Lift installation having a compensating device, so that a first roller is largely relieved of loading when the lift car is at rest

A compensating device and elevator technology, which is applied to lifting equipment, elevators, motor vehicles and other directions in mines, and can solve the problems of frequent replacement, large plastic deformation, low effective load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

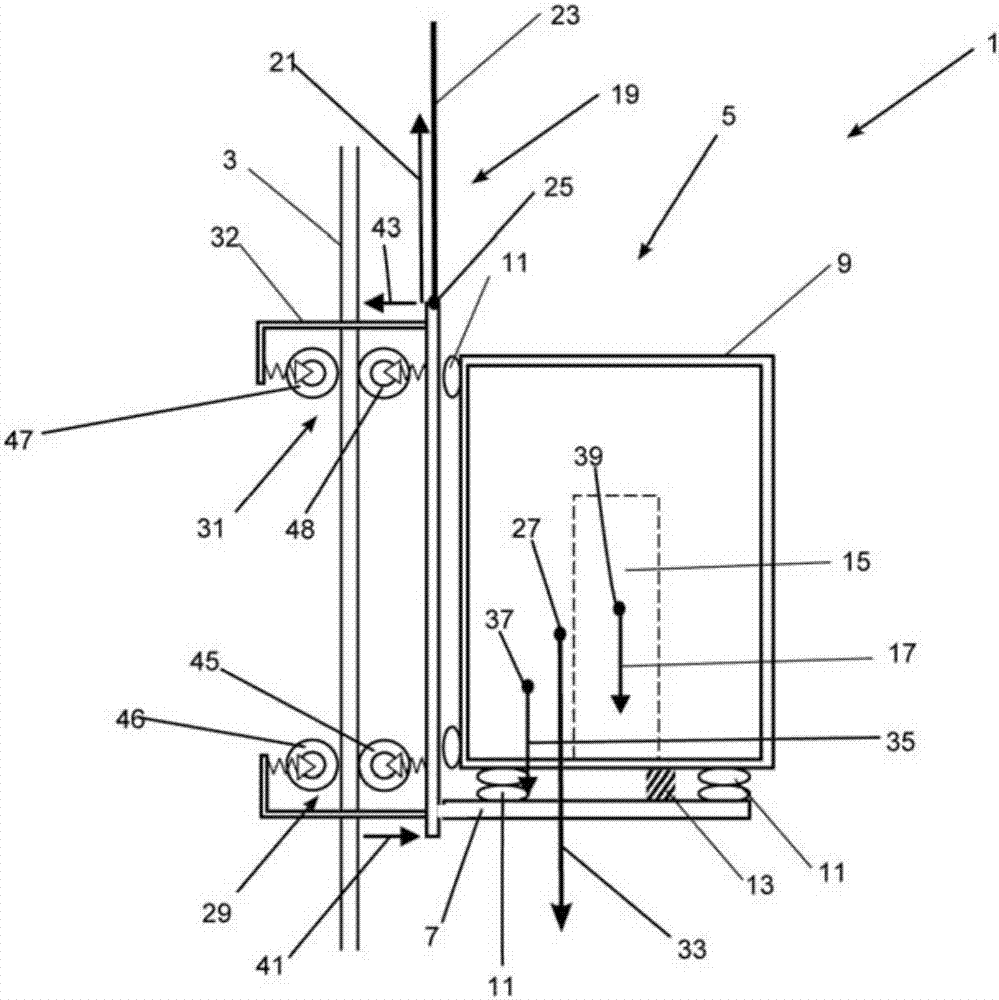

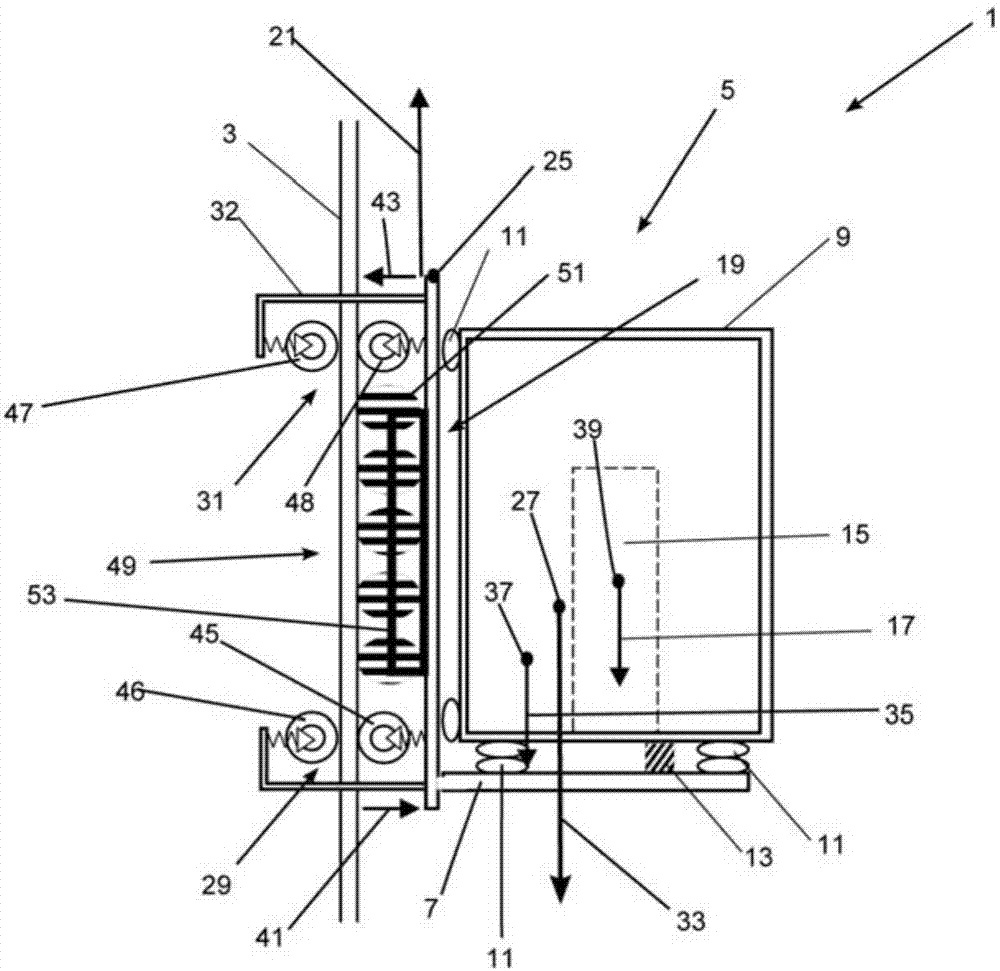

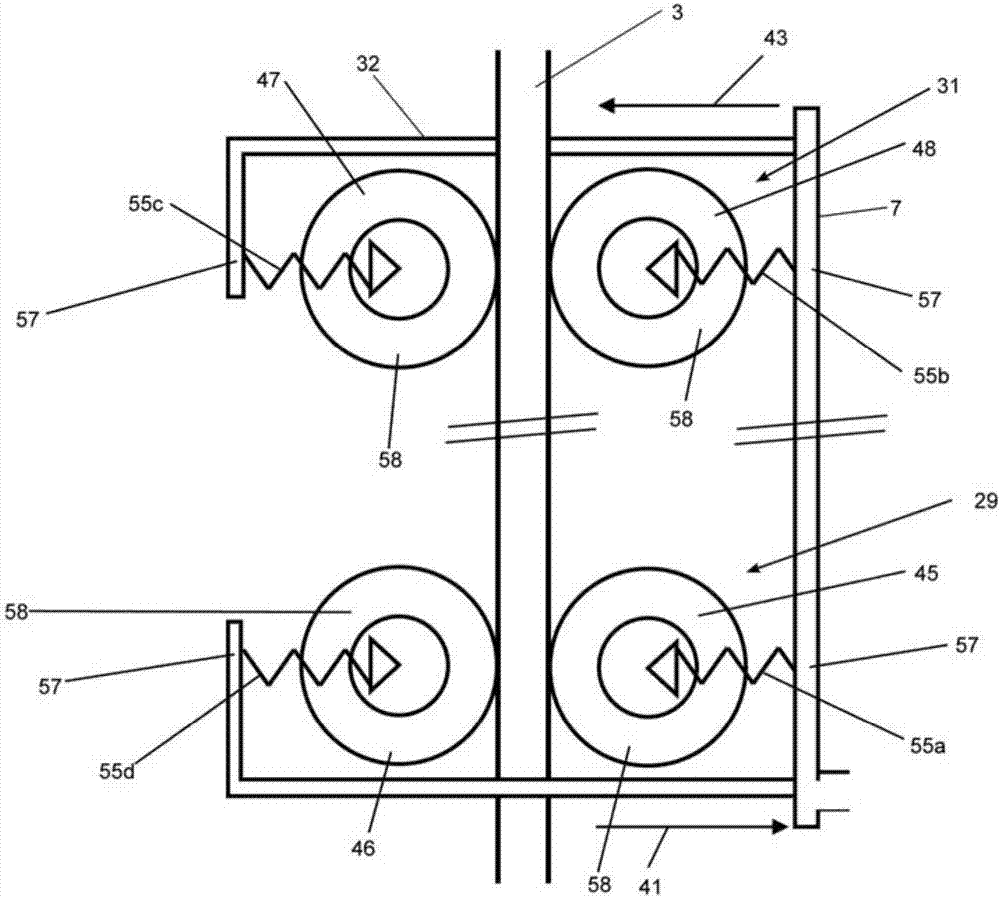

[0033] figure 1 A schematic view of the elevator installation 1 is shown. The elevator installation 1 comprises guide rails 3 and an elevator car 5 . The elevator car 5 is arranged to be movable along the guide rail 3 . To this end, the elevator car 5 comprises a first pair of rollers 29 and a second pair of rollers 31 , wherein the guide rail 3 extends between the two rollers of the first roller pair 29 and between the two rollers of the second roller pair 31 . The two roller pairs 29 and 31 are arranged inside a roller housing 32 .

[0034] In addition, the elevator car 5 comprises a carrier frame 7 carrying an inner car 9 . The weight 33 of the elevator car 5 consists of the weight 17 of the empty elevator car 5 and the payload. The weight 35 of the empty elevator car 5 is applied at the center of gravity 37 of the empty elevator car and the weight 17 of the payload 15 is applied at the center of gravity 39 of the payload 15 .

[0035] A damping element 11 and a weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com