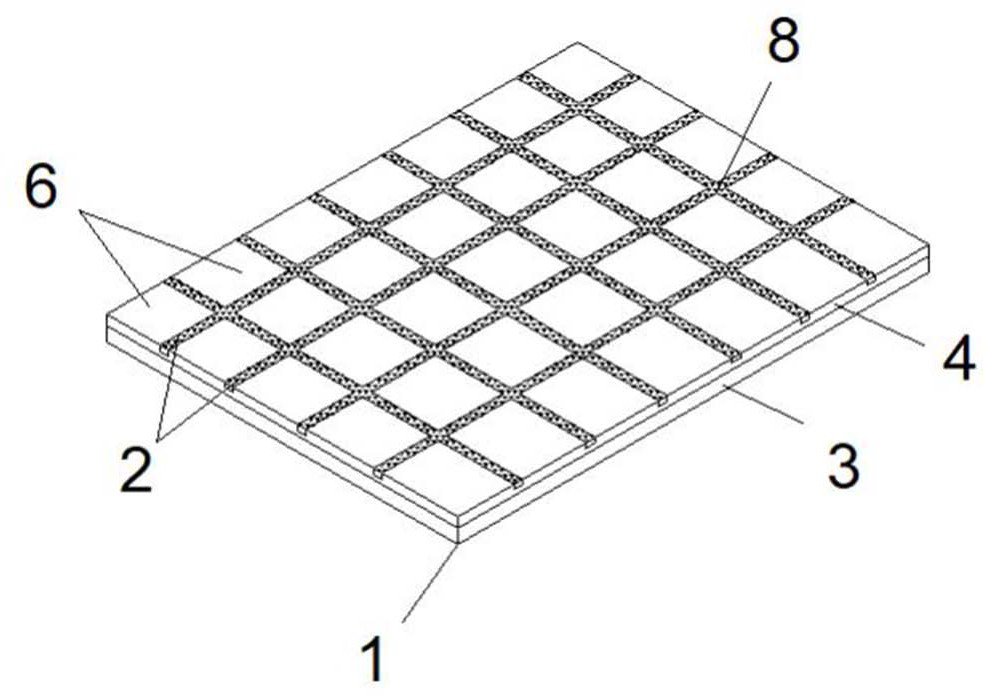

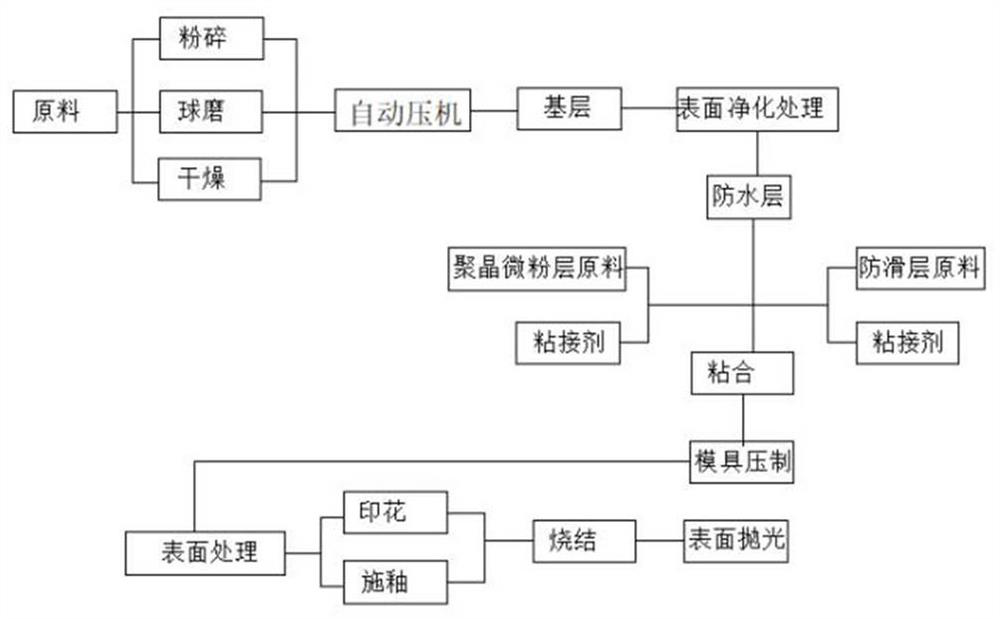

[0028] A kind of preparation method of polycrystalline mosaic board, concrete steps are as follows;

[0029] Step 1: Preparation of the base material, weighing silicate, clay, quartz, fluoride, antibacterial agent, magnesite, talc, anhydrous borax, pyrophyllite, spodumene and beryl according to the proportion, and then by mixing , crushing, ball milling and drying to obtain the mixture powder of the base layer, and then put the mixture powder into the automatic press to make the base layer embryo mold. The thickness, length and width of the base layer embryo mold can be customized according to the needs, and the obtained base layer embryo mold stand-by;

[0030] Step 2: Preparation of the waterproof layer material, mixing and stirring acrylic latex, Portland cement, sodium chloride, polyurethane resin and heavy calcium carbonate on the top of the base mold in step 1, and then drying;

[0031] Step 3: Preparation of polycrystalline layer material, 56% of silicon oxide, 24% of ...

Embodiment 1

[0036] Raw material formula:

[0037] Base: 40 parts of silicate, 20 parts of clay, 15 parts of quartz, 5 parts of fluoride, 10 parts of antibacterial agent, 3 parts of magnesite, 1 part of talc, 1 part of anhydrous borax, 1 part of pyrophyllite, spodumene 1 part of stone and 1 part of beryl;

[0038] Waterproof layer: 25 parts of acrylic latex, 30 parts of Portland cement, 1 part of sodium chloride, 5 parts of polyurethane resin and 5 parts of ground calcium carbonate;

[0039] Anti-slip layer: 20 parts of diatomite, 15 parts of kaolin, 12 parts of red mud, 12 parts of titanium dioxide, 12 parts of expanded perlite powder, 8 parts of magnesium oxide, 8 parts of magnesium chloride, 8 parts of aluminum oxide, 3 parts of alum, triethanolamine 2 parts and 4 parts of nano silicon dioxide and adhesion promoter;

[0040] Polycrystalline layer: silicon oxide 56%, aluminum oxide 24%, sodium oxide 4%, potassium oxide 6%, calcium oxide 5%, magnesium oxide 4%, iron oxide 0.5% and titan...

Embodiment 2

[0049] Raw material formula:

[0050] Base: 50 parts of silicate, 30 parts of clay, 17 parts of quartz, 8 parts of fluoride, 12 parts of antibacterial agent, 4 parts of magnesite, 3 parts of talc, 3 parts of anhydrous borax, 3 parts of pyrophyllite, spodumene 3 parts of stone and 3 parts of beryl;

[0051] Waterproof layer: 27 parts of acrylic latex, 33 parts of Portland cement, 4 parts of sodium chloride, 7 parts of polyurethane resin and 7 parts of ground calcium carbonate;

[0052] Anti-slip layer: 25 parts of diatomite, 18 parts of kaolin, 15 parts of red mud, 15 parts of titanium dioxide, 15 parts of expanded perlite powder, 10 parts of magnesium oxide, 10 parts of magnesium chloride, 10 parts of aluminum oxide, 5 parts of alum, triethanolamine 3 parts and 6 parts of nano silicon dioxide and adhesion promoter;

[0053] Polycrystalline layer: silicon oxide 56%, aluminum oxide 24%, sodium oxide 4%, potassium oxide 6%, calcium oxide 5%, magnesium oxide 4%, iron oxide 0.5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com