Patents

Literature

36results about "Key-ways measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

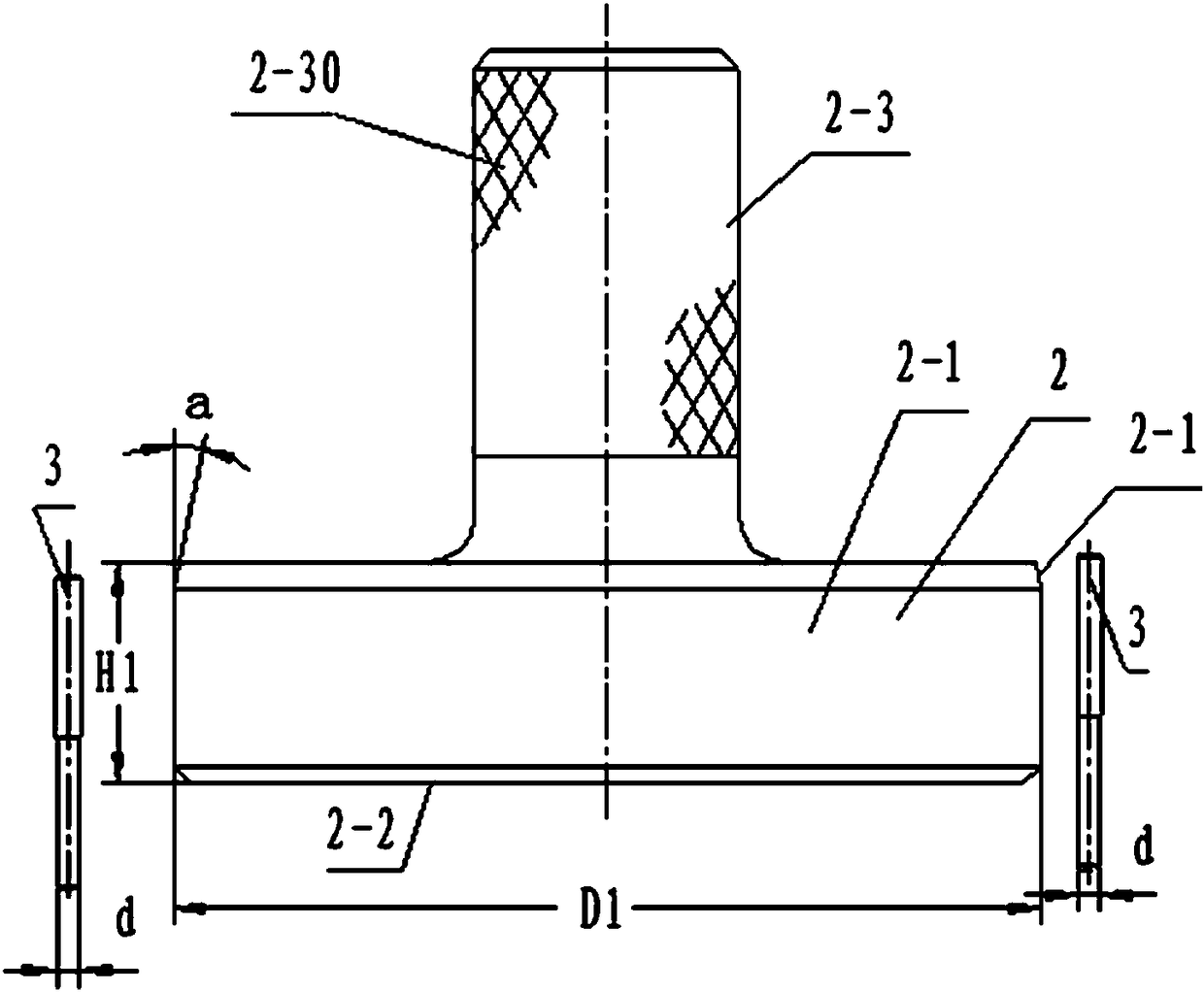

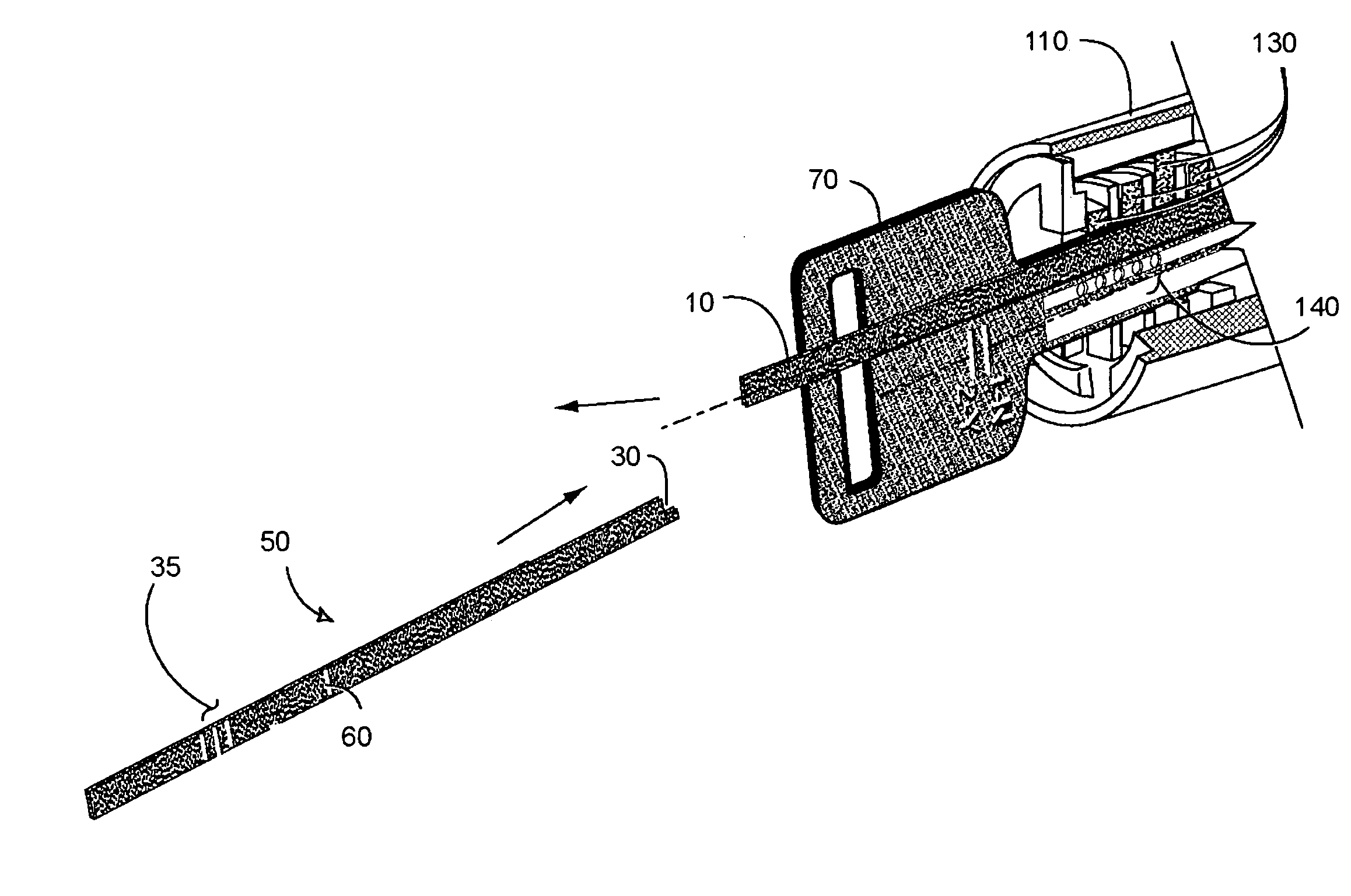

System for identifying and duplicating master keys

ActiveUS10259052B2Analysis is accurate and reliableMaterial analysis by optical meansKey-ways measurementsMeasurement deviceEngineering

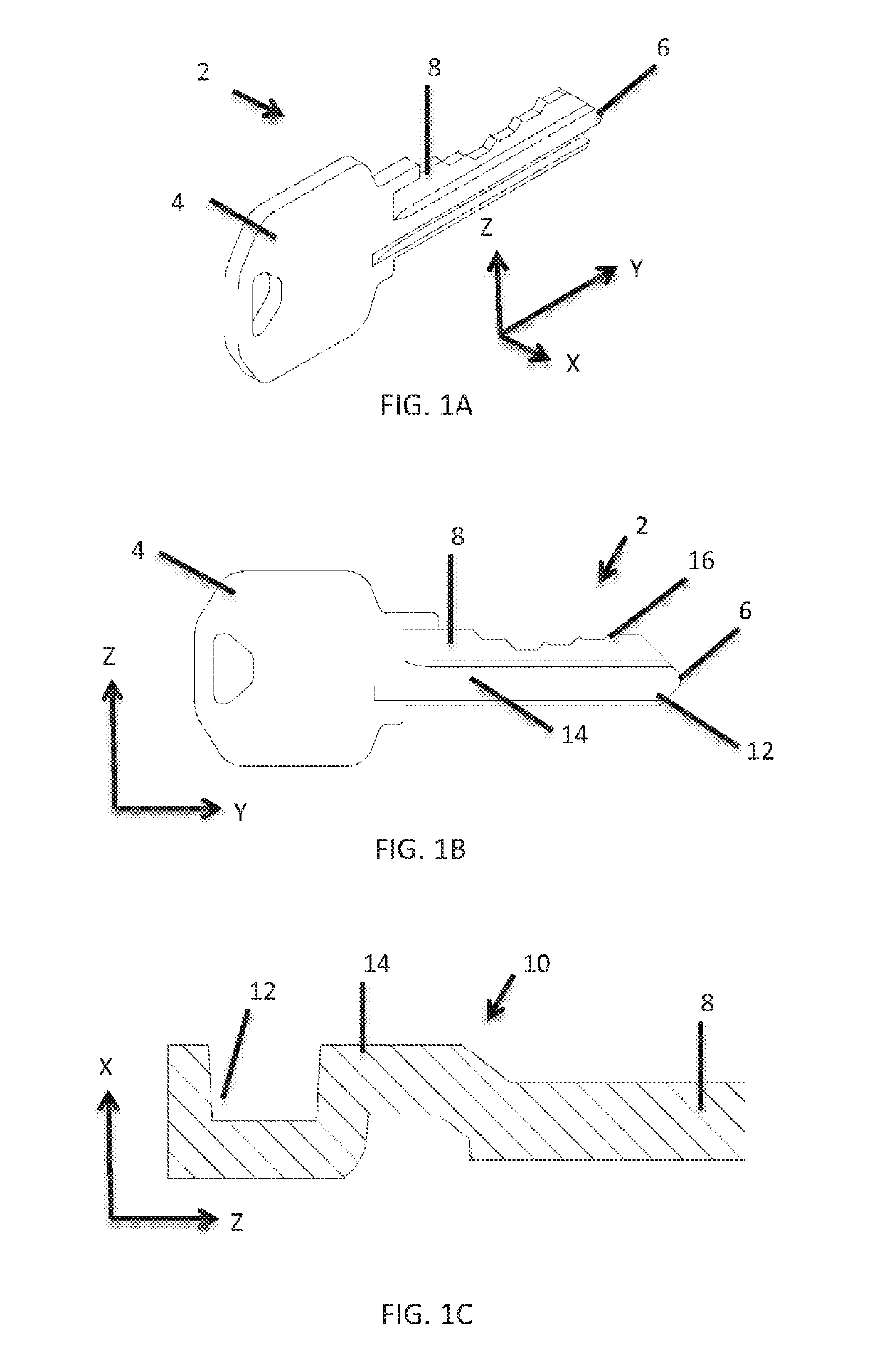

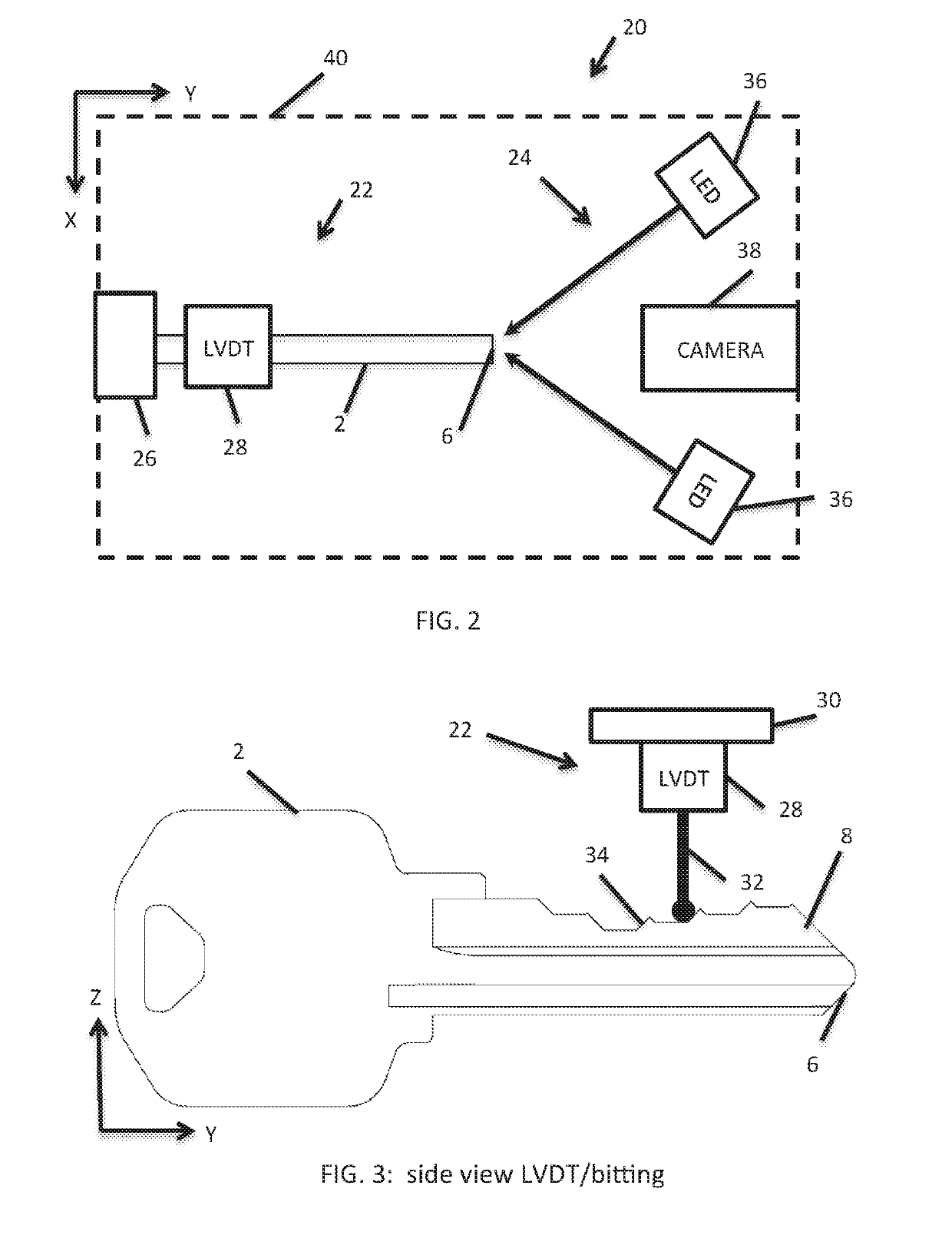

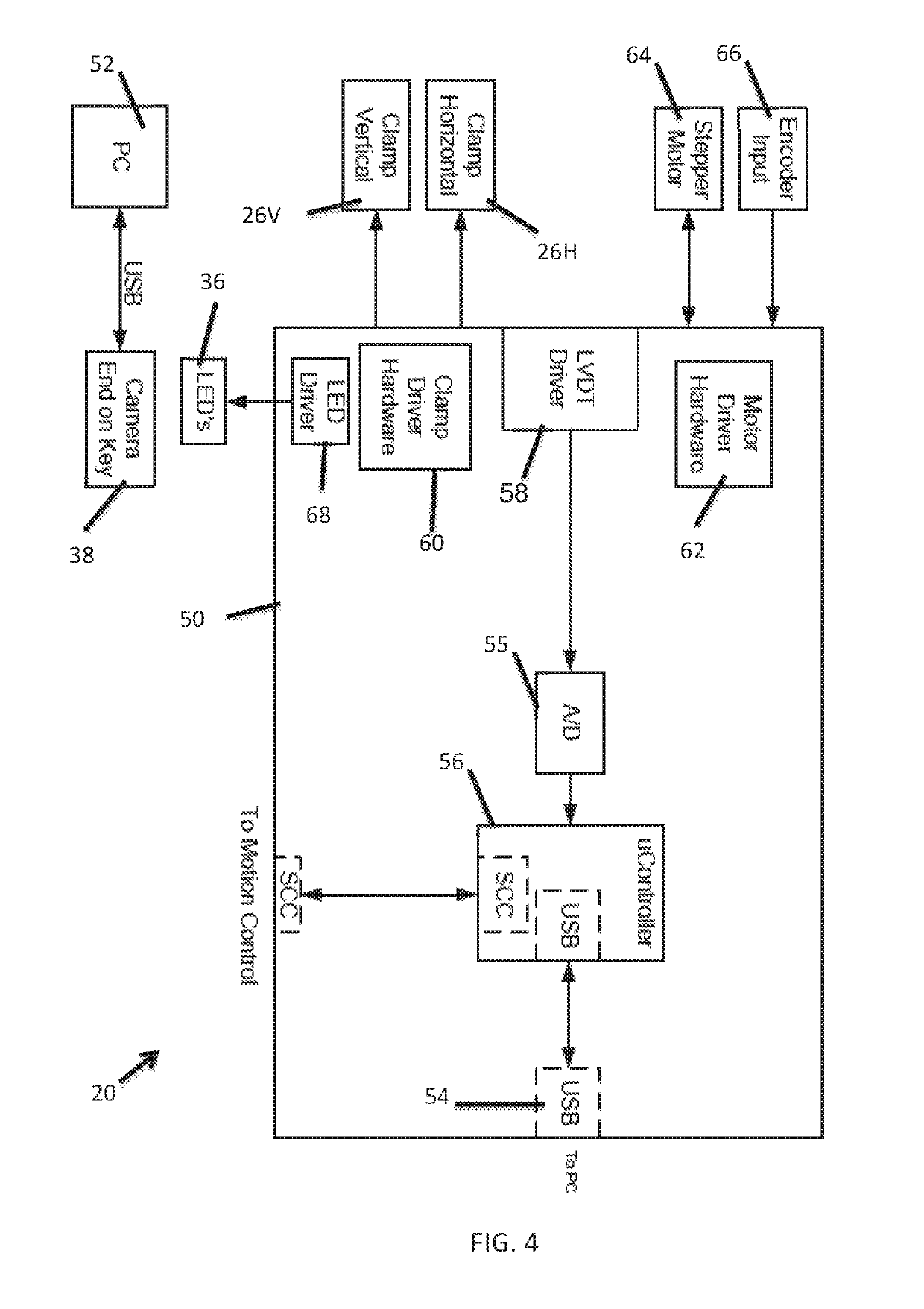

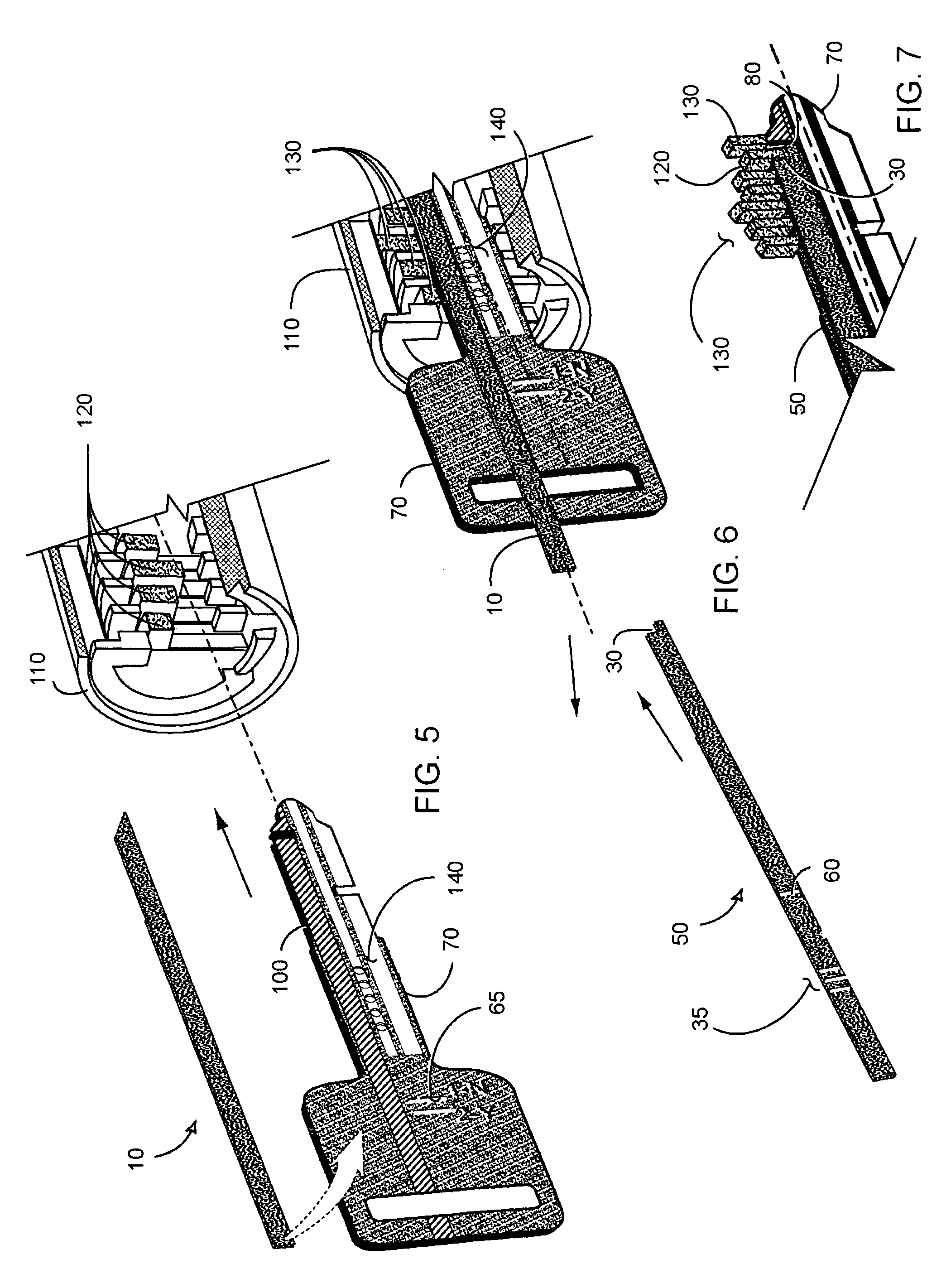

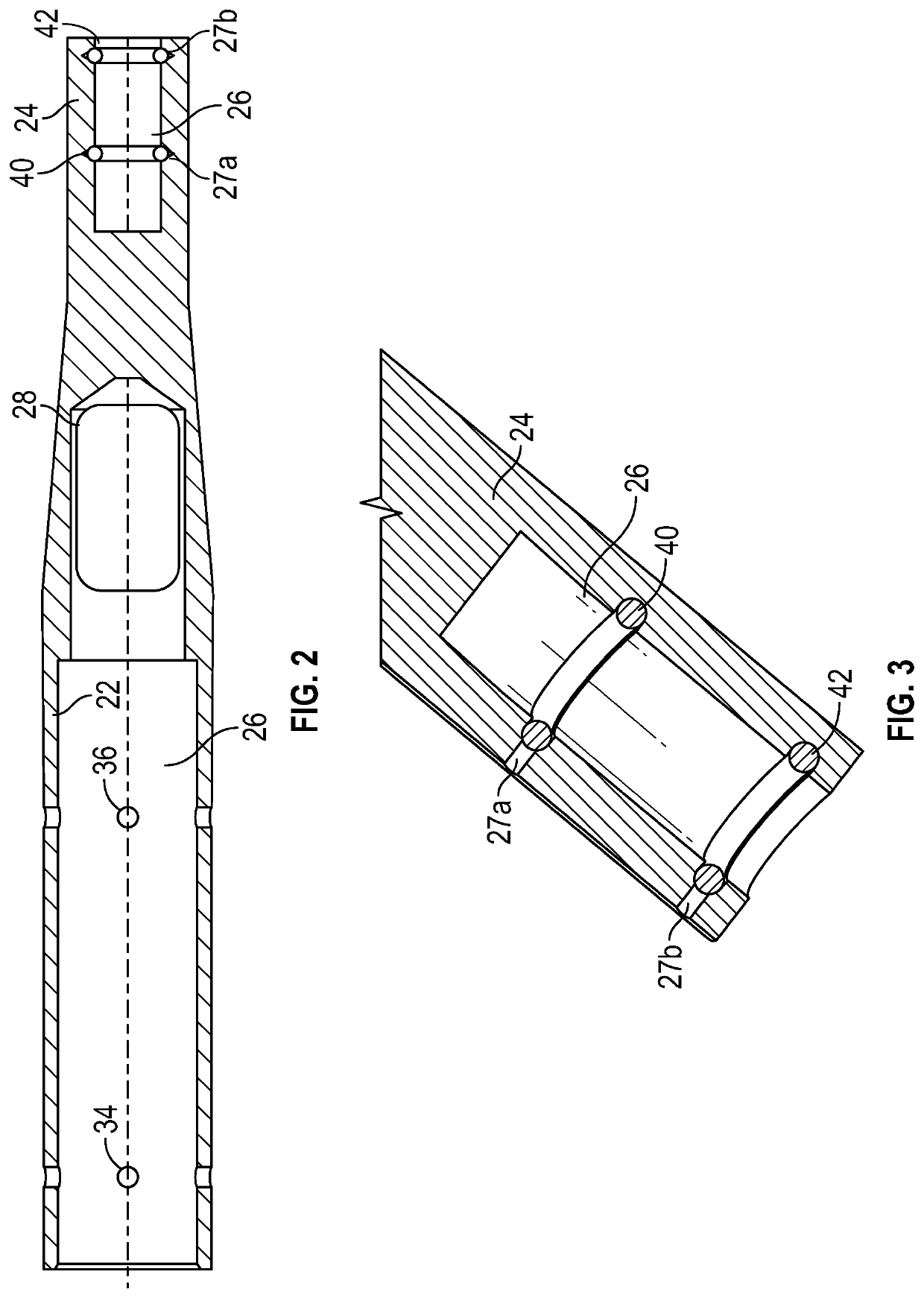

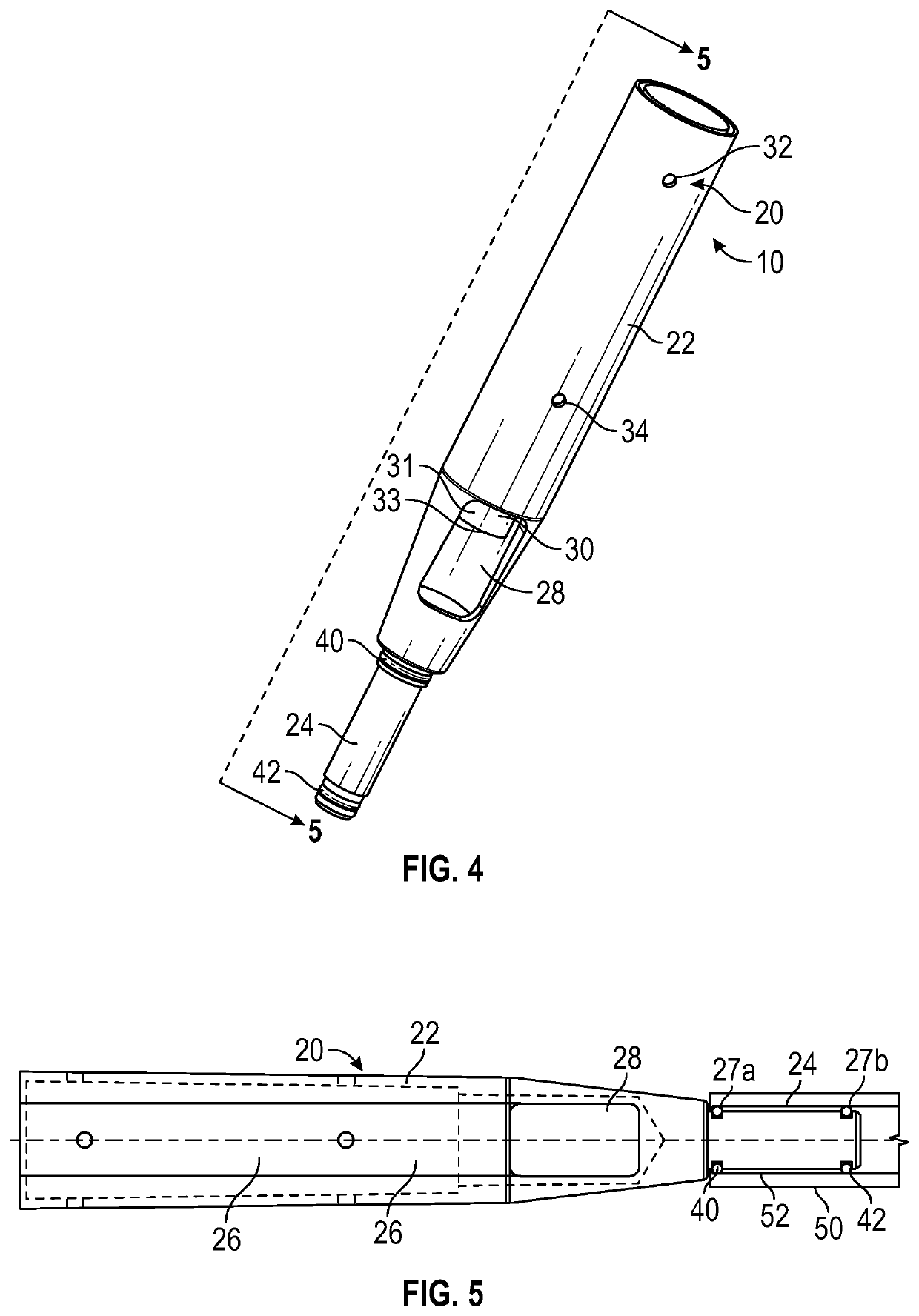

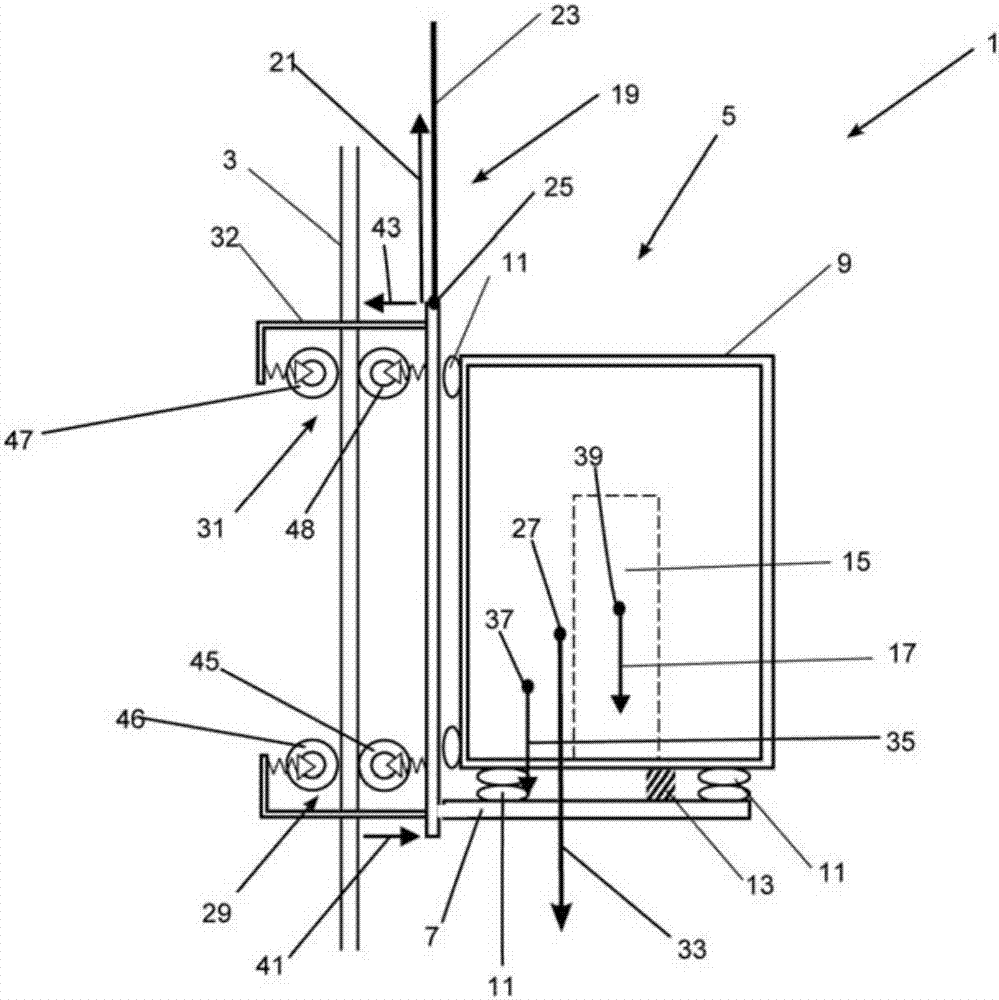

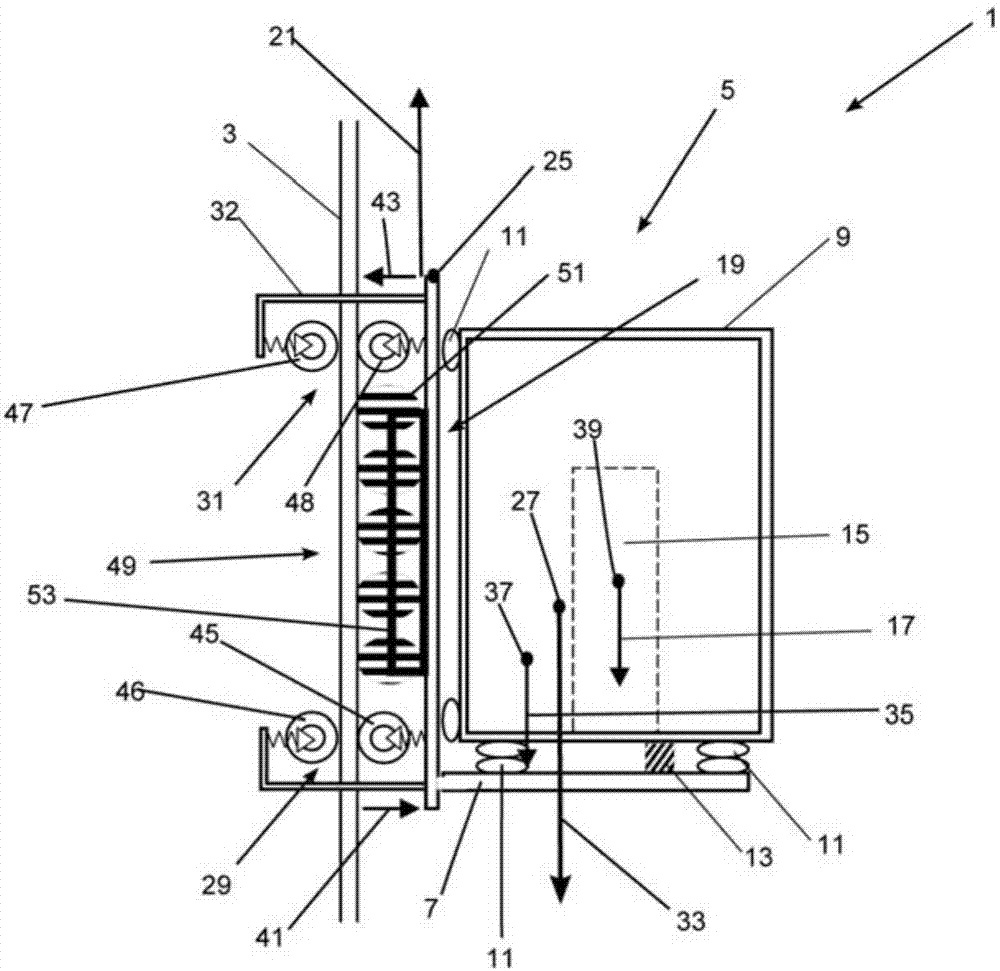

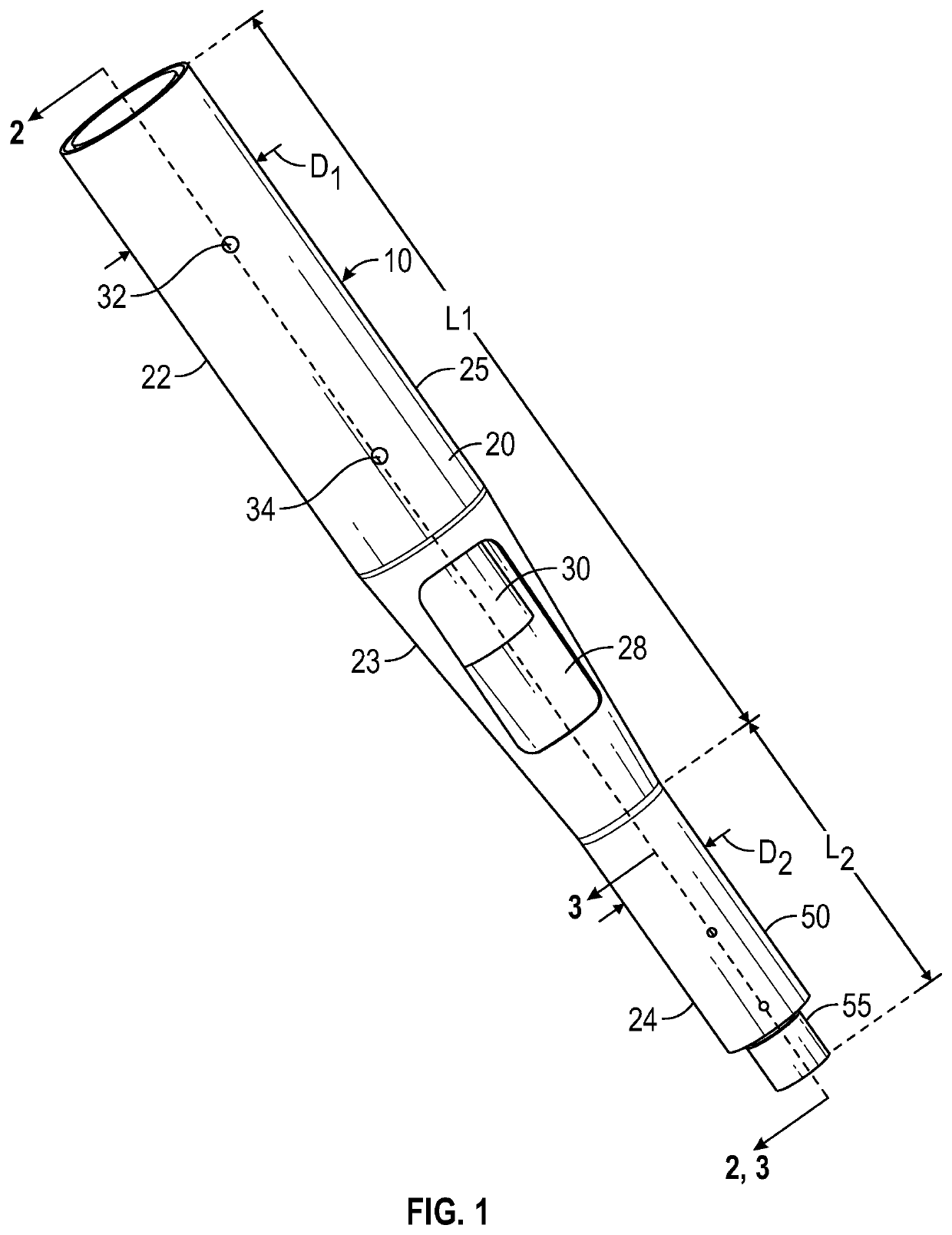

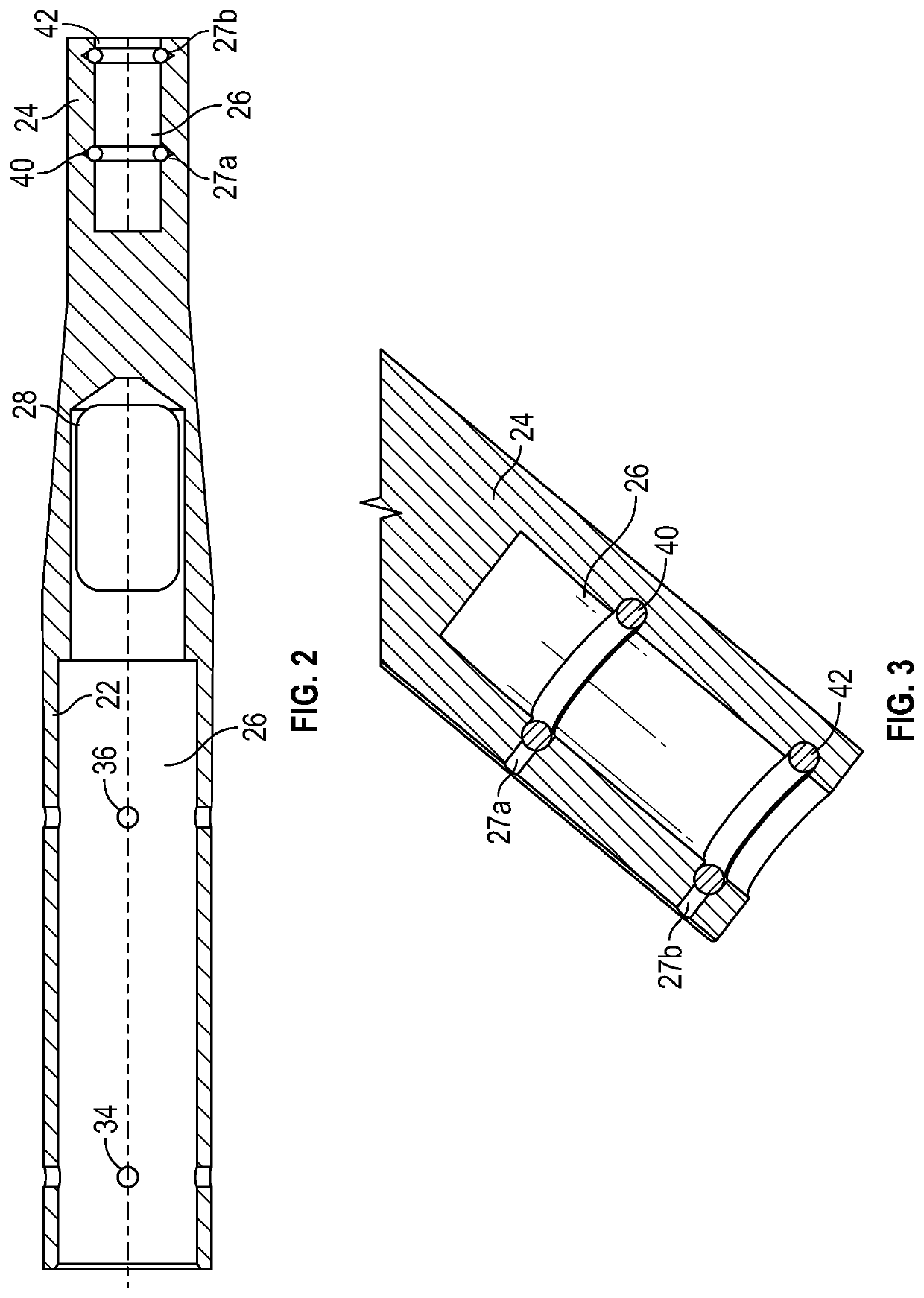

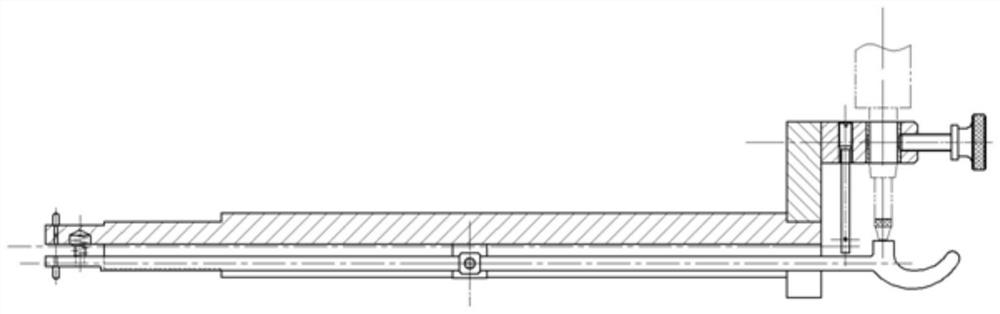

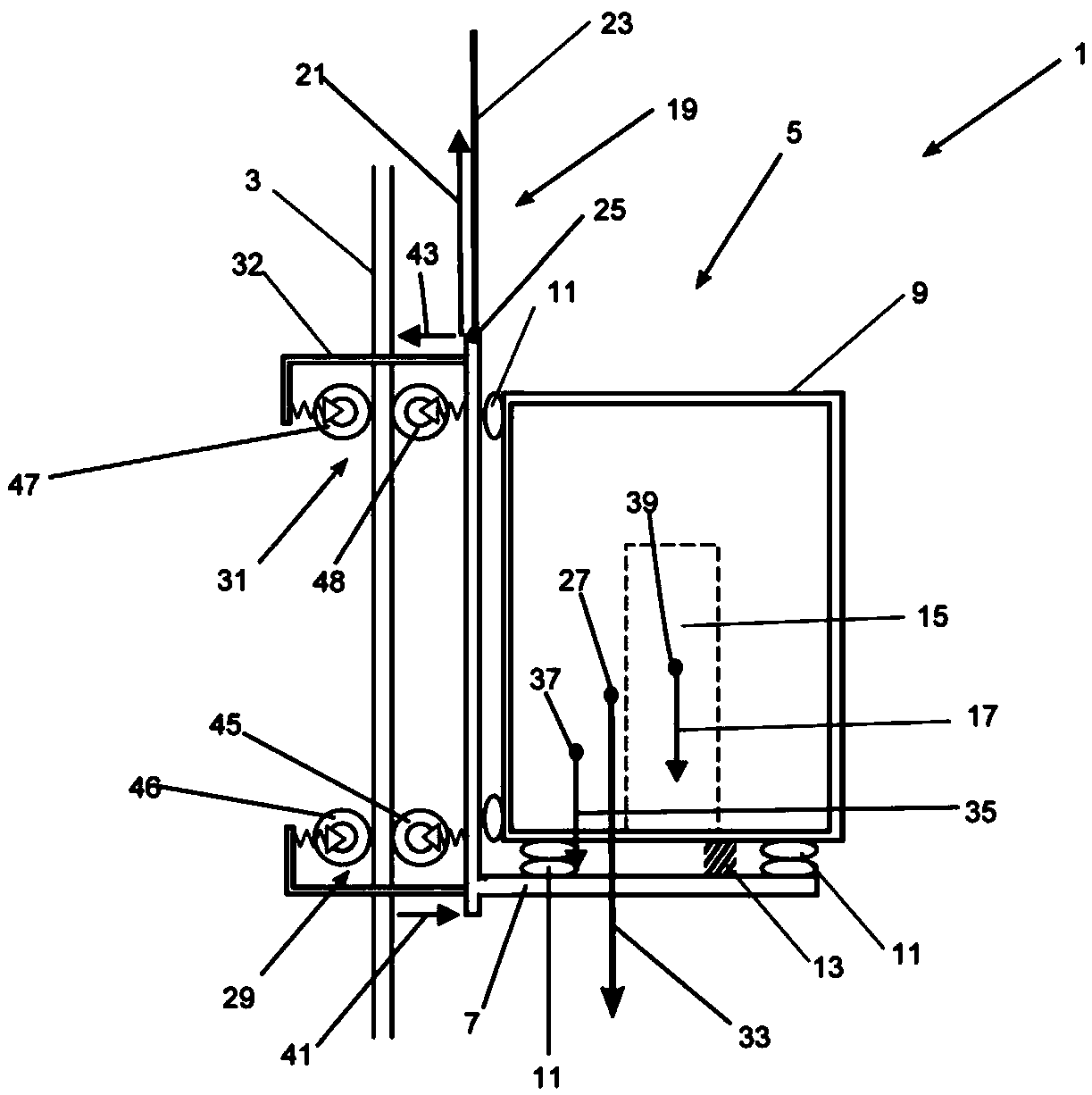

A system for duplicating a master key includes a clamping mechanism for receiving and positioning a master key. The master key defines a major key axis and an intermediate key axis along which a key blade variably extends. The key blade has an upper surface and a minor key axis along a key thickness. A mechanical measurement device includes a probe that deflects along the intermediate key axis during a measurement process. A movement mechanism imparts relative motion along the major key axis between the mechanical measurement device and the master key. The mechanical probe follows the upper surface of the key blade. The mechanical measurement device generates a signal indicative of the deflection of the probe. A processor receives the signal and generates information usable for defining the machining of a duplicate key.

Owner:THE HILLMAN GRP INC

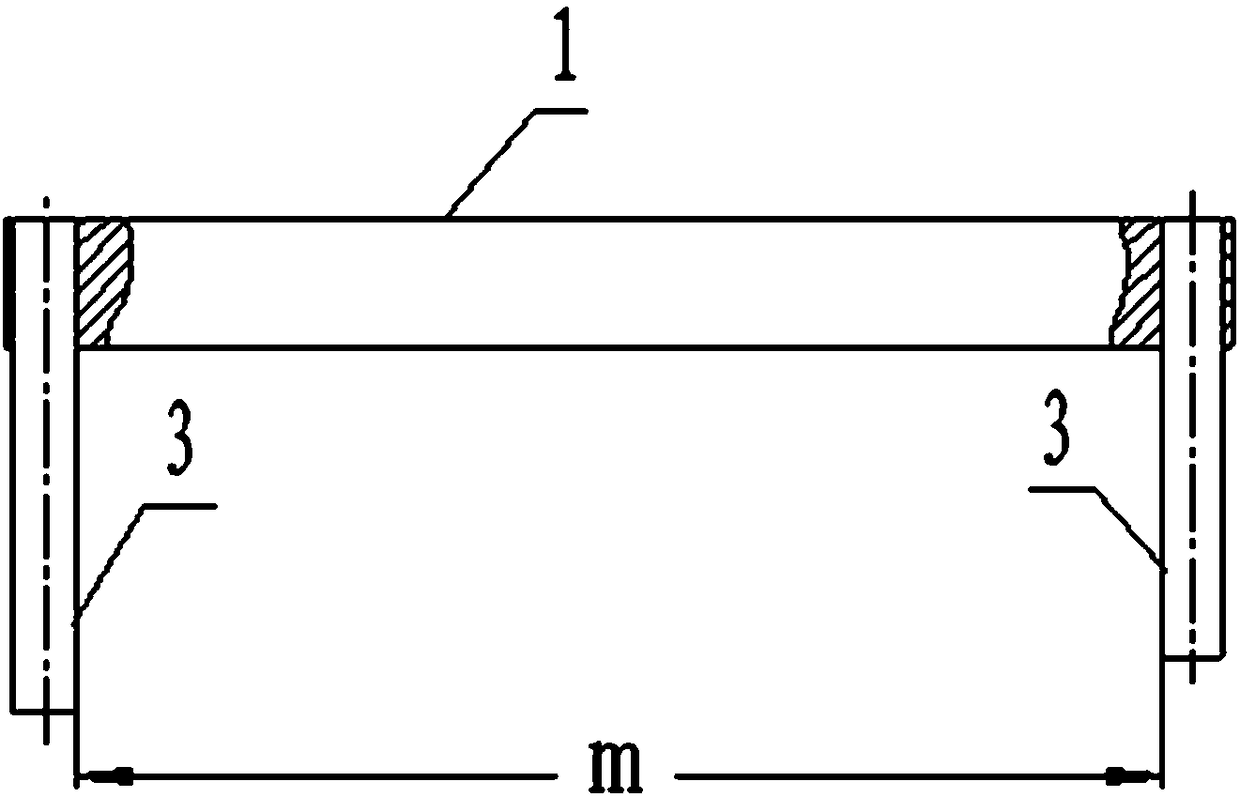

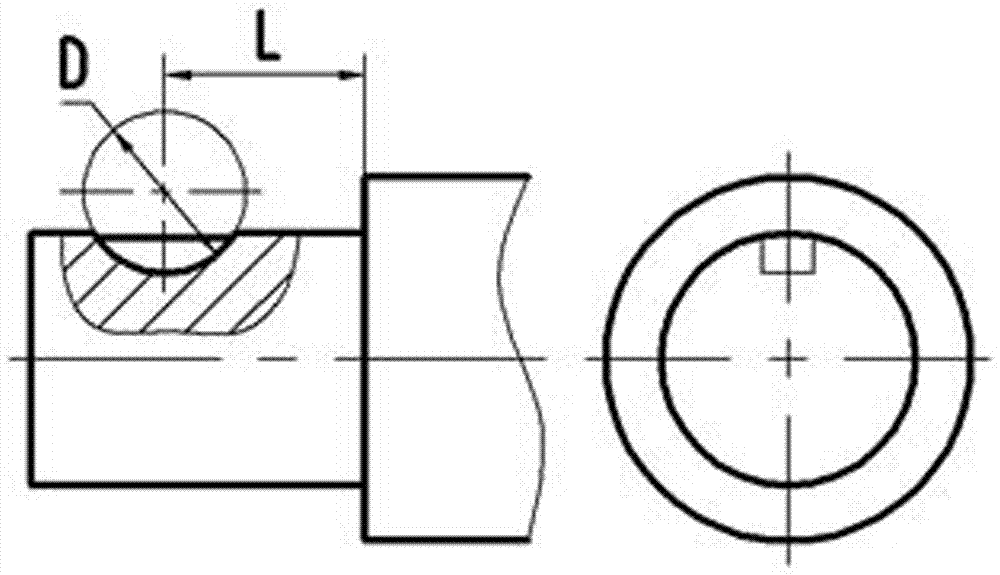

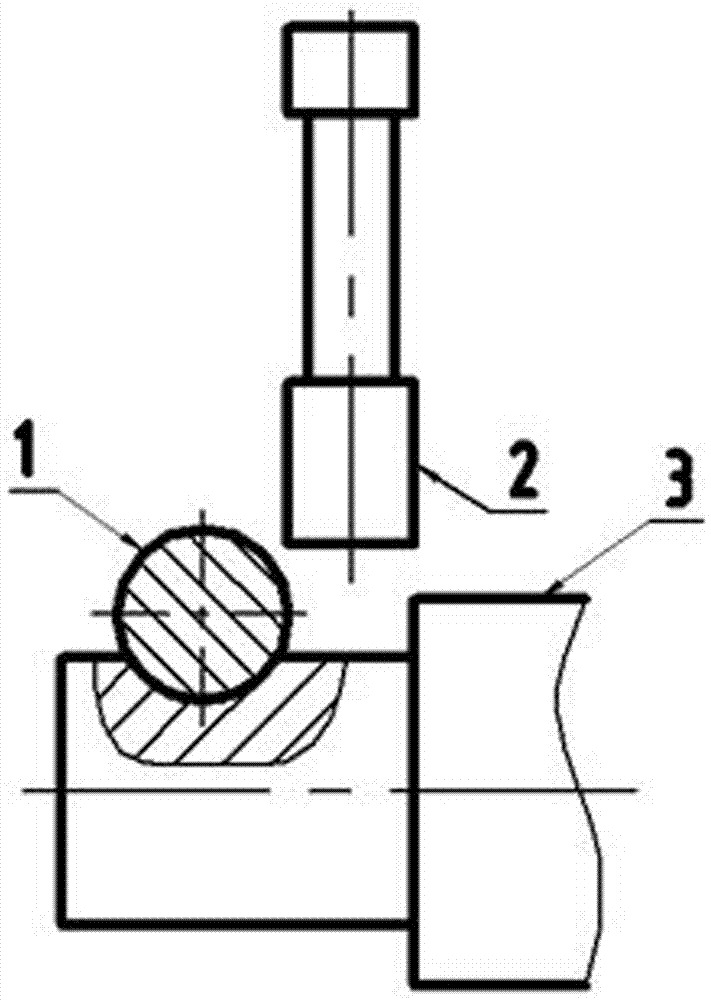

Gauge for measuring maximum and minimum values of intervals between rods of internal spline on part

PendingCN108692642AEasy to measureEasy to manufactureMechanical clearance measurementsKey-ways measurementsEngineering

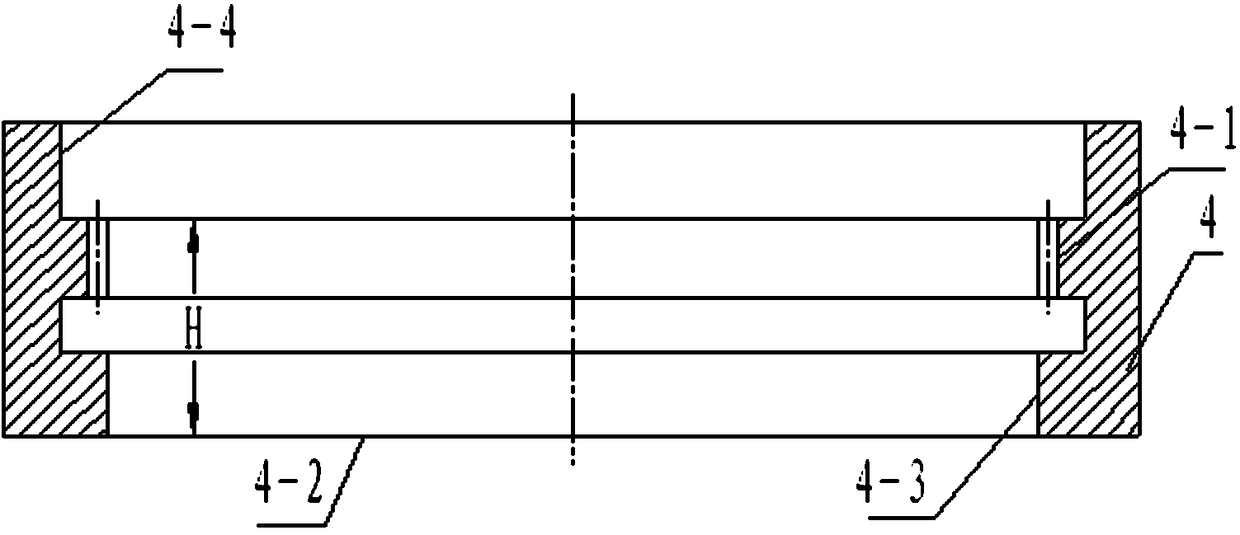

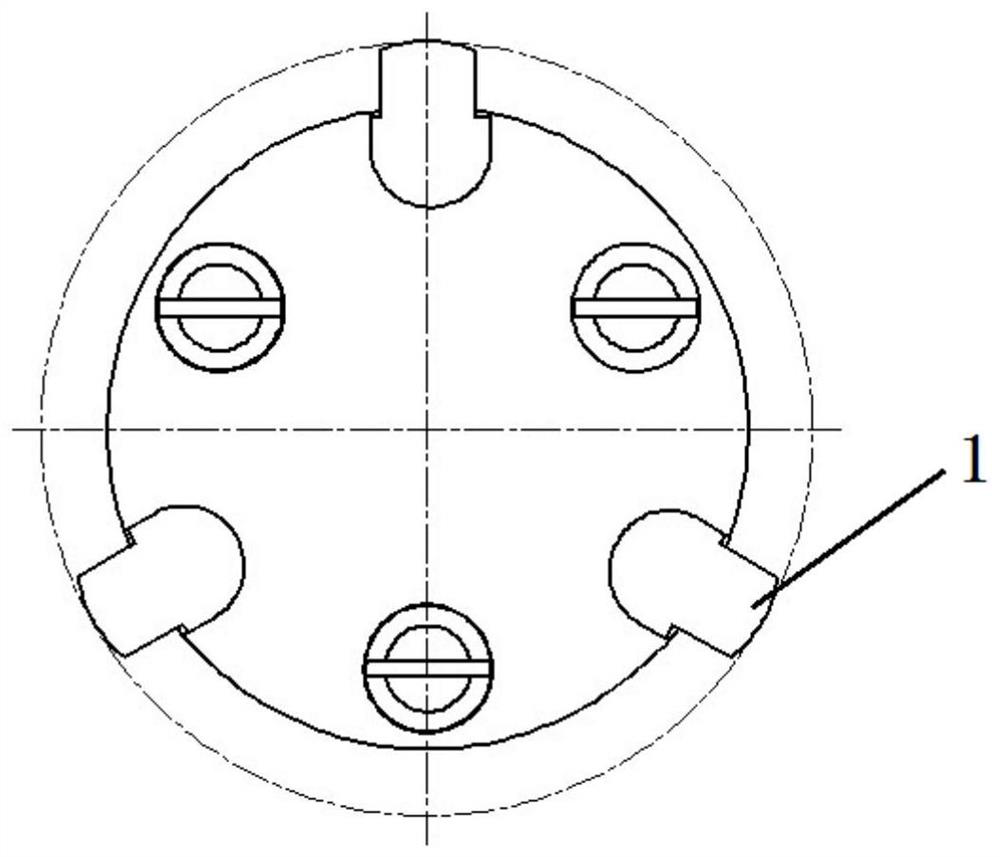

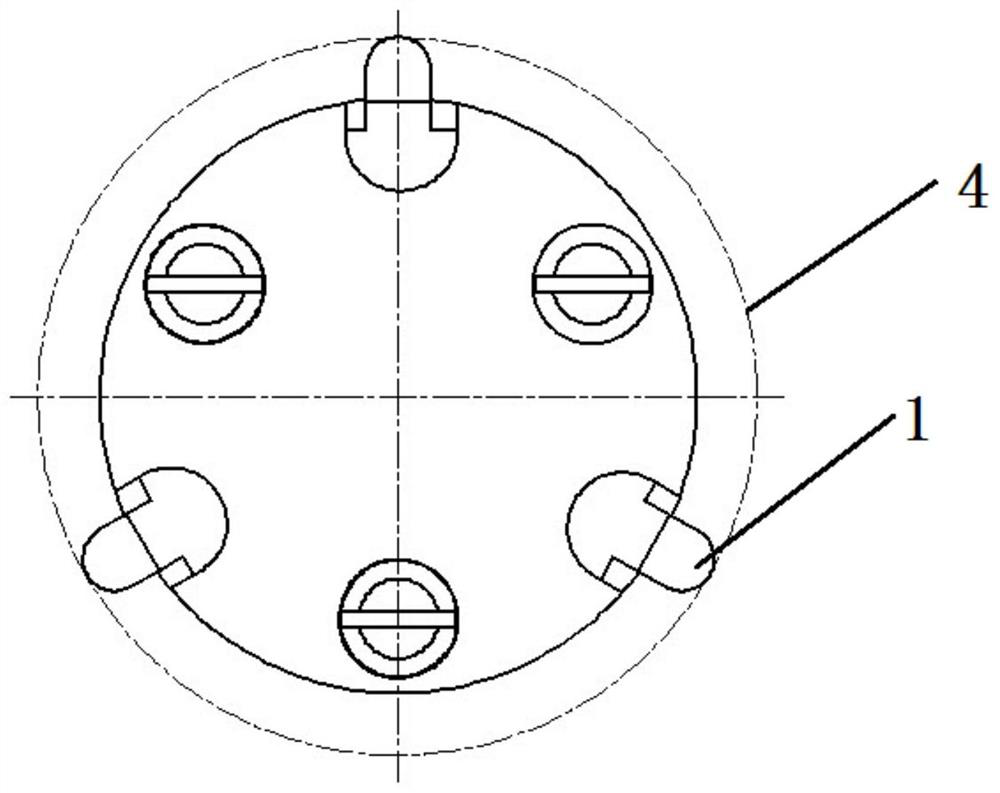

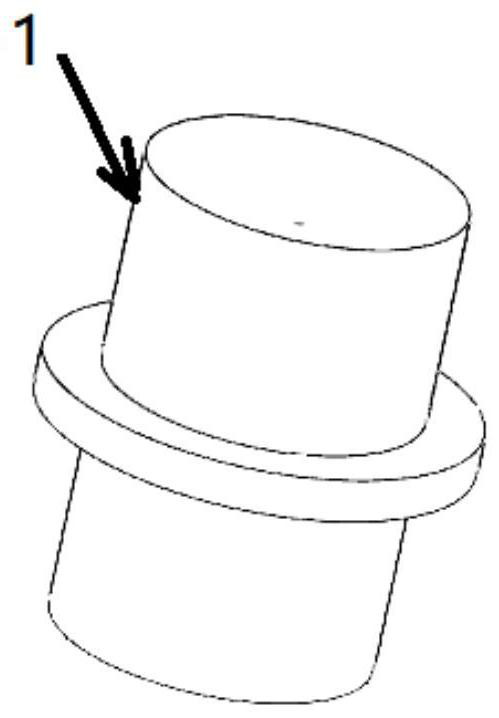

The invention provides a gauge for measuring the maximum and minimum values of intervals between rods of an internal spline on a part, wherein the gauge is easy for manufacturing and measurement and is higher in efficiency. According to the gauge, the internal spline is a small-modulus involute odd-tooth internal spline, and the gauge is of a split structure. A big gauge column comprises a cylinder I with the height I, wherein the height of the cylinder I is corresponding to the height from the upper end face of the internal spline to the lower end face of the part, and the diameter I of the cylinder = (the maximum value of intervals between rods + the diameter of gauge rods) / cos(90 degrees / the number of teeth of the internal spline) - the diameter of the gauge rods. The diameters of threegauge rods are corresponding to the widths of tooth slots of the internal spline. The cylinder I of the big gauge column is located in the part. Two gauge rods are located in any two tooth slots which are located in a 45-degree (central angle) range of one side of the internal spline, and one gauge rod is inserted into any one tooth slot which is located in a 45-degree (central angle) range of the other side of the internal spline, wherein the above two 45-degree (central angle) ranges are symmetric at the center of the small-modulus involute odd-tooth internal spline.

Owner:CHONGQING WANGJIANG IND

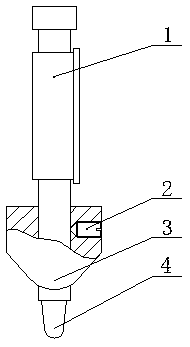

Tool for deciphering the depths or cuts on a key from the lock itself

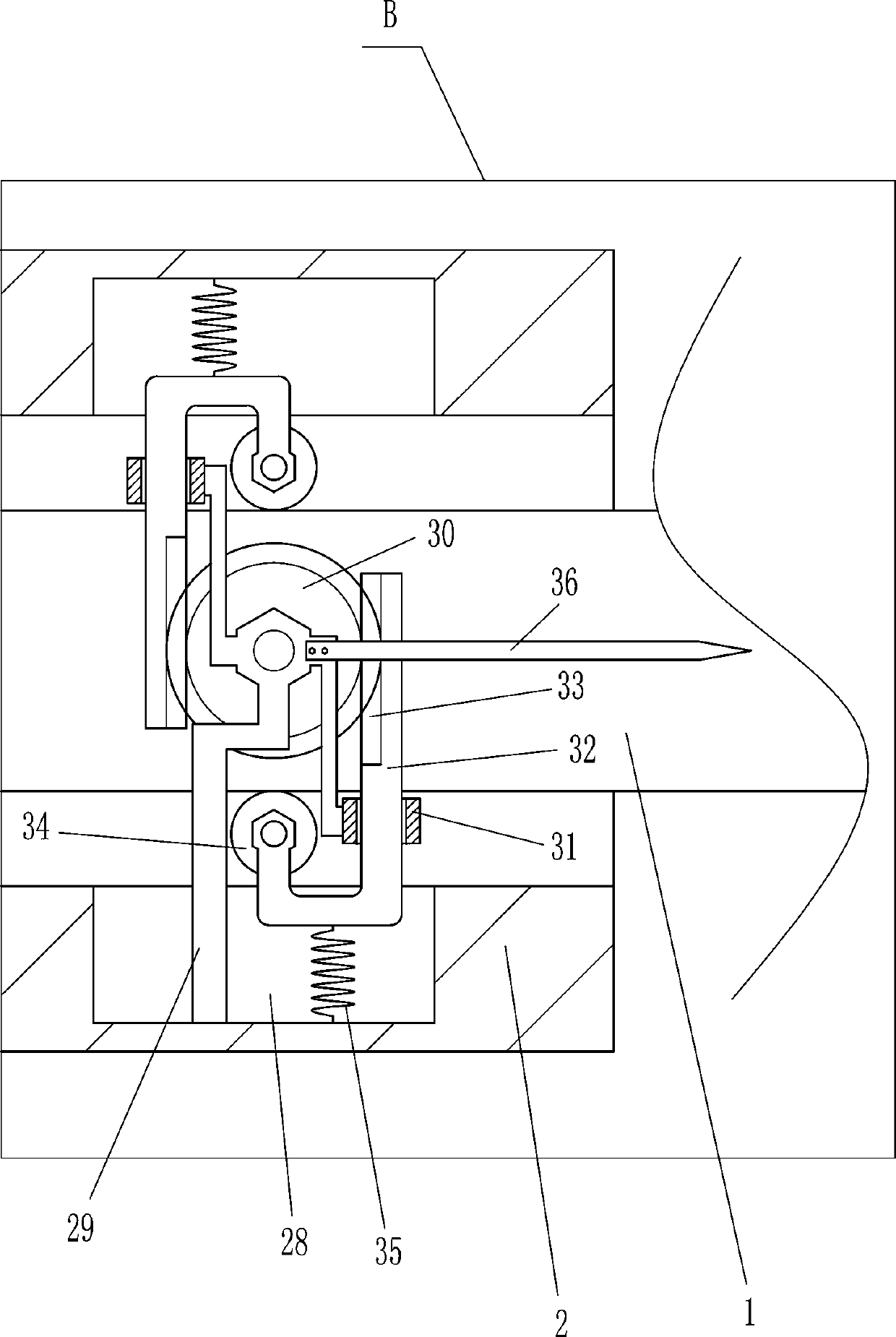

The objective of the invention is to allow the user to decipher the cuts (aka. depths) on a key from the lock without disassembling the lock. The current wafer lock readers on the market rely on a sensitive touch to operate and / or do not give the exact depths to recreate a key. Our wafer lock “reader” will give the exact depth of a cut, coming to a definite stop at the reading position for each cut on the key.

Owner:CAPEHART KEITH DANIEL

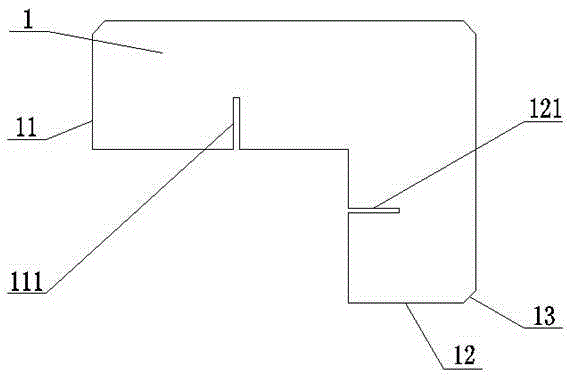

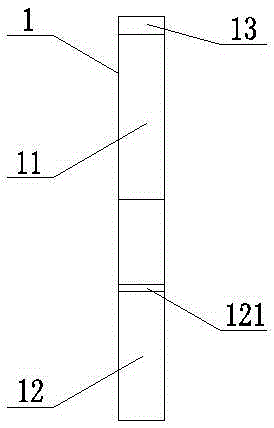

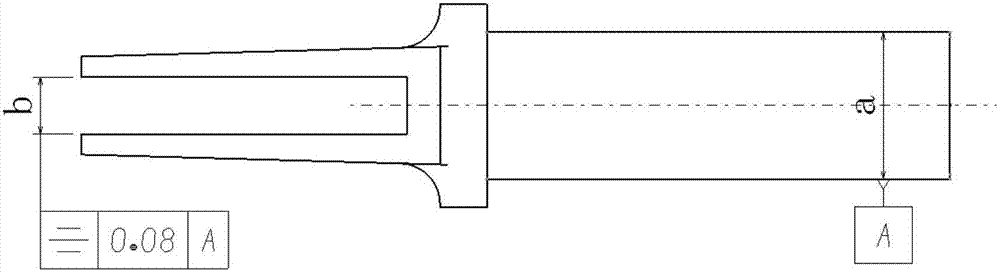

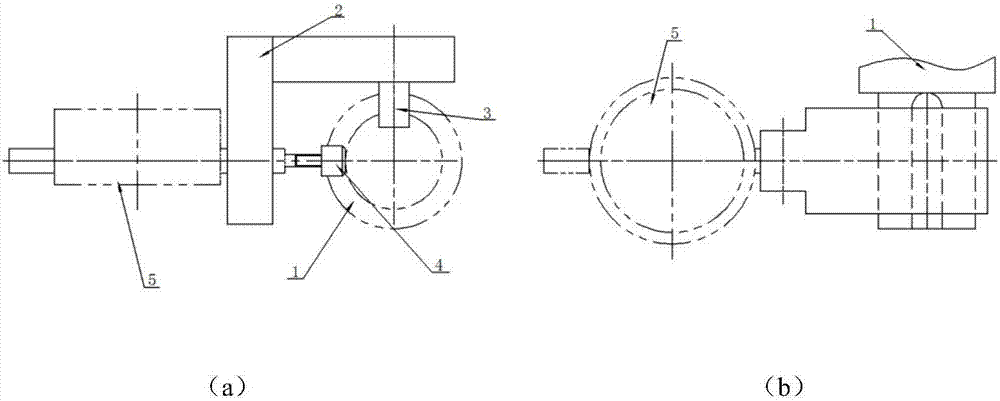

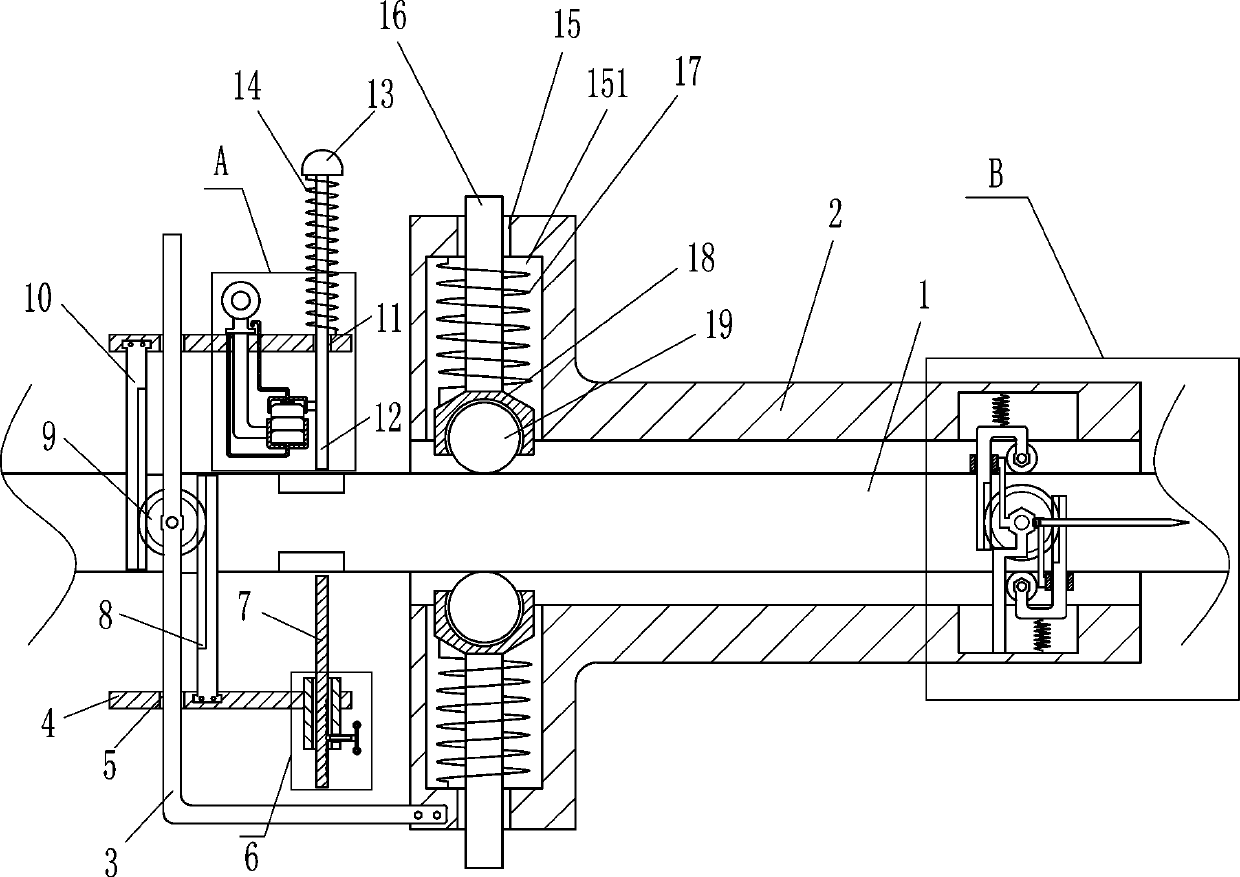

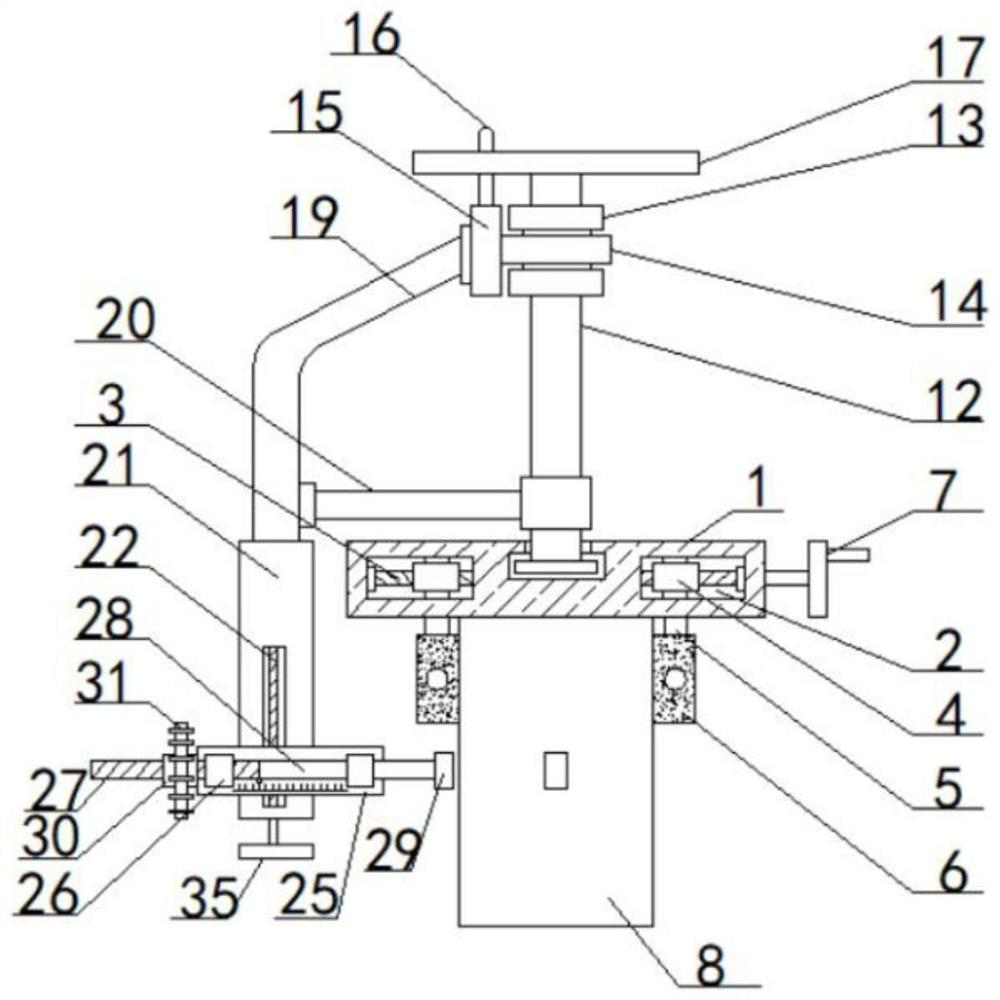

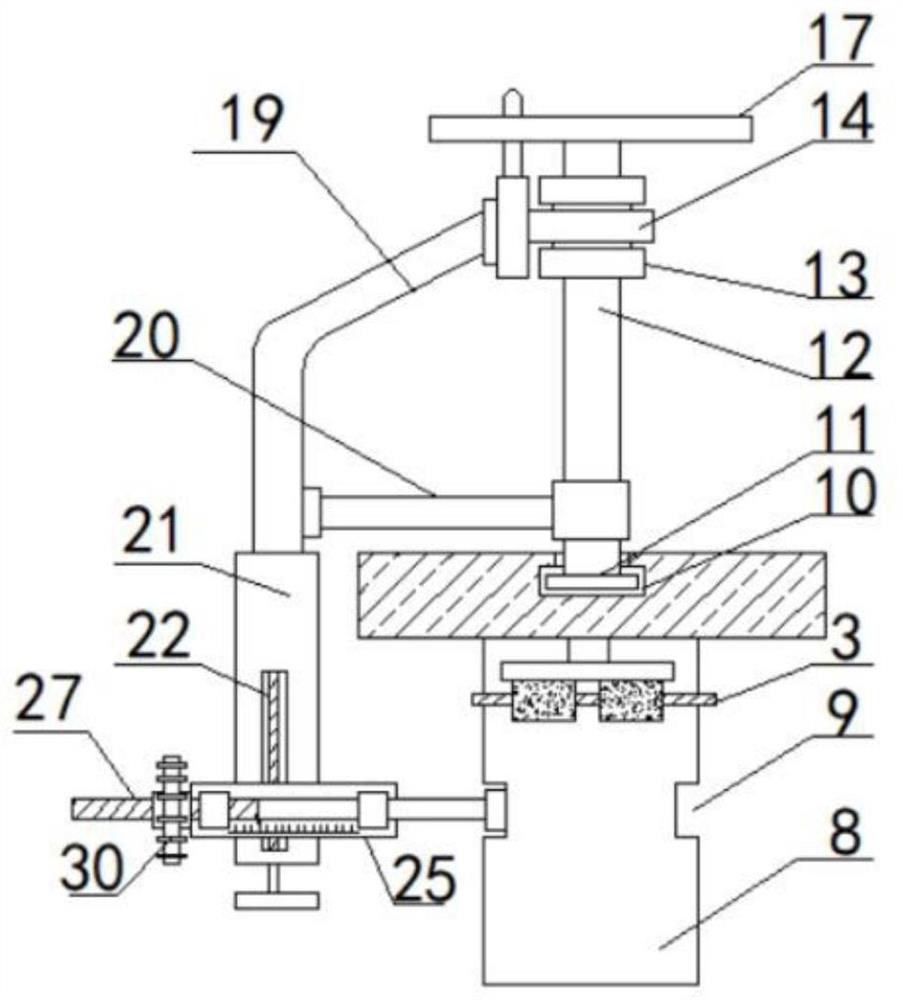

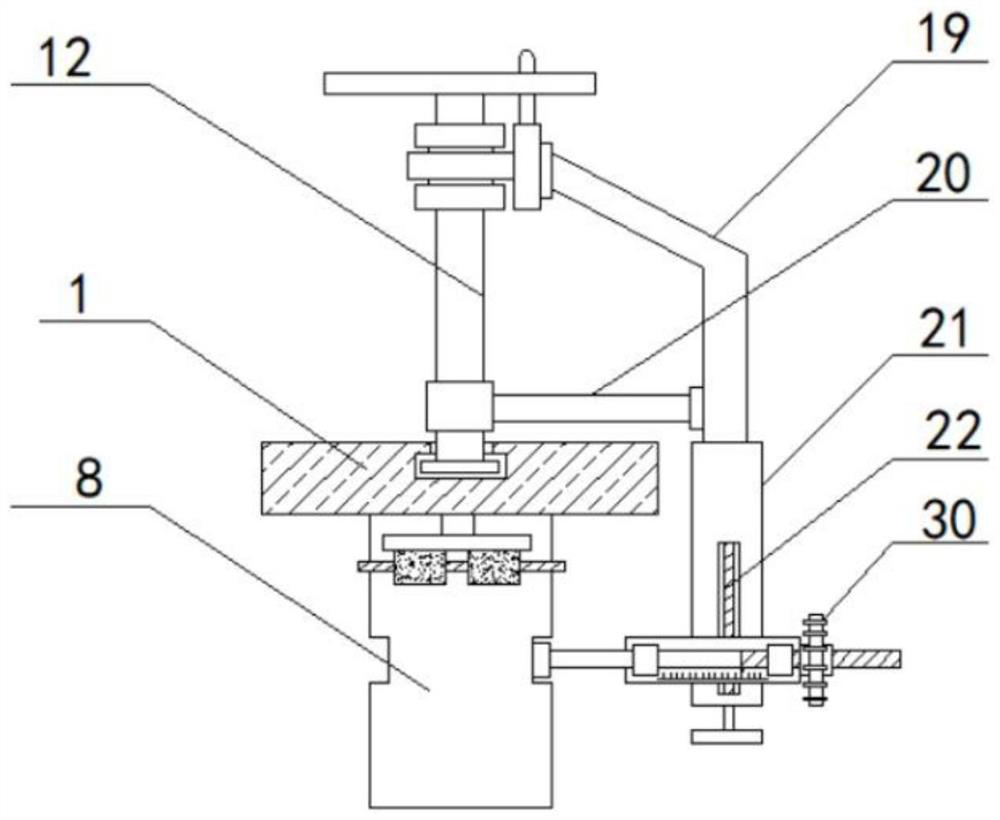

Special measuring tool for measuring symmetry degree of shaft part key groove

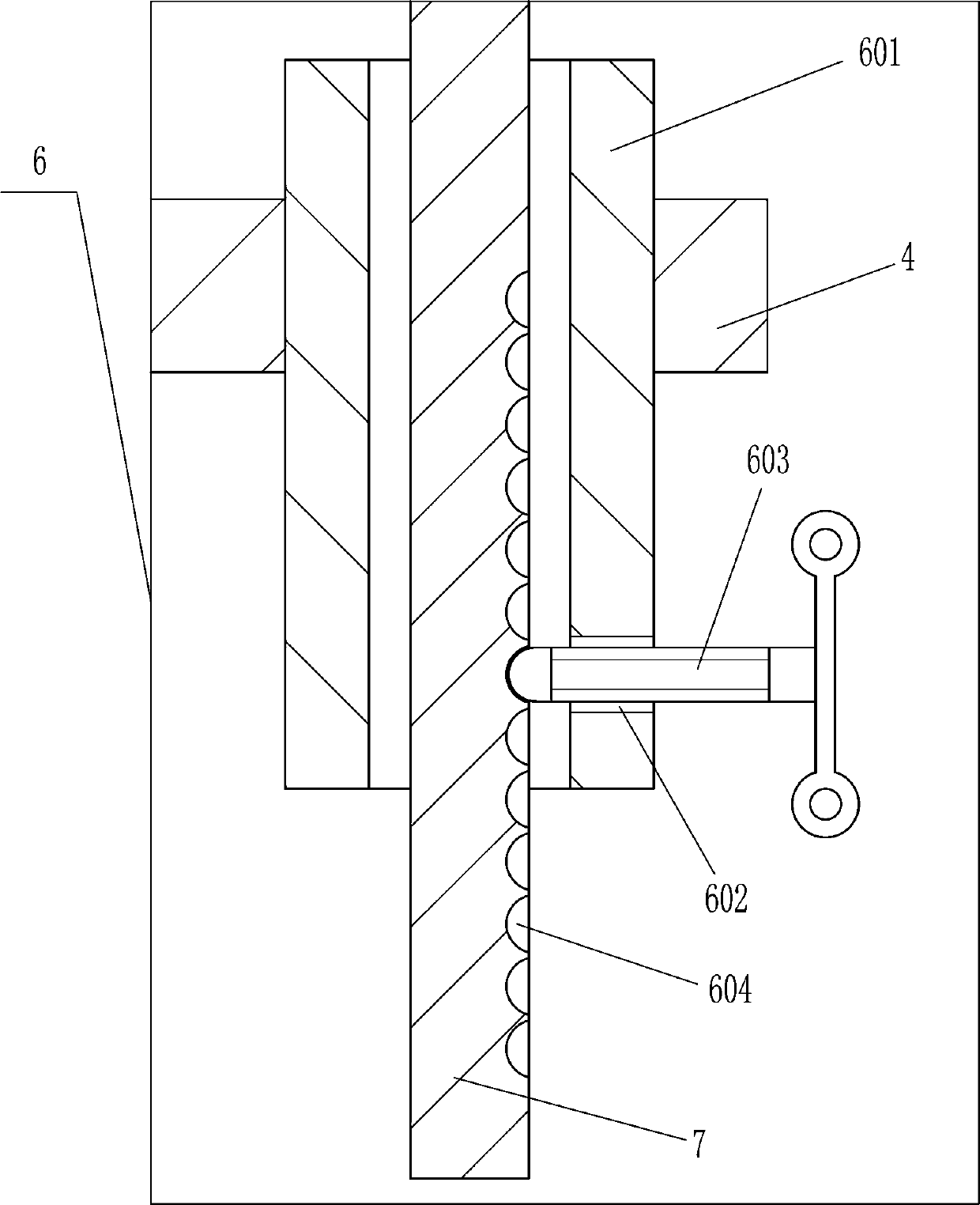

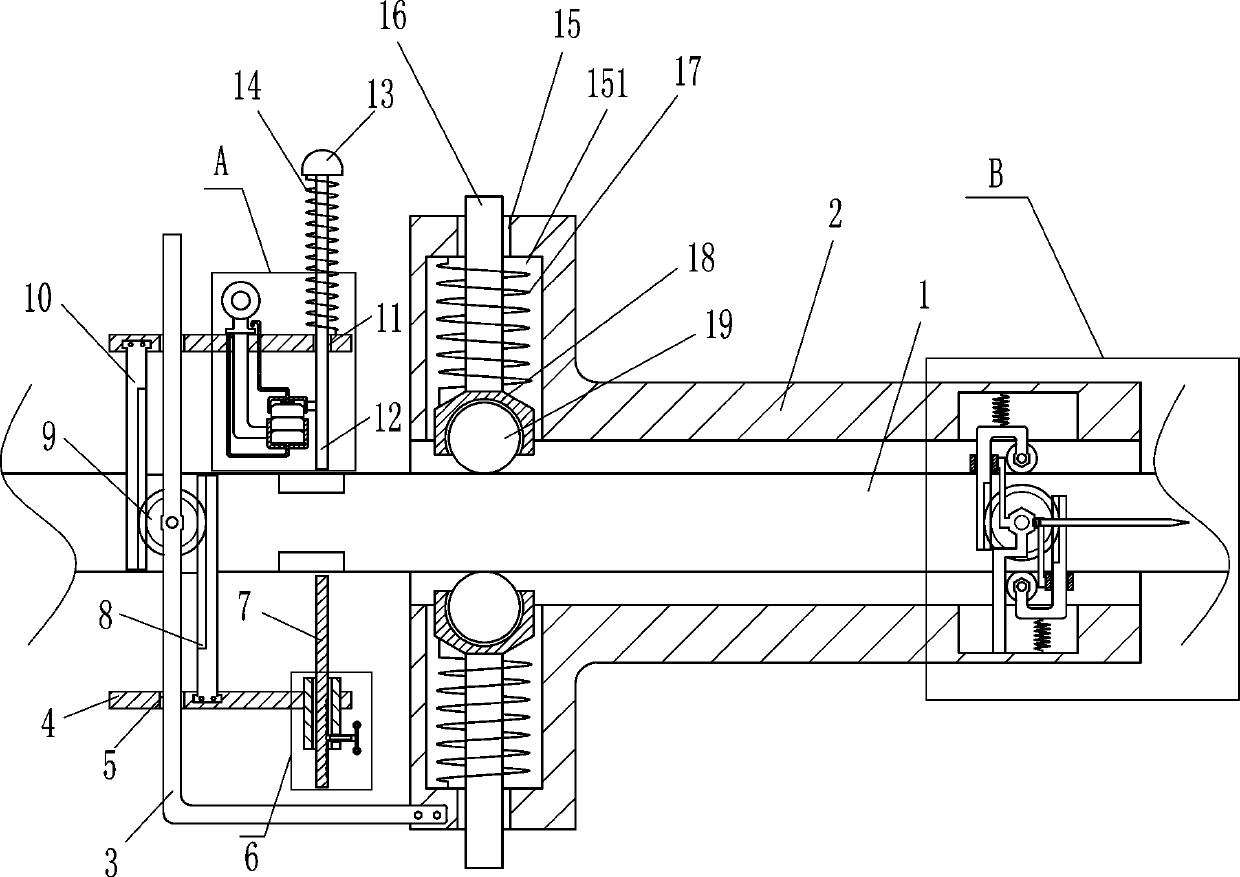

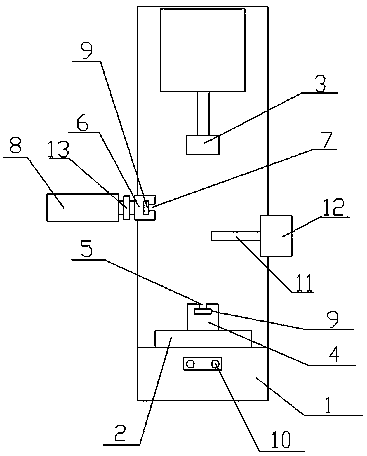

InactiveCN109682288AKnow asymmetryEasy to moveAngles/taper measurementsKey-ways measurementsEngineeringHand pain

The invention relates to a special measuring tool, in particular to a special measuring tool for measuring the symmetry degree of a shaft part key groove and solve the technical problem that people can measure the symmetry degree of the shaft part key groove conveniently, a manual ruler is not needed, and the phenomenon that the efficiency is affected by hand pain is avoided. The technical schemeof the special measuring tool for measuring the symmetry degree of the shaft part key groove comprises a hollow handle, a first support bar, a support plate, an adjusting device, a first measuring rodand the like; the first support rod is fixedly connected to the lower part of the left side of the front side of the hollow handle, and a first gear is rotationally arranged at the upper part of therear side of the first support rod. According to the special measuring tool for measuring the symmetry degree of the shaft part key groove, under the action of the first measuring rod and the second measuring rod, a press block is pushed, the first measuring rod and the second measuring rod can measure the symmetry degree of the shaft part key groove, the manual ruler is not needed to measure theposition length of the key groove to obtain the symmetry degree, the operation is more convenient, and a detection shaft can move more smoothly in the hollow handle under the action of a universal ball.

Owner:JINGGANGSHAN UNIVERSITY

Crankshaft key groove length gauge

ActiveCN105423851AImprove detection efficiencyHigh precisionKey-ways measurementsEngineeringCrankshaft

The invention discloses a crankshaft key groove length gauge, comprising a key groove detection block, wherein a key groove tail measuring block and a key groove head measuring block are arranged on the key groove detection block, a key groove tail measuring port is formed in the bottom of the key groove tail measuring block, a key groove head measuring port is formed on the left side of the key groove head measuring block, and the key groove detection block is provided with chamfers. The crankshaft key groove length gauge is scientific and reasonable in structure and convenient to use; through the measuring ports in the key groove measuring blocks, whether a crankshaft key groove is qualified or not can be conveniently detected, and the crankshaft key groove detection efficiency is improved; through scales on the key groove measuring blocks, the crankshaft key groove detection precision is improved, and the crankshaft key groove can be conveniently detected; moreover, the crankshaft key groove block is integrated, so that damage of a measuring gauge is avoided and the practicability of the measuring gauge is improved.

Owner:ZHEJIANG DINGDA PLASTIC

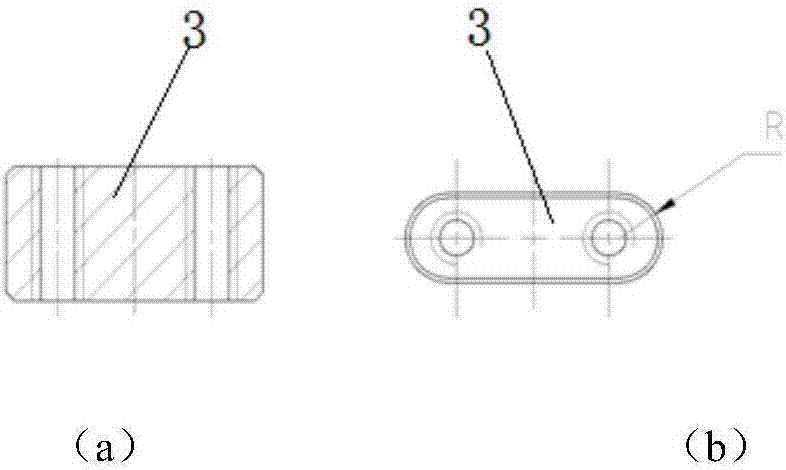

Detection tool and method for measuring axial position size of semicircular key slot of bent shaft

InactiveCN107014273AReduce cost of measurementHigh measurement accuracyKey-ways measurementsKey pressingMeasurement cost

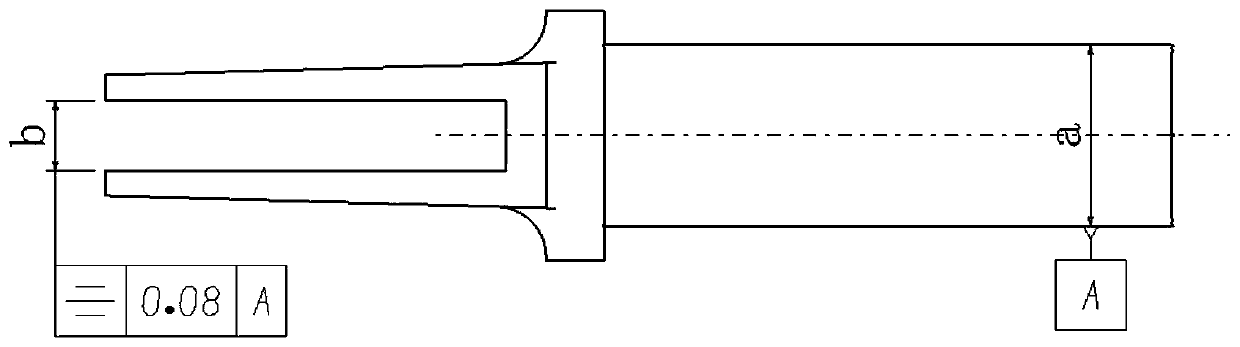

The invention discloses a detection tool and method for measuring the axial position size of a semicircular key slot of a bent shaft. The detection tool comprises a gauge block and a measure gauge, wherein the gauge block is of a flat round shape, the thickness of the gauge block is designed according to the width of the key slot, the round diameter of the gauge block is designed according to the diameter of the inner arc of the key slot, when the gauge block is put into the key slot, an arc of the gauge block is in contact with two sides of the inner arc of the key slot to realize V-shaped positioning, and a central line of the gauge block in the vertical direction overlaps a central line of the inner arc of the key slot; and the measure gauge is a cylinder with a through end and a stop end, the diameters of the through end and the stop end are determined according to the outer diameters of the semicircular key slot, a measurement reference surface and the gauge block, and the gauge block and the measure gauge are matched in use so as to determine whether the size of a detected component from the center of the semicircular key slot to the reference surface meets the drawing requirements. When the technical scheme of the invention is used for measuring the axial position size of the semicircular key slot of the bent shaft, the measurement cost is low, the measurement accuracy is high, an operation method is simple, and the detection efficiency is high.

Owner:桂林福达曲轴有限公司

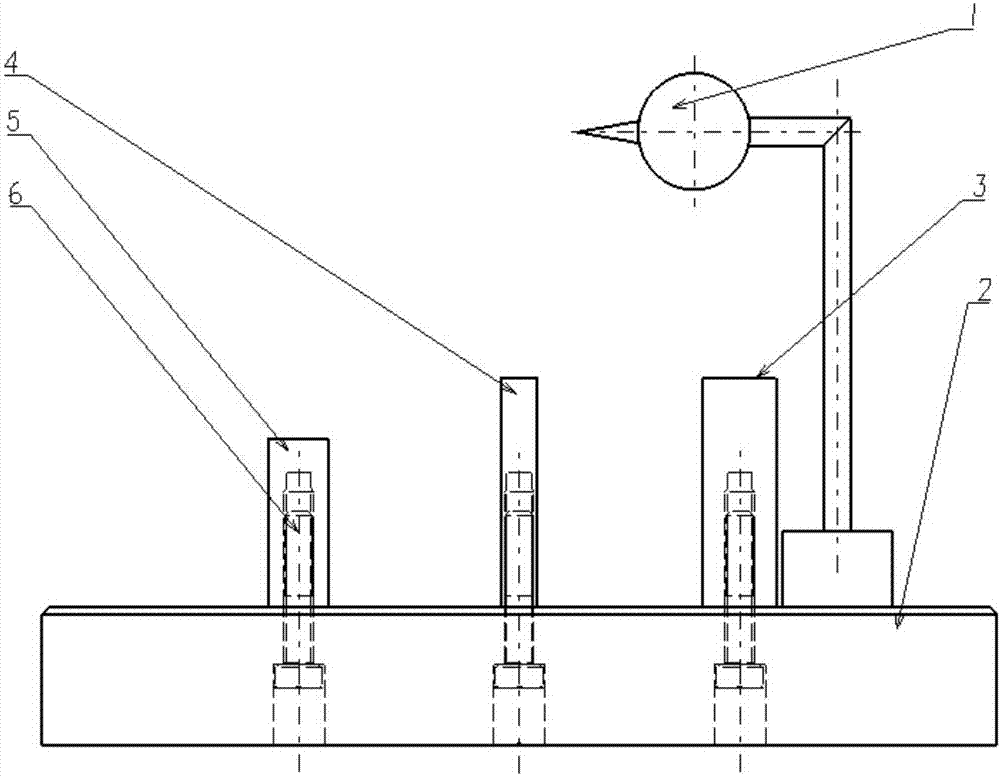

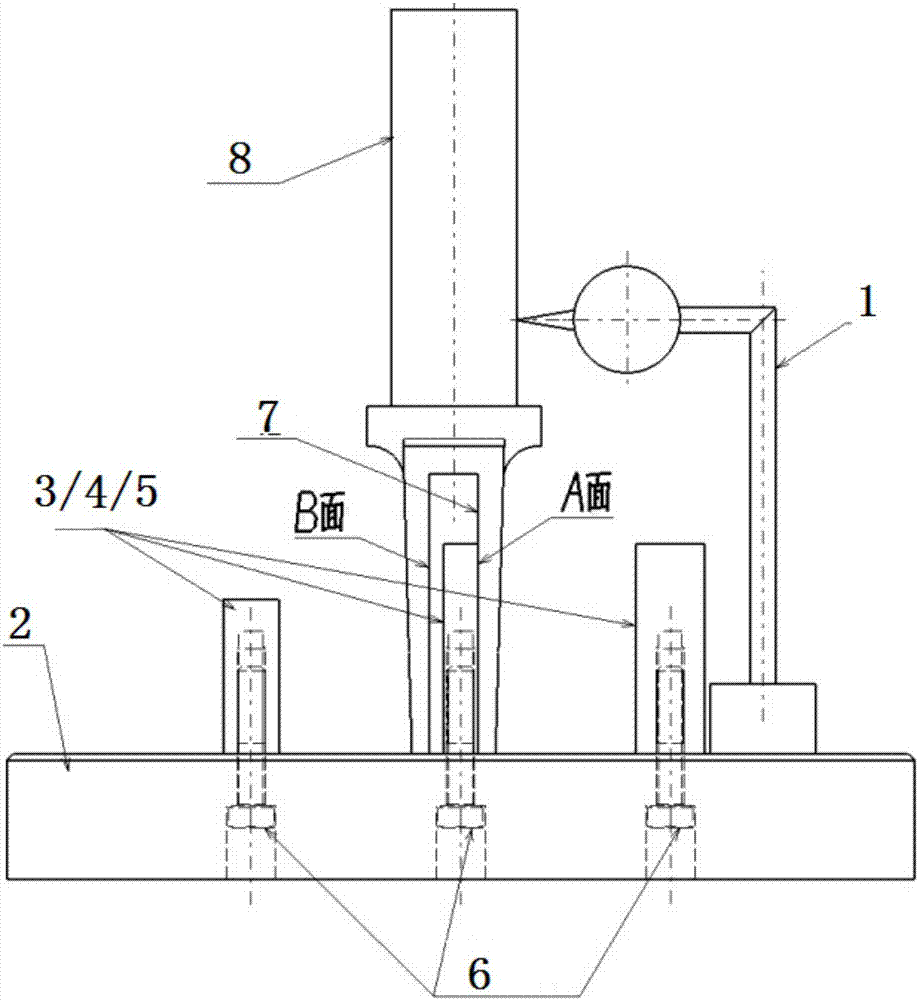

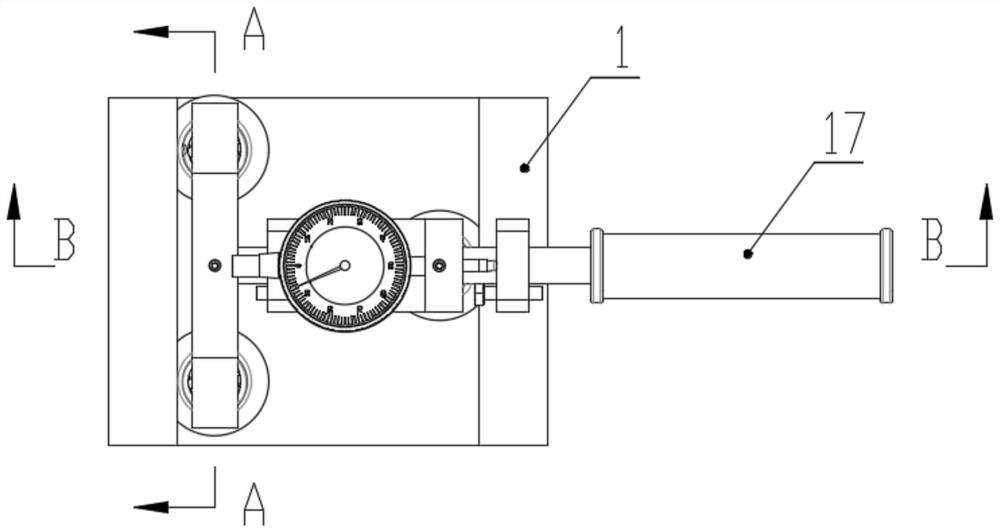

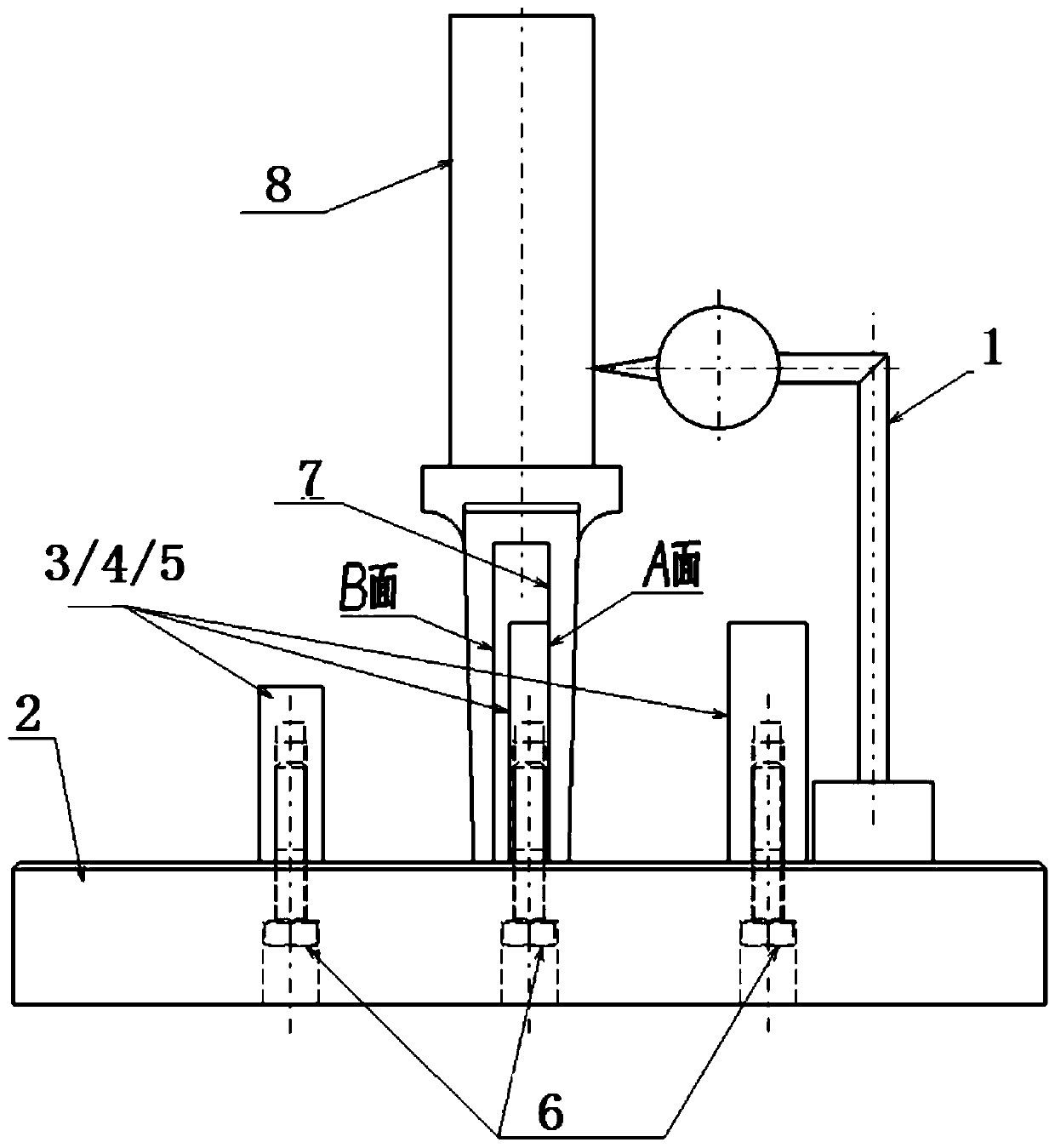

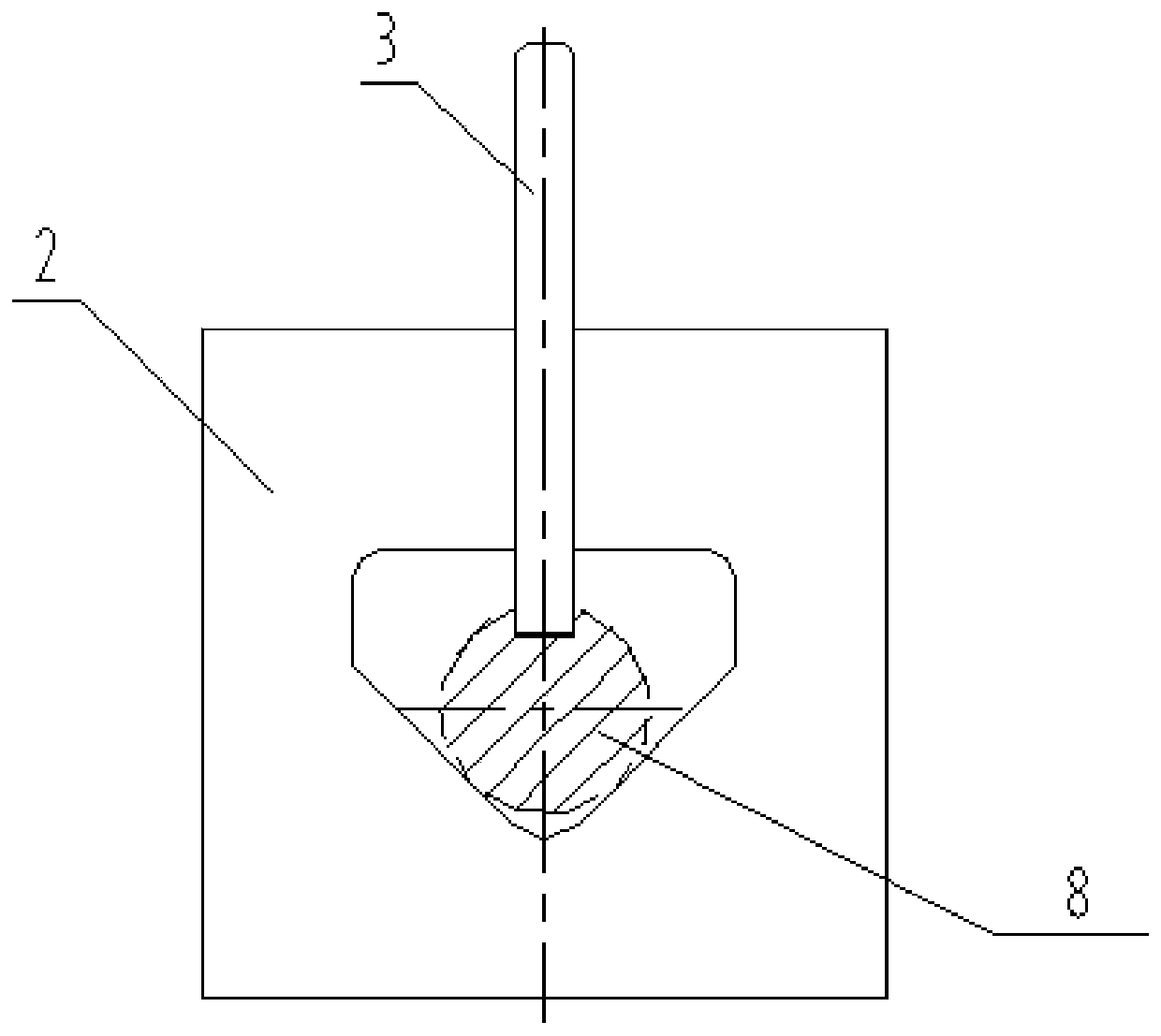

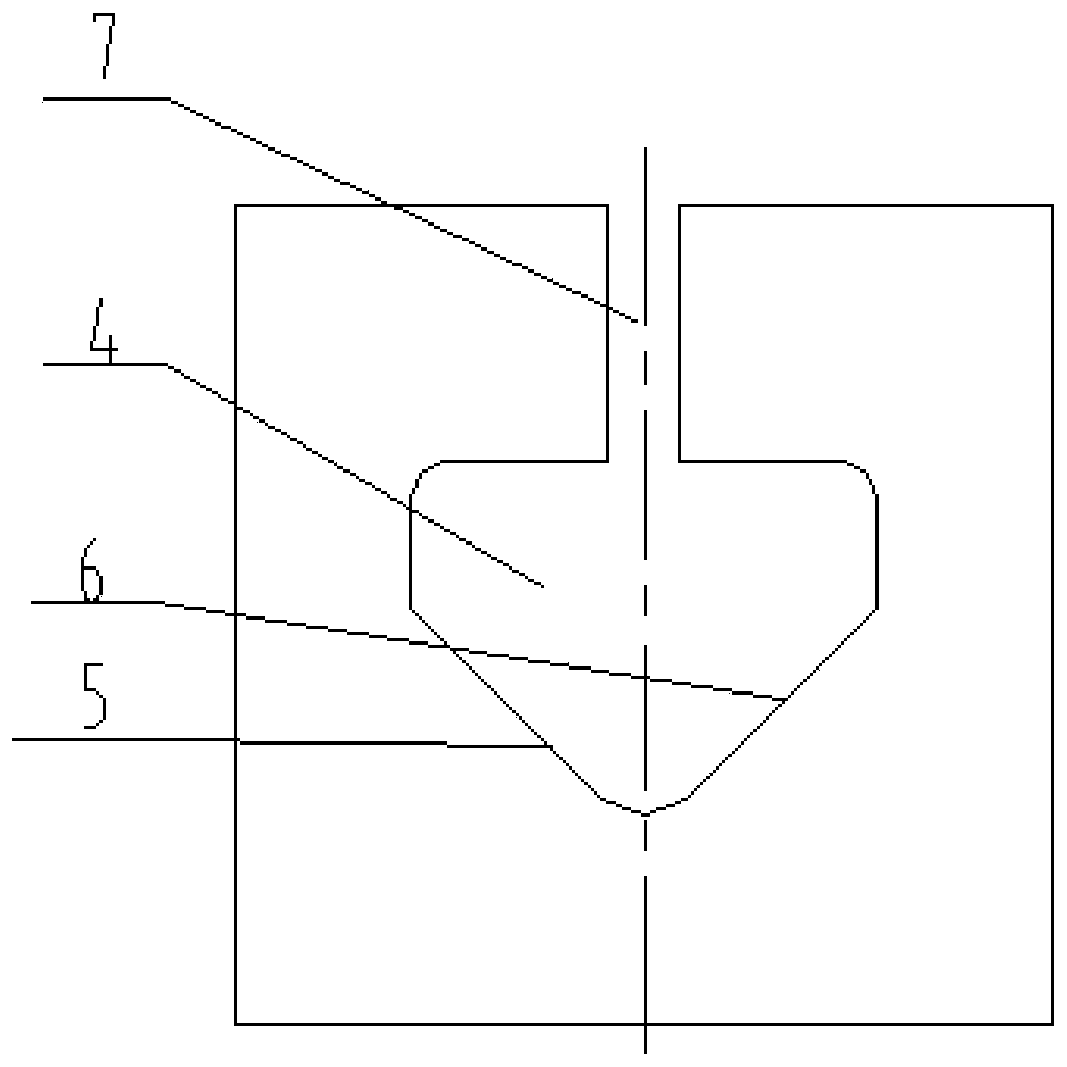

Device and method for measuring symmetry of rudder shaft slot of rudder shaft part

The invention provides a device and a method for measuring the symmetry of a rudder shaft slot of a rudder shaft part. A gauge block I, a gauge block II and a gauge block III are connected side by side above a base through connecting screws. A dial gauge is adsorbed to the base by magnetic force, and is arranged near the gauge block I, the gauge block II or the gauge block III as needed during measurement. The gauge block I, the gauge block II and the gauge block III are set to adapt to rubber shafts with different slot width, and can be disassembled. During measurement, one side in a rudder shaft slot of a rudder shaft part is put close to one gauge block; the contact of the dial gauge contacts the conical surface of the rubber shaft, the rubber shaft is moved along the surface of the gauge block, and the maximum reading of the dial gauge is recorded; the rubber shaft is turned so the other side in the rubber shaft slot is put close to the gauge block; the contact of the dial gauge contacts the conical surface of the rubber shaft, the rubber shaft is moved along the surface of the gauge block, and the maximum reading of the dial gauge is recorded again; and the absolute value of the difference between the two readings of the dial gauge is the symmetry. The device of the invention has a simple structure and a good application effect. The method of the invention is easy to operate, and costs low.

Owner:CAPITAL AEROSPACE MACHINERY +1

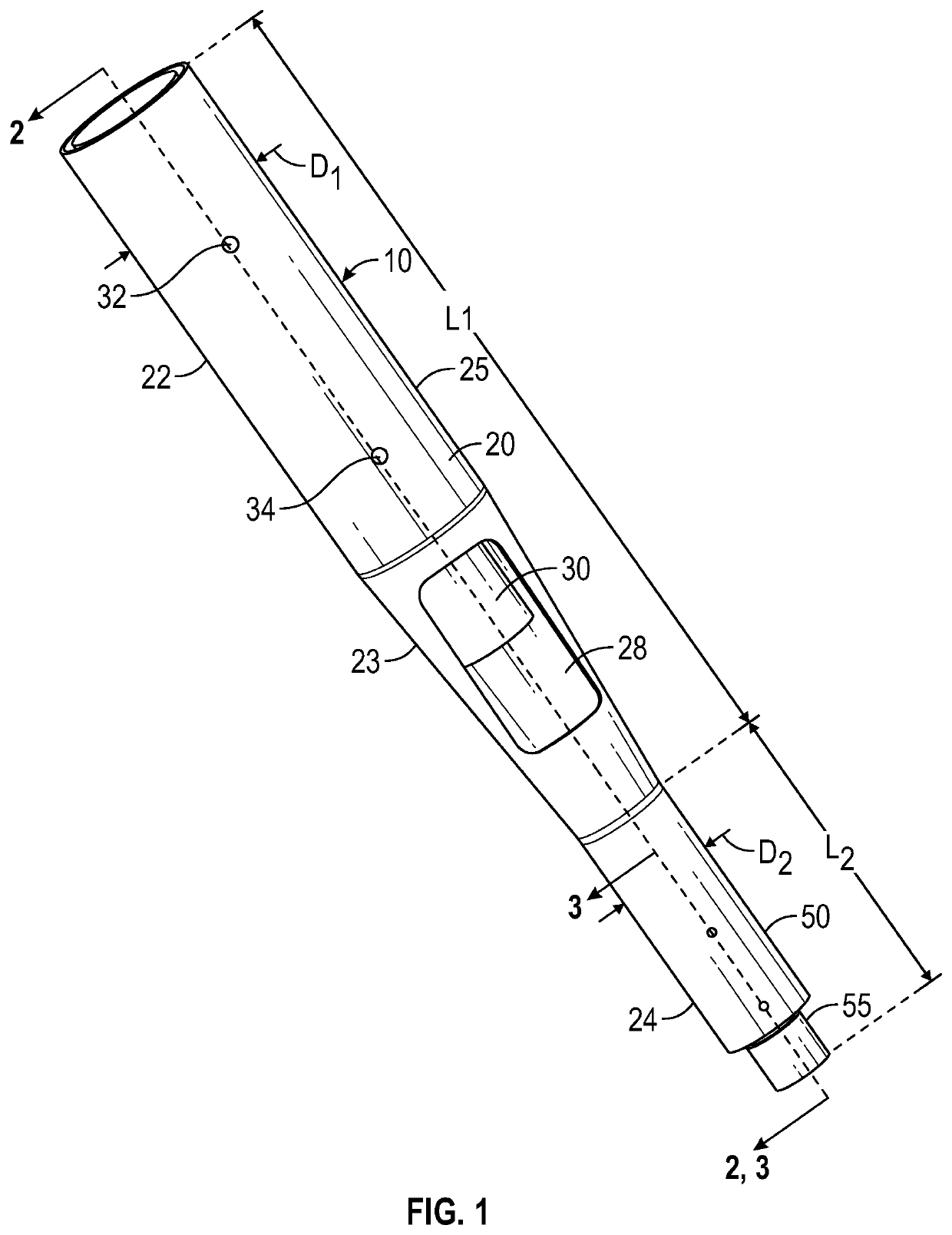

Self-centering mandrel for golf club hosels

ActiveUS11123621B1Reduce variationAccurate measurementUsing optical meansKey-ways measurementsEngineeringErbium lasers

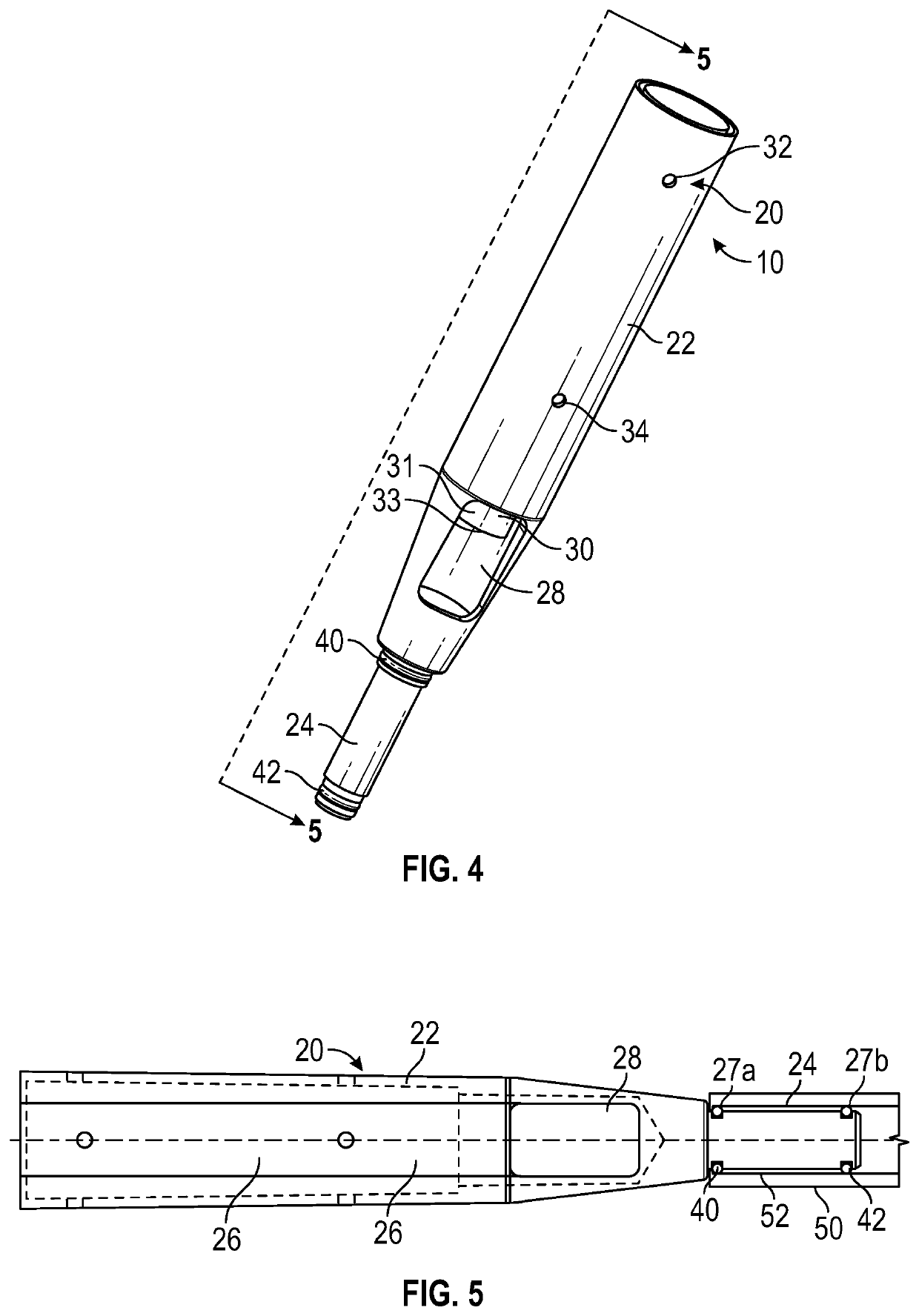

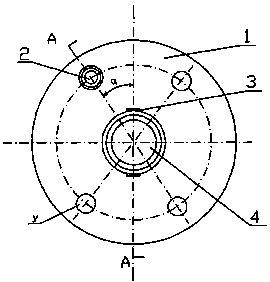

A laser mandrel system that self-centers within a hosel bore of a golf club head to allow for precision adjustment of lie and loft is disclosed herein. The mandrel includes a one-piece housing with upper and lower portions, a laser centered within the upper portion of the housing, and a plurality of o-rings extending around an exterior or interior surface of a lower portion of the housing.

Owner:TOPGOLF CALLAWAY BRANDS CORP

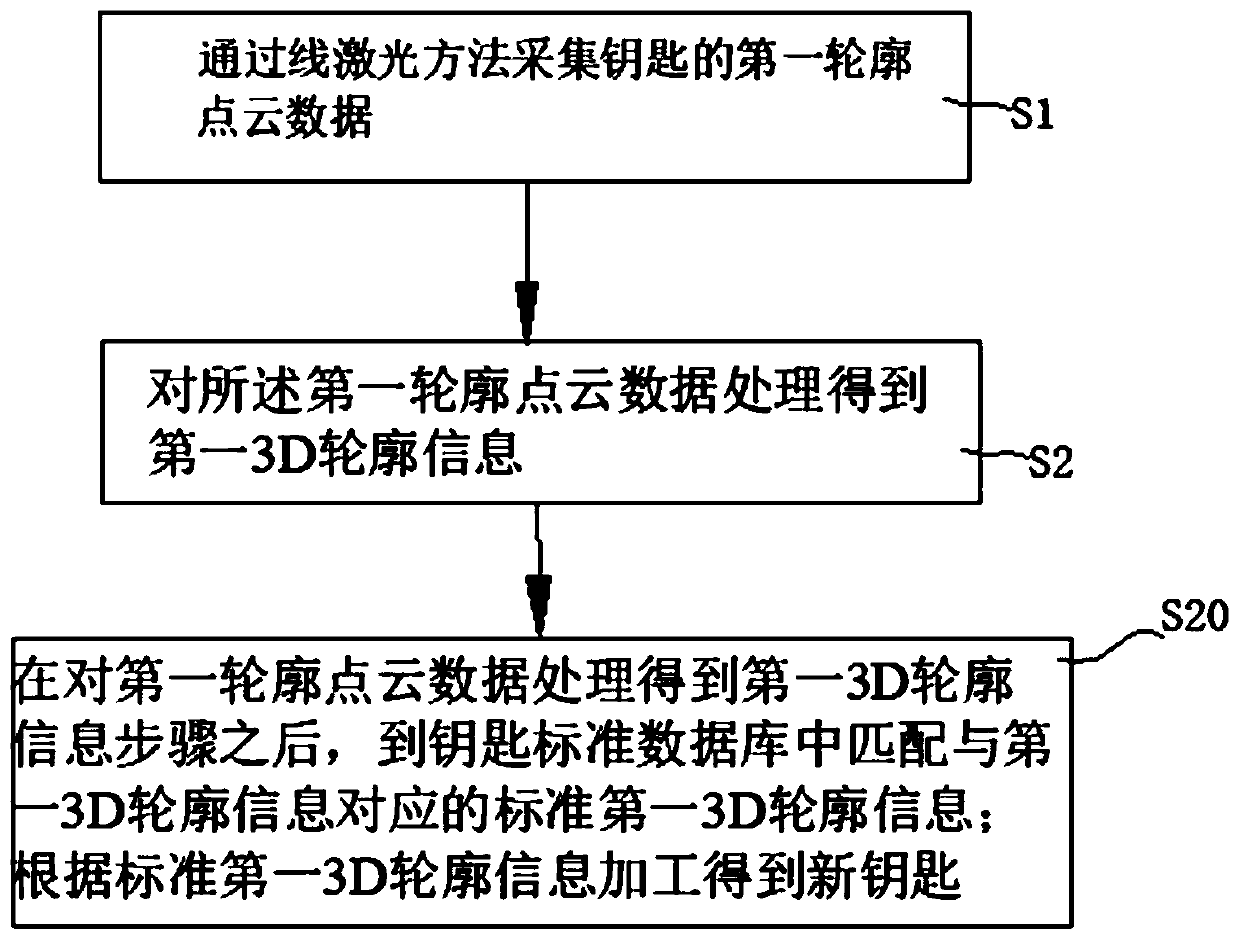

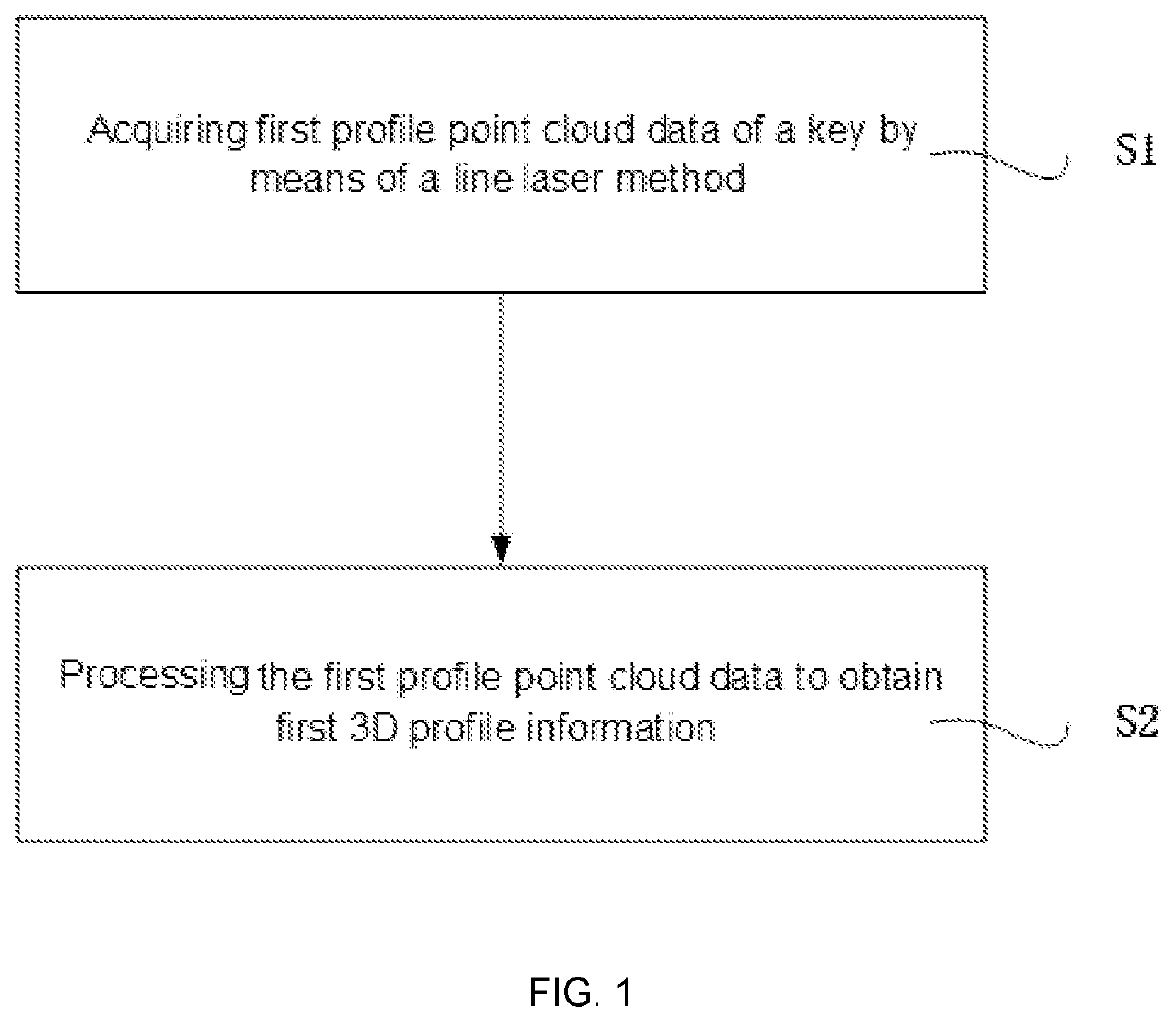

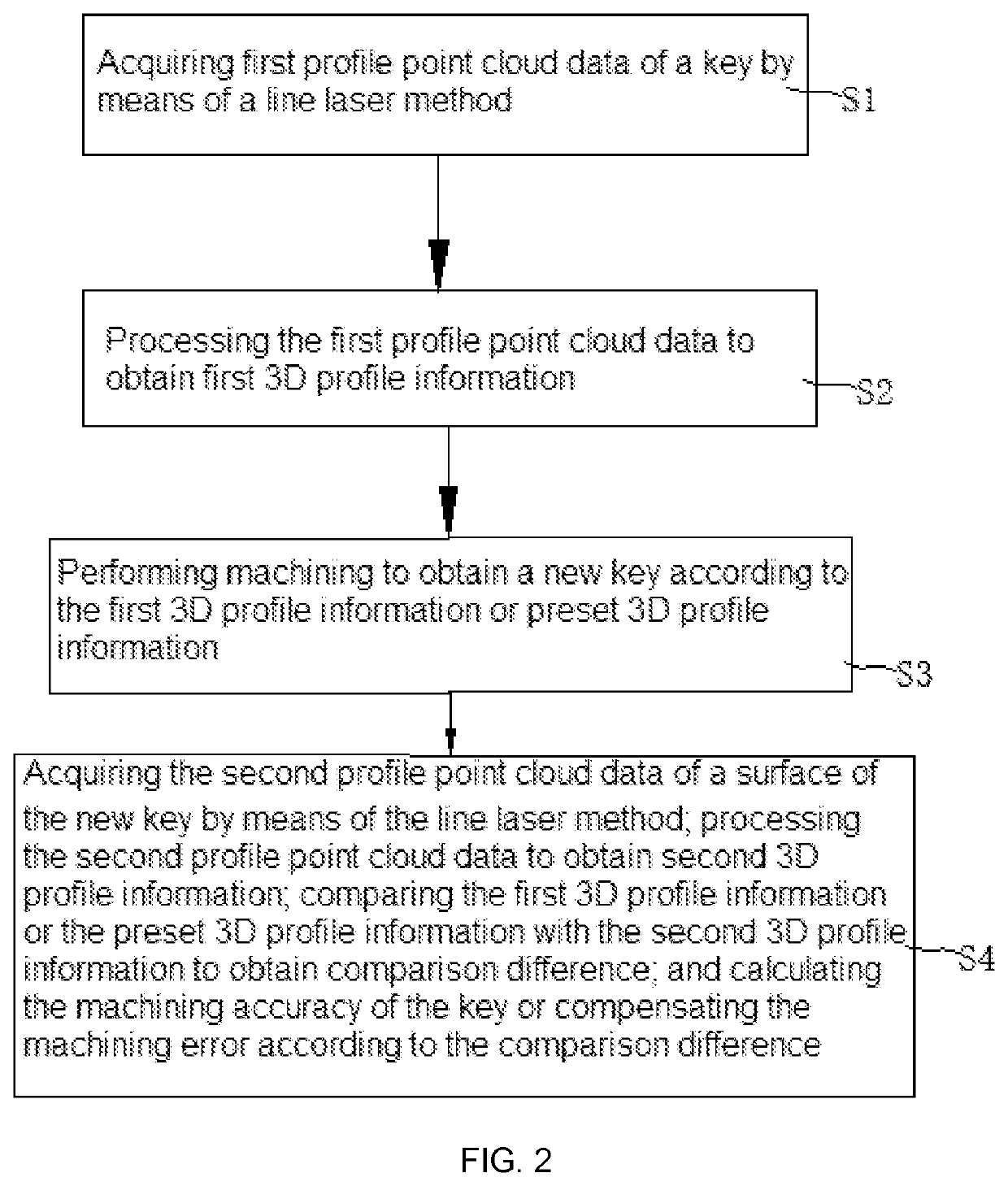

Non-contact key tooth shape learning method and system

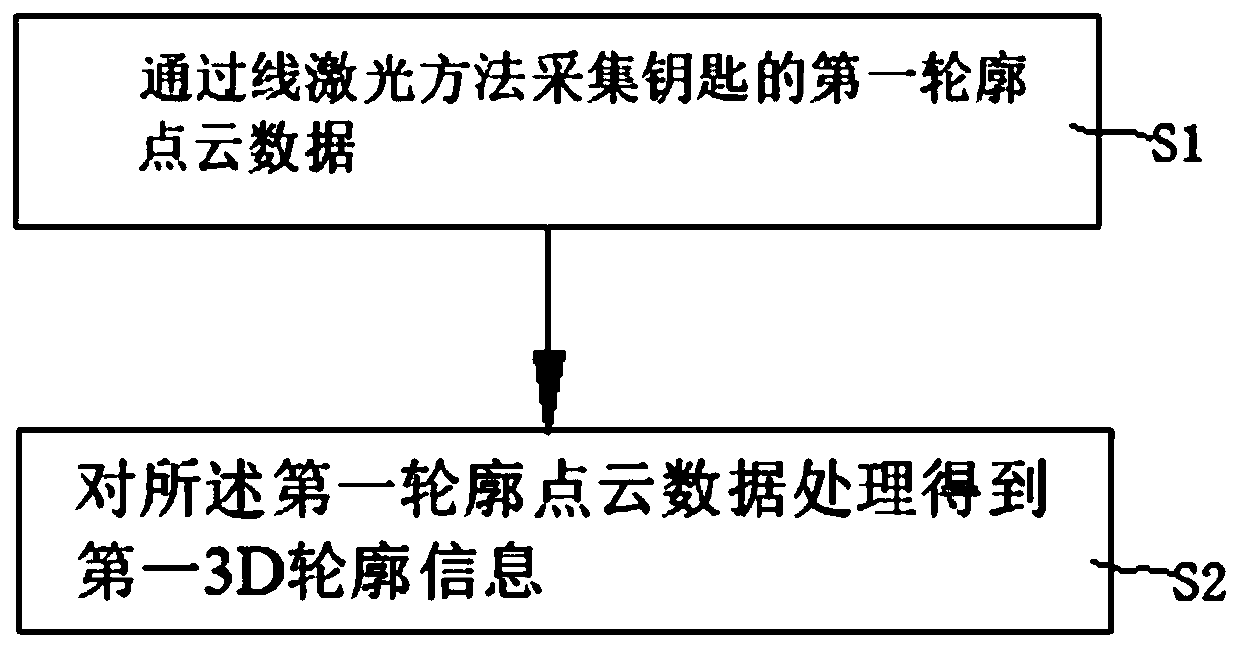

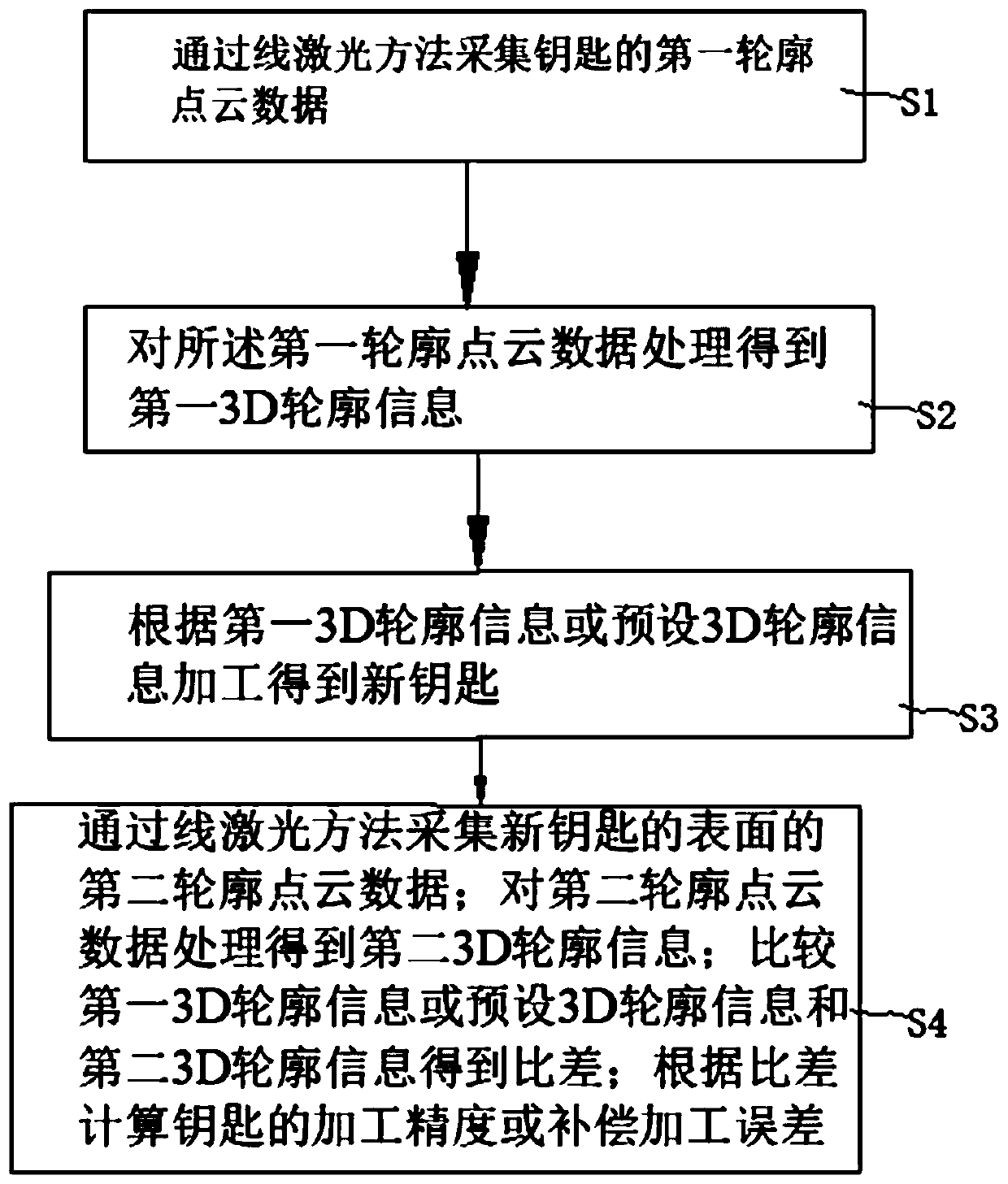

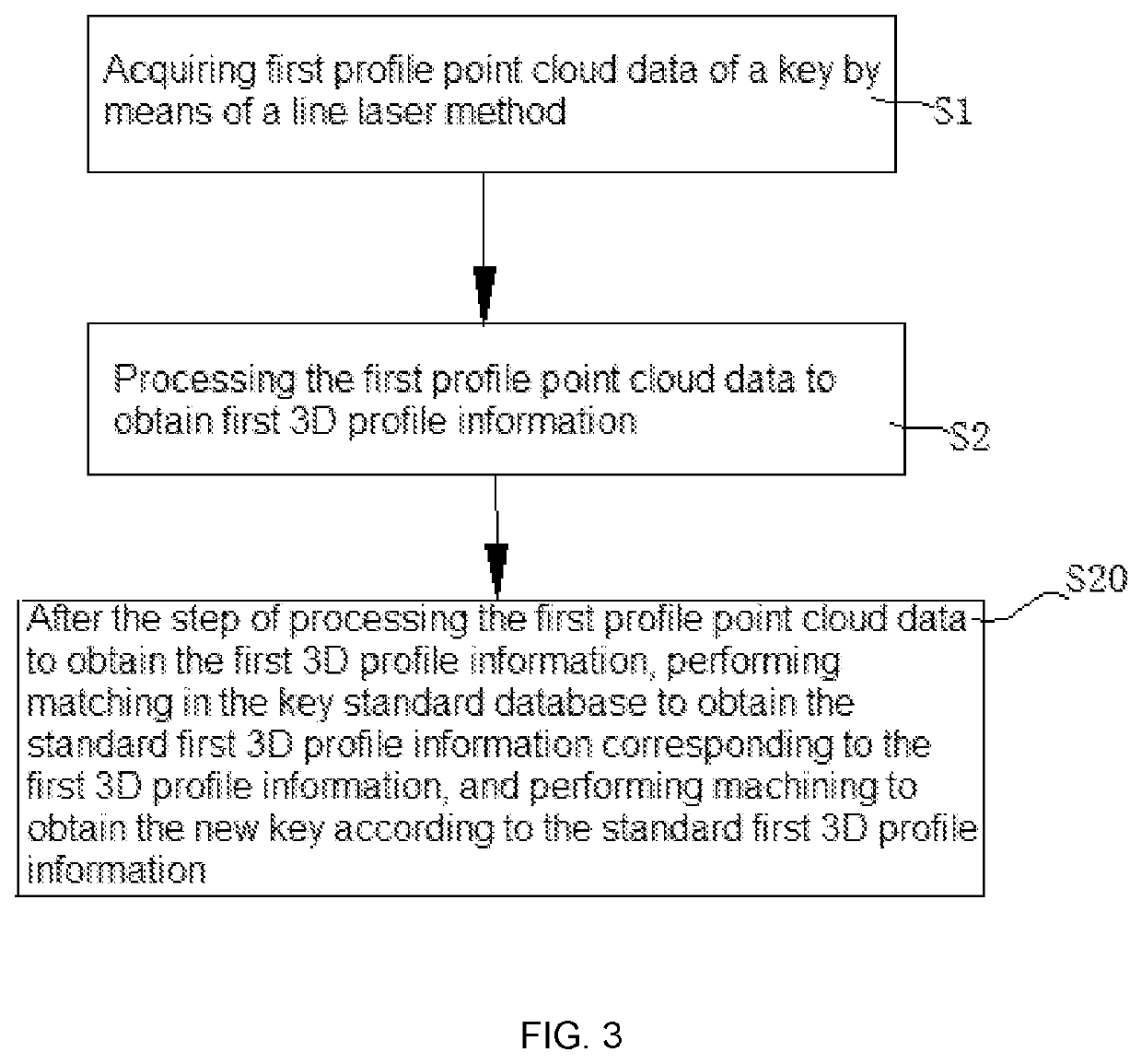

PendingCN110220479AAccurate acquisitionImprove applicabilityUsing optical meansKey-ways measurementsPoint cloudMedicine

The invention discloses a non-contact key tooth shape learning method and system. The non-contact key shape tooth learning method comprises the following steps that a first contour point cloud data ofa key are collected through a line laser method; and the first contour point cloud data are processed to obtain first 3D contour information. The non-contact key tooth shape learning method and system solve the problems that an existing key making method is poor in versatility, high in environmental requirements, complicated in operation and low in efficiency.

Owner:SHENZHEN SHUMA ELECTRONICS TECH

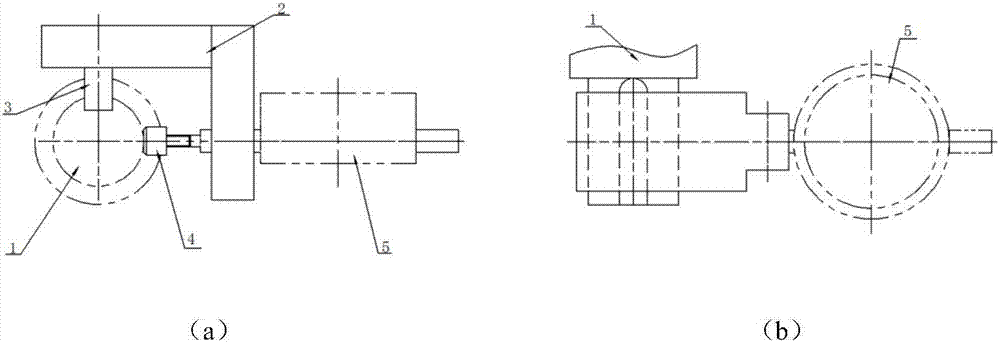

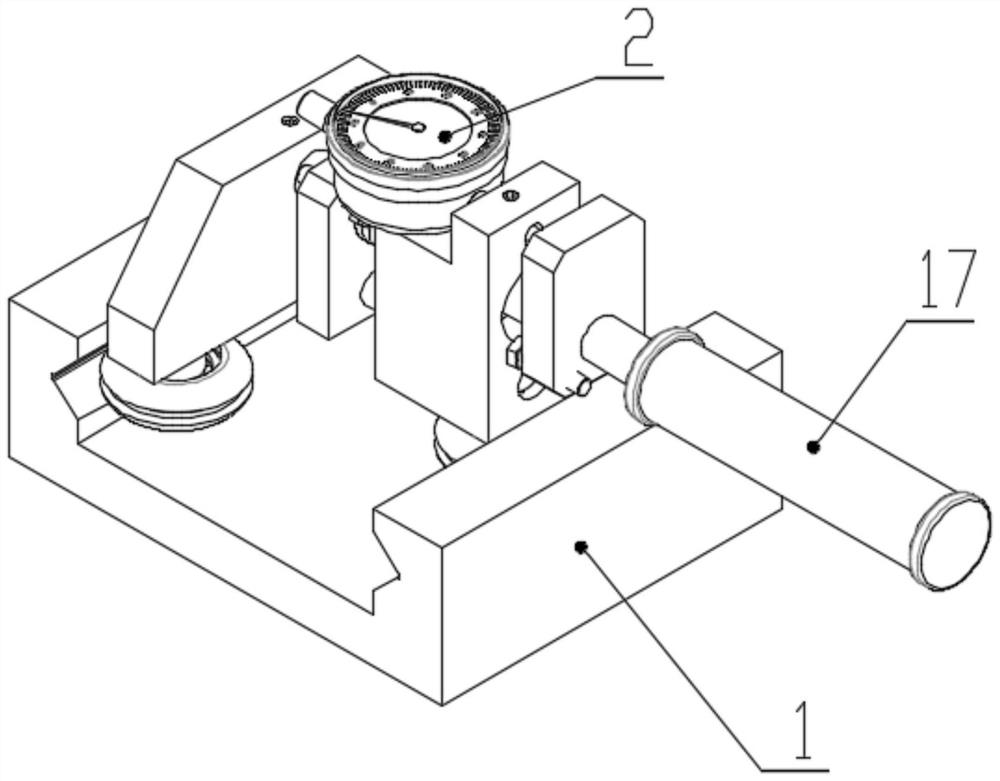

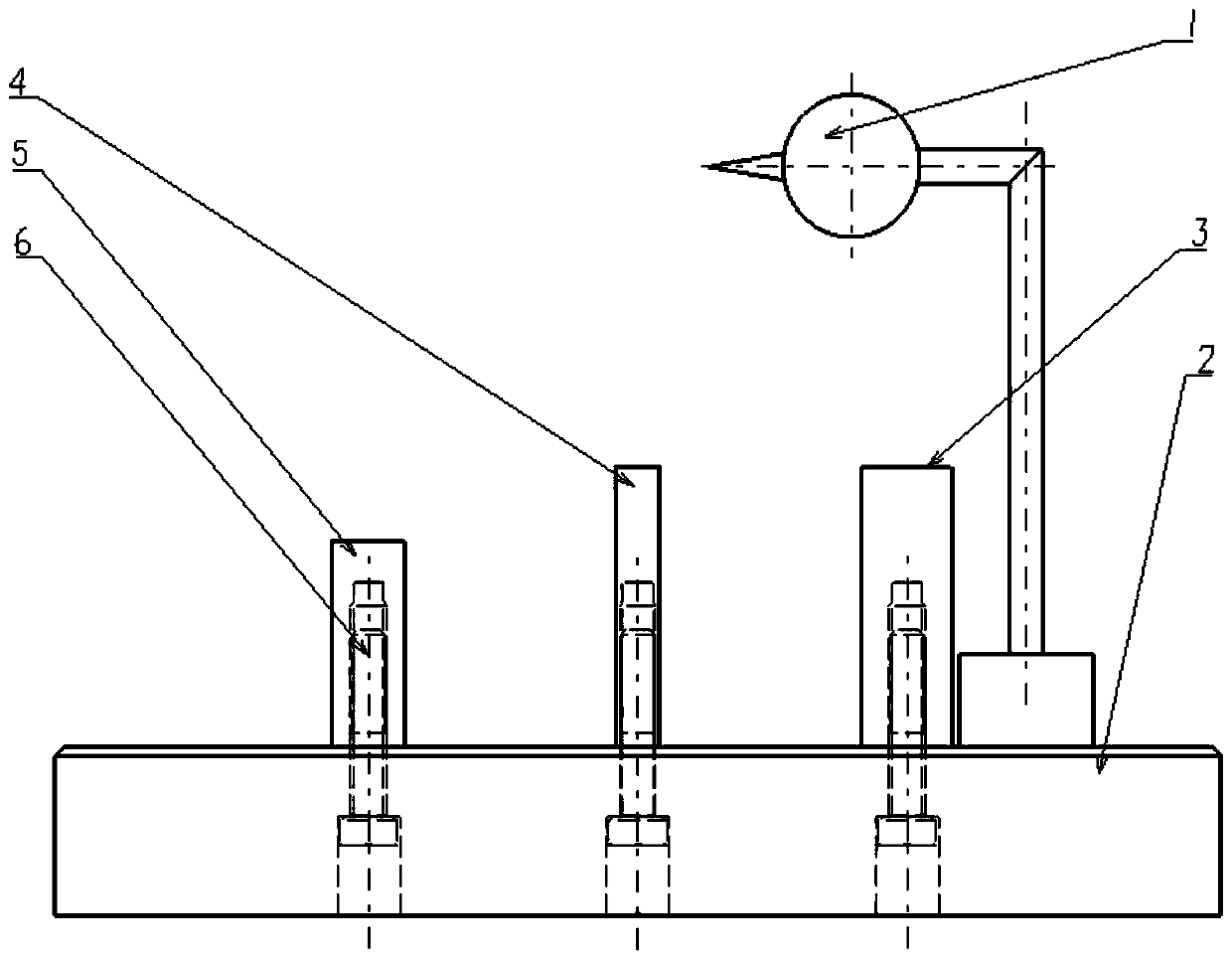

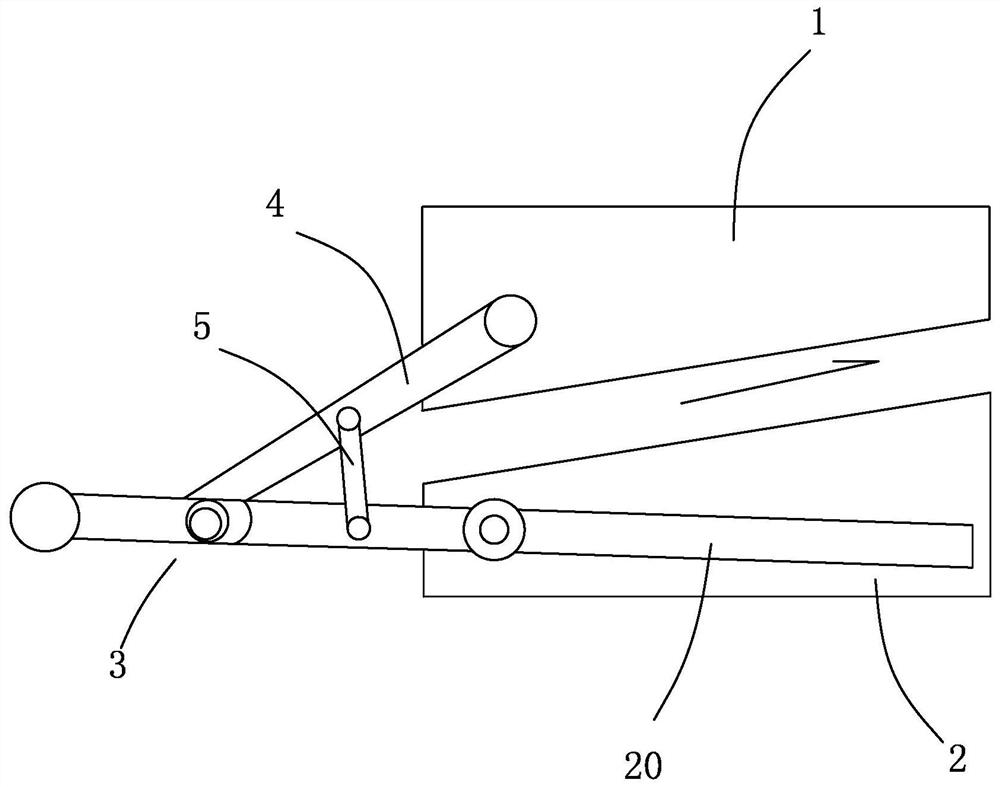

Off-axis single-key symmetry degree measuring device and measuring method

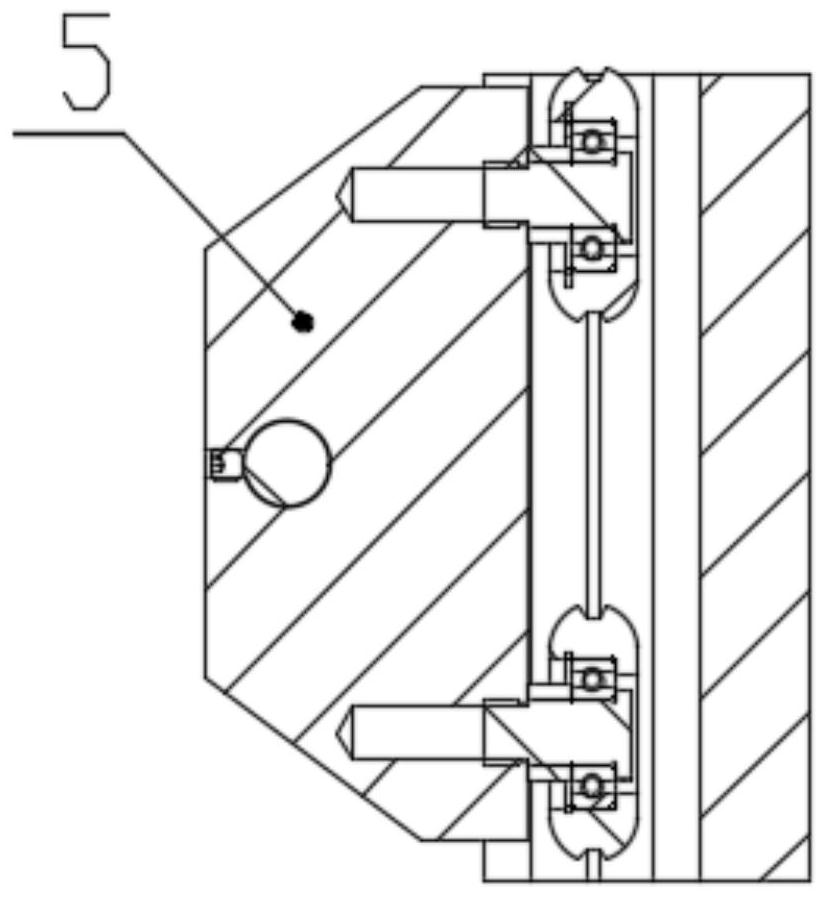

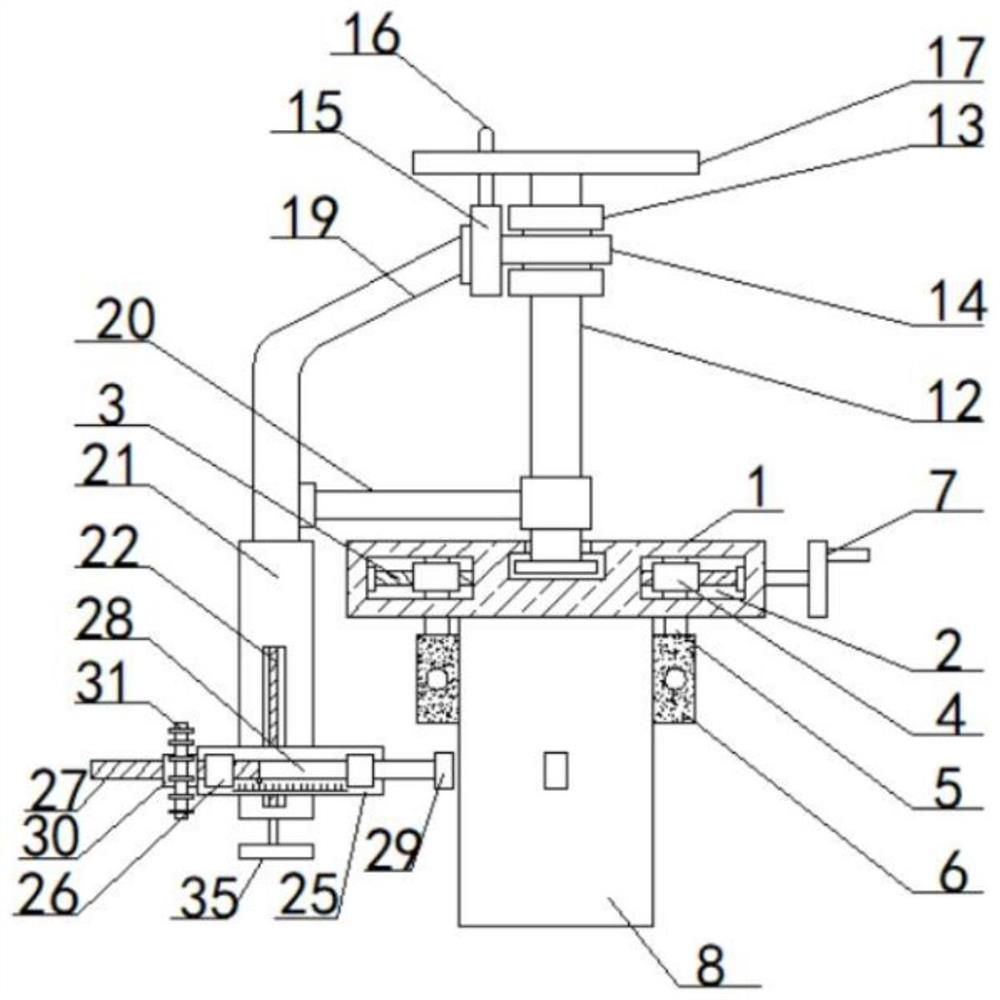

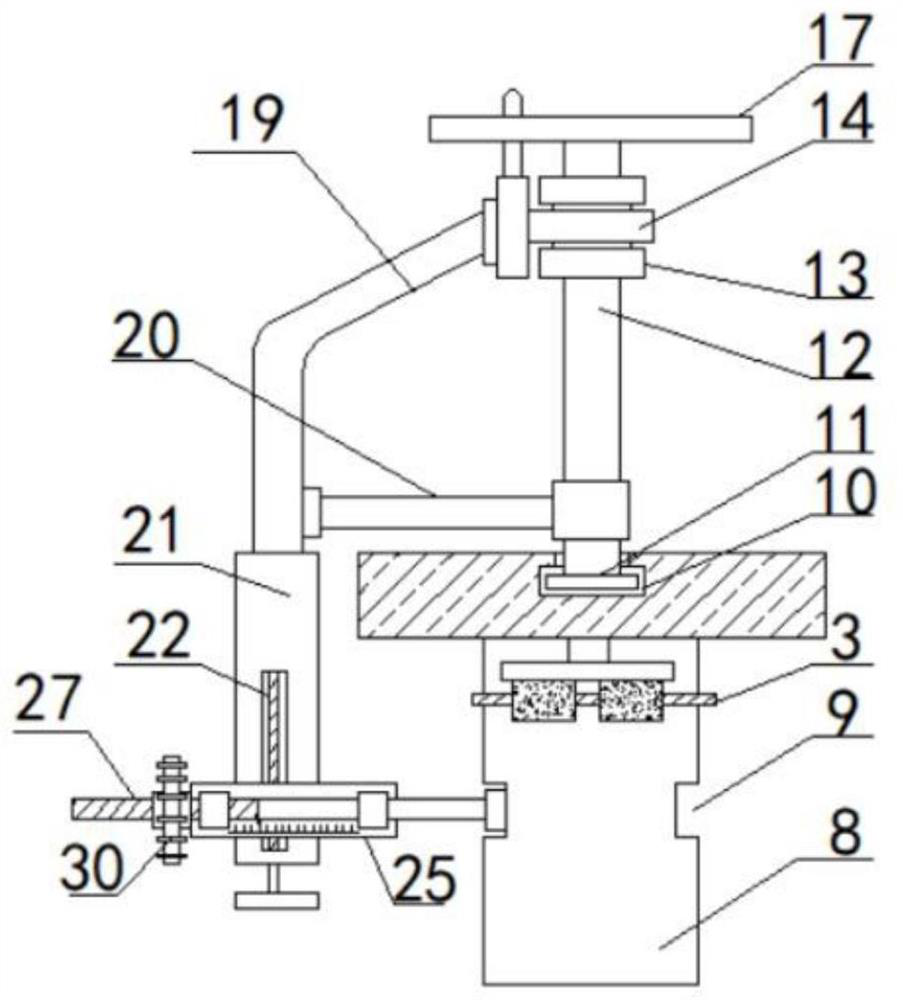

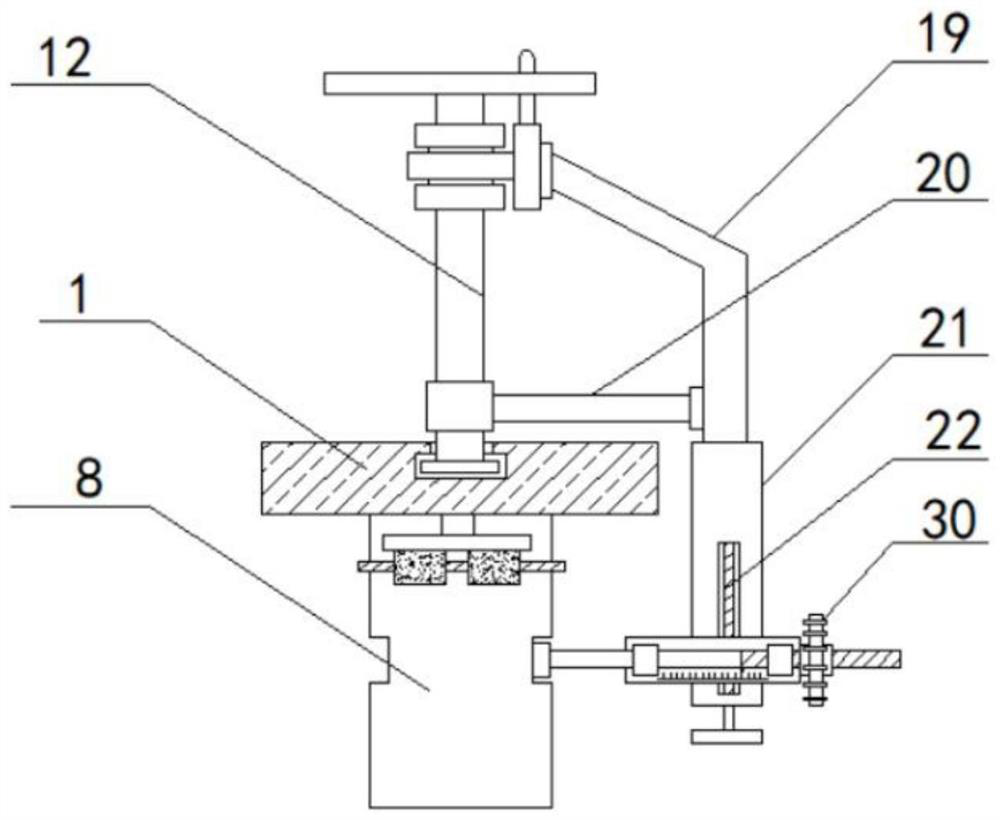

PendingCN107228615AAccurate and reliable positioningIncrease contactKey-ways measurementsGroove widthMeasurement device

The invention discloses an off-axis single-key symmetry degree measuring device and an off-axis single-key symmetry degree measuring method. The off-axis single-key symmetry degree measuring device comprises a measuring device body and a positioning block, wherein the positioning block is arranged at the lower part of a cross rod of the measuring device body, and one end of the positioning block is clamped in a single-key groove of a workpiece to be measured during measurement; and the middle part of a vertical rod of the measuring device body is connected with a dial indicator, the top end of the dial indicator is connected with a measuring head of a cylindrical structure, and the measuring head is in contact with a workpiece for measuring a symmetry degree. The positioning block matched with the groove width of the processed workpiece is adopted, the positioning block is clamped into the single-key groove to serve as a positioning reference of the whole measuring device, the positioning is precise and reliable, the dial indicator is matched with the measuring head in the shape of a cylindrical surface, thus the measuring head can be in contact with the highest point of an excircle section of the workpiece, and the influence of the roundness of the excircle section and straightness errors can be ignored.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Lift installation having a compensating device, so that a first roller is largely relieved of loading when the lift car is at rest

ActiveCN107108159AReduce in quantityIncrease stiffnessLoading/unloading vehicle arrangmentElevatorsMechanical engineeringGravitation

Owner:TK ELEVATOR INNOVATION & OPERATIONS GMBH

Automatic spline recognition device for bearing processing

The invention provides an automatic spline recognition device for bearing processing, which comprises a base, wherein the base is provided with a bearing placement platform, a press-fitting cylinder is arranged right above the bearing placement platform, the press-fitting cylinder performs press-fitting on a bearing component, the bearing placement platform is provided with an internal spline detection block, the internal spline detection block is provided with an internal spline detection groove, the position of an internal spline of a product is detected through the internal spline detectiongroove, an external spline detection block is arranged between the bearing placement platform and the press-fitting cylinder at one side, the external spline detection block is provided with a detection groove, detection is performed on an external spline through the detection groove, the rear part of the external spline detection block is provided with a telescopic cylinder, the external splinedetection block is driven to move through the telescopic cylinder so as to get close to a bearing. The automatic spline recognition device performs detection on an internal spline of a bearing throughthe internal spline detection block and performs detection on an external spline of the bearing through the external spline detection block when the bearing is placed, thereby automatically completing the detection work, and improving the detection efficiency. The automatic spline recognition device shifts a bearing which is incorrectly placed through a shifting rod so as to adjust the position of the bearing.

Owner:NEXTEER LINGYUN DRIVELINE WUHU

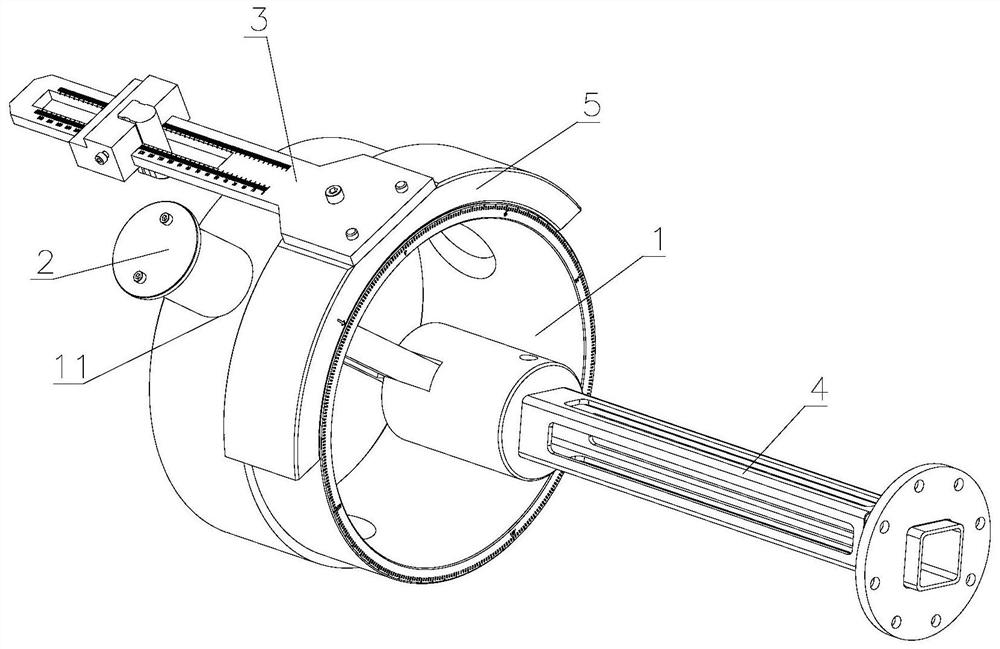

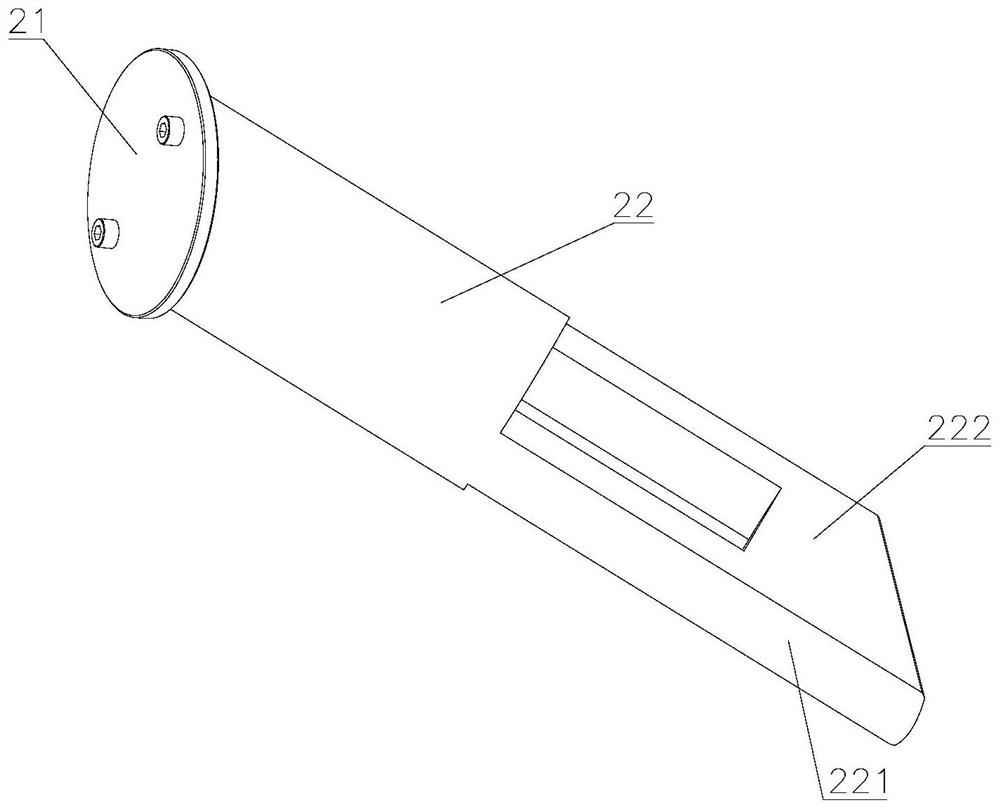

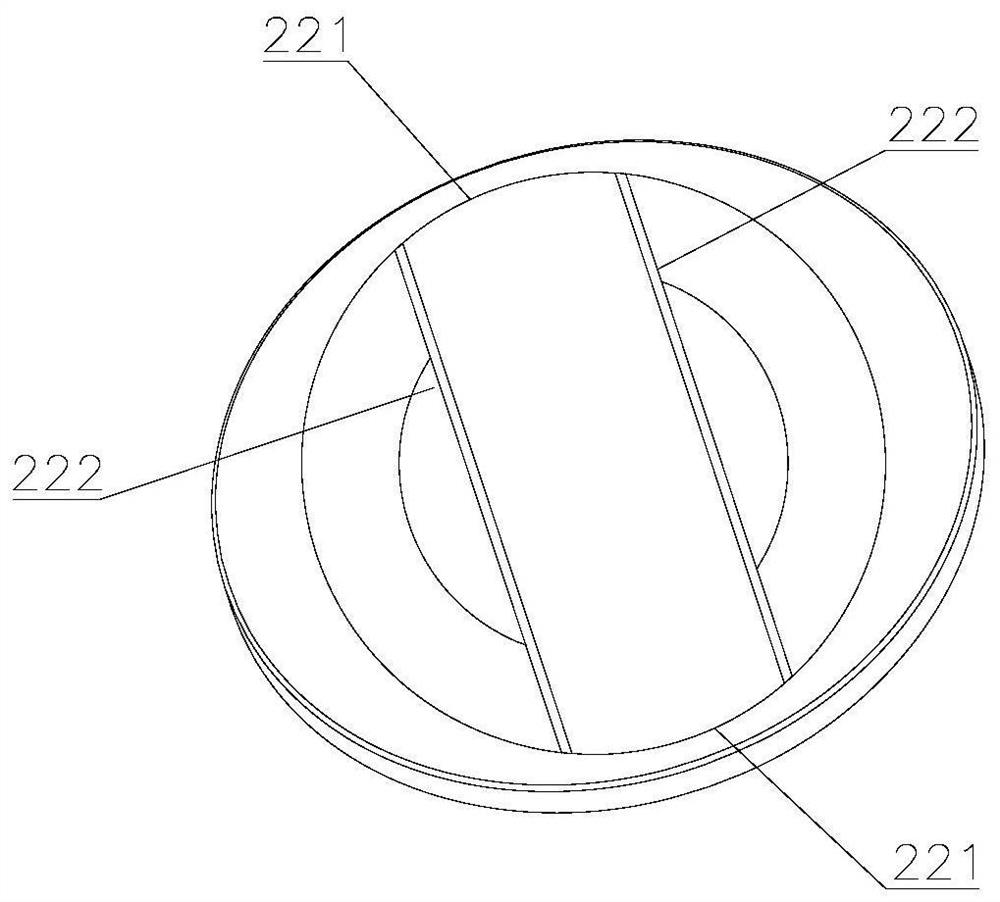

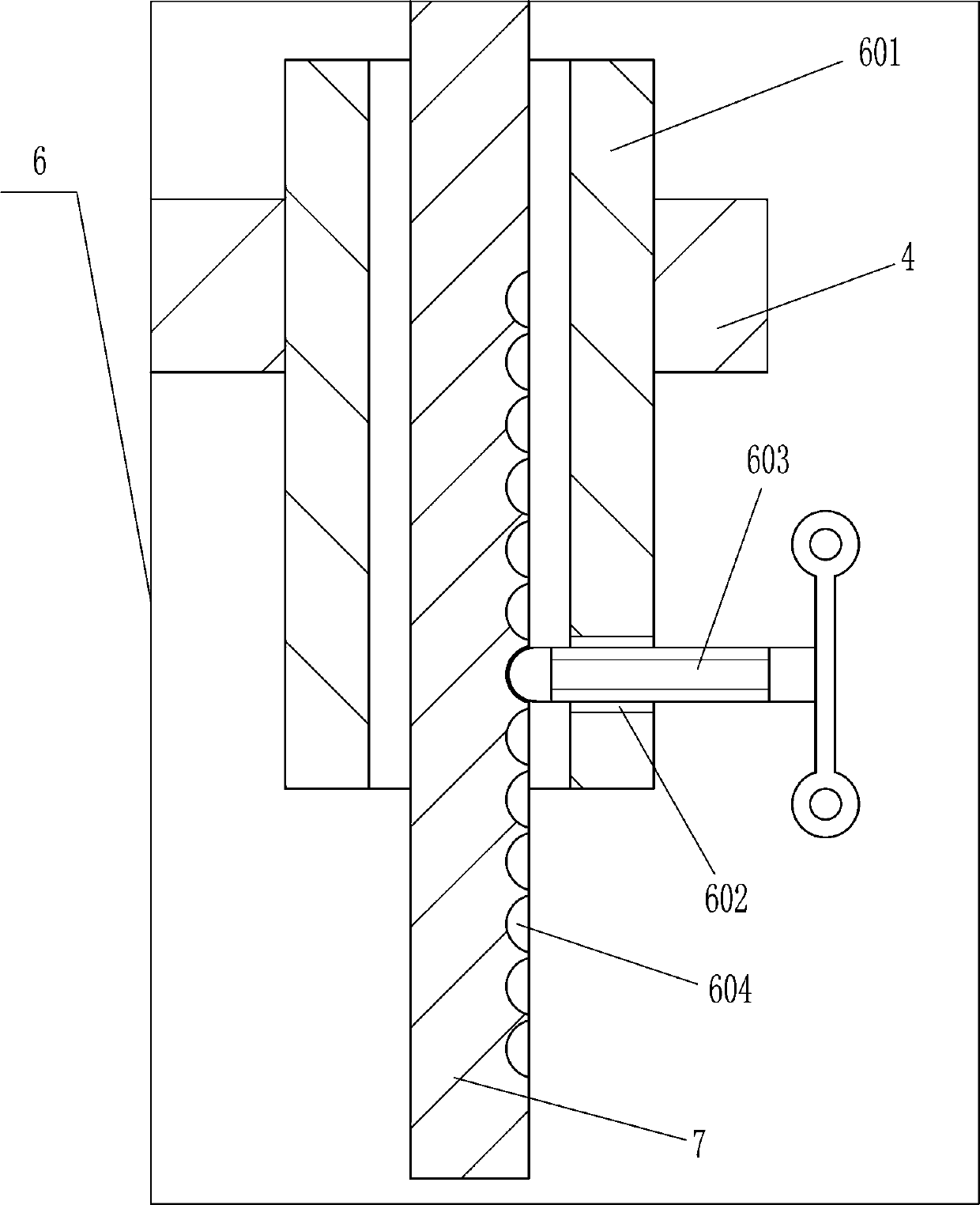

Wind power shaft testing fixture

PendingCN112013740ASimple structureEasy to operateAngles/taper measurementsMechanical clearance measurementsMeasurement deviceEngineering

The invention relates to a wind power shaft testing fixture, which comprises a cylinder which is used for sleeving a wind power shaft; a positioning device used for being inserted into a wire hole inthe wind power shaft; a measuring device used for clamping a key groove in the wind power shaft and measuring the distance between the key groove and the wire hole; a detection device inserted into the inner hole of the wind power shaft and used for detecting the threaded hole in the end surface of the wind power shaft; and an angle ruler used for measuring an included angle between the wire holeof the wind power shaft and the key groove. Firstly, the wind power shaft is inserted into the cylinder body and fixed under the clamping effect of the positioning device and the wire hole, then the included angle between the wire guide hole of the wind power shaft and the key groove in the radial direction of the wind power shaft is measured through the angle ruler, and the measuring device measures the distance between the key groove and the wire hole in the axial direction of the wind power shaft, so that whether the detected numerical value meets the production requirement is judged. The wind power shaft positioning device, the measuring device and the detection device jointly detect the position relation of the wind power shaft key groove, the wire hole and the end face threaded hole,and the detecting precision is improved.

Owner:常州优谷新能源科技股份有限公司

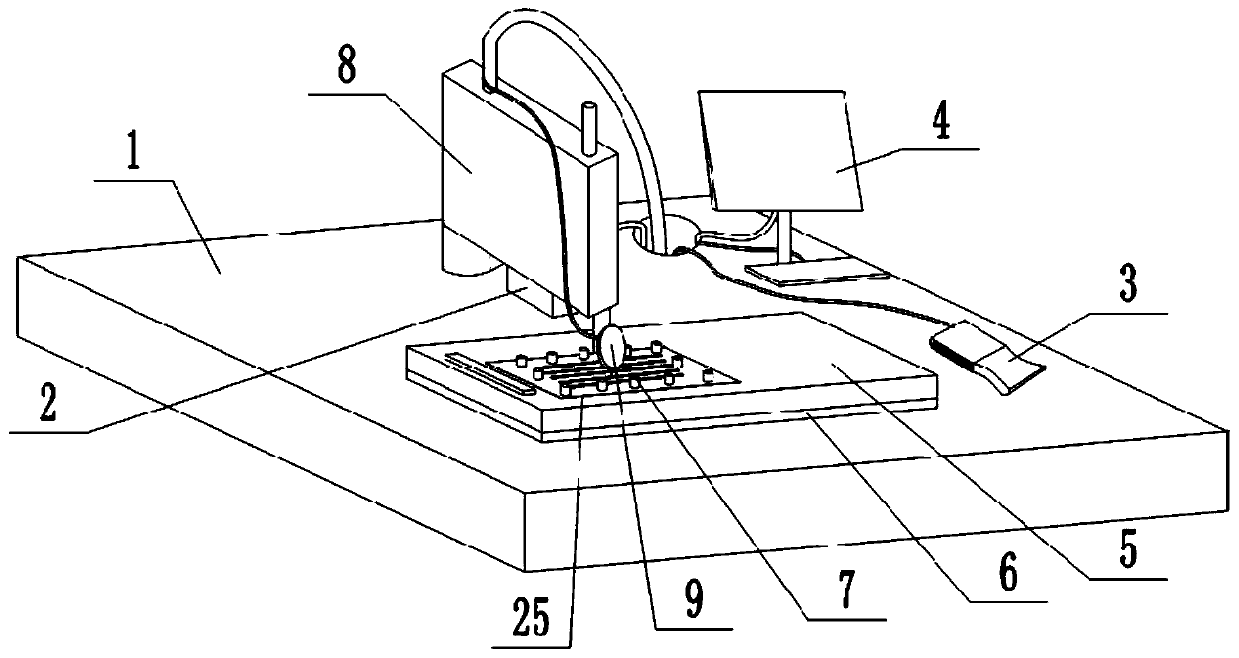

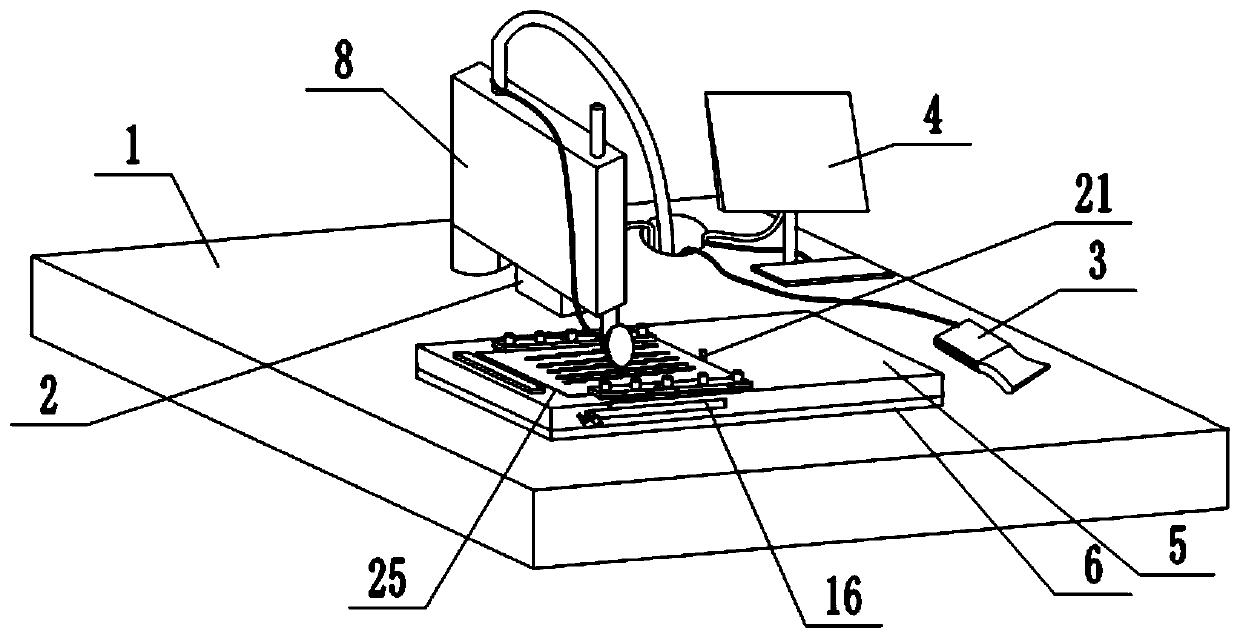

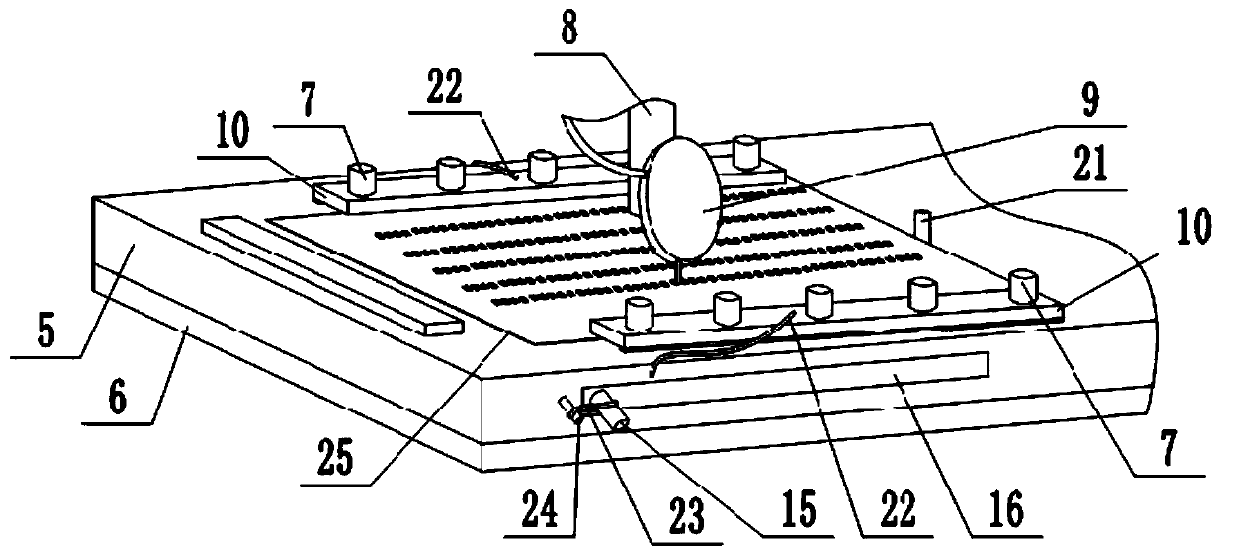

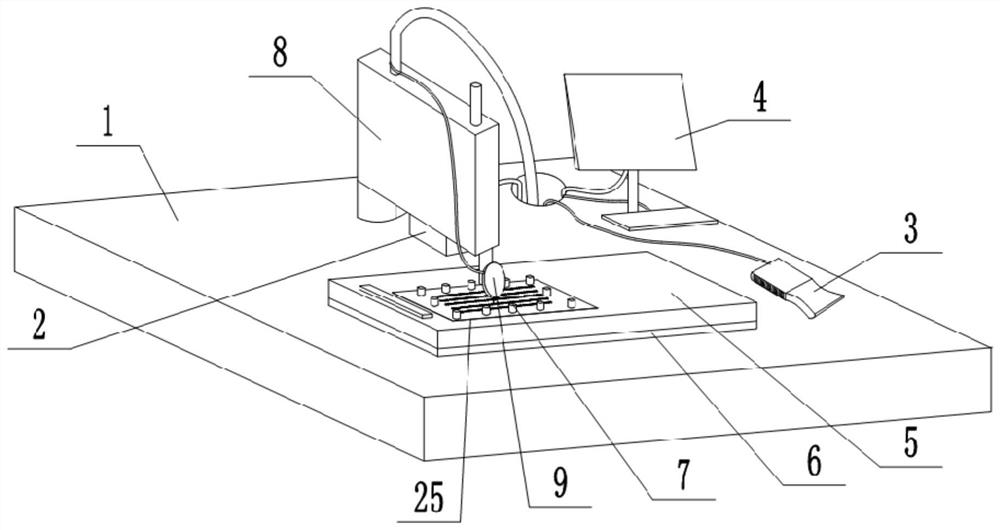

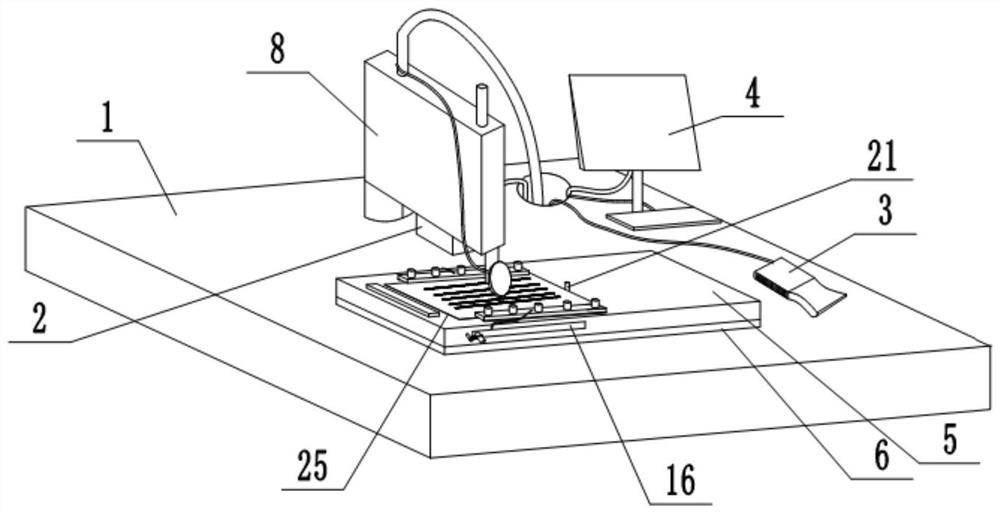

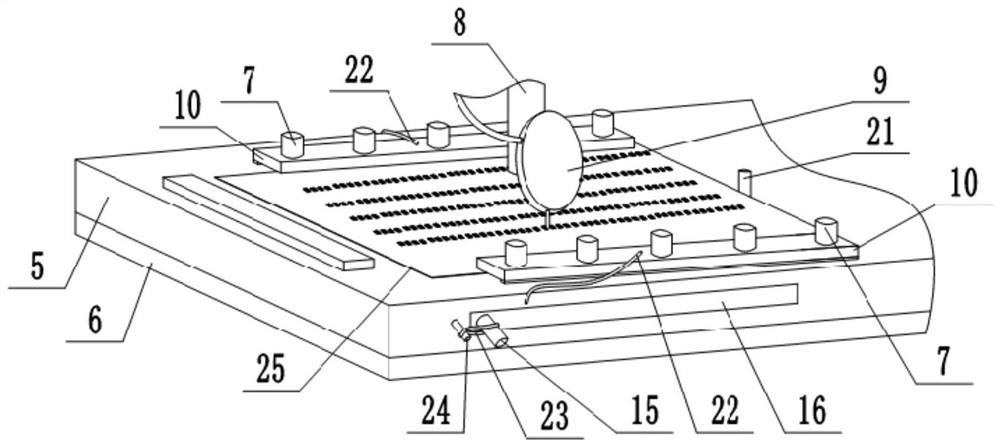

Automatic keyboard bottom plate detection device

ActiveCN110030903AImprove detection efficiencyImprove accuracyMechanical thickness measurementsKey-ways measurementsData displayDisplay device

The invention relates to the technical field of detection, and discloses an automatic keyboard bottom plate detection device. The automatic keyboard bottom plate detection device comprises a workbench; the workbench is provided with a mounting base, a demonstrator, a computer and a detection platform; a mechanical arm is rotationally connected to the mounting base, and the mechanical arm is connected with the demonstrator; a digital display dial indicator is arranged at the bottom of the mechanical arm and is connected with the computer; an electromagnet is arranged at the bottom of the detection platform, and the bottom of the electromagnet is connected with the workbench; and the top of the detection platform is detachably connected with a plurality of limiting blocks capable of being attracted by the electromagnet. According to the automatic keyboard bottom plate detection device provided by the invention, the movement track of the mechanical arm is controlled through the demonstrator; a hook on a keyboard bottom plate is detected through the digital display dial indicator, detected data are transmitted to the computer, and the data are displayed through a display of the computer, so that whether the height of the hook meets the production requirement is calculated; and the detection efficiency of the keyboard bottom plate is greatly improved, and the detection accuracy is higher than that of manual detection.

Owner:重庆丰川电子科技有限公司

Keyboard bottom plate automatic detection device

ActiveCN110030903BImprove detection efficiencyImprove accuracyMechanical thickness measurementsKey-ways measurementsData displayRobot hand

The invention relates to the technical field of detection, and discloses an automatic keyboard bottom plate detection device. The automatic keyboard bottom plate detection device comprises a workbench; the workbench is provided with a mounting base, a demonstrator, a computer and a detection platform; a mechanical arm is rotationally connected to the mounting base, and the mechanical arm is connected with the demonstrator; a digital display dial indicator is arranged at the bottom of the mechanical arm and is connected with the computer; an electromagnet is arranged at the bottom of the detection platform, and the bottom of the electromagnet is connected with the workbench; and the top of the detection platform is detachably connected with a plurality of limiting blocks capable of being attracted by the electromagnet. According to the automatic keyboard bottom plate detection device provided by the invention, the movement track of the mechanical arm is controlled through the demonstrator; a hook on a keyboard bottom plate is detected through the digital display dial indicator, detected data are transmitted to the computer, and the data are displayed through a display of the computer, so that whether the height of the hook meets the production requirement is calculated; and the detection efficiency of the keyboard bottom plate is greatly improved, and the detection accuracy is higher than that of manual detection.

Owner:重庆丰川电子科技有限公司

A special measuring tool for measuring keyway symmetry of shaft parts

InactiveCN109682288BKnow asymmetryEasy to moveAngles/taper measurementsKey-ways measurementsGear wheelHand pain

The invention relates to a special measuring tool, in particular to a special measuring tool for measuring the symmetry degree of a shaft part key groove and solve the technical problem that people can measure the symmetry degree of the shaft part key groove conveniently, a manual ruler is not needed, and the phenomenon that the efficiency is affected by hand pain is avoided. The technical schemeof the special measuring tool for measuring the symmetry degree of the shaft part key groove comprises a hollow handle, a first support bar, a support plate, an adjusting device, a first measuring rodand the like; the first support rod is fixedly connected to the lower part of the left side of the front side of the hollow handle, and a first gear is rotationally arranged at the upper part of therear side of the first support rod. According to the special measuring tool for measuring the symmetry degree of the shaft part key groove, under the action of the first measuring rod and the second measuring rod, a press block is pushed, the first measuring rod and the second measuring rod can measure the symmetry degree of the shaft part key groove, the manual ruler is not needed to measure theposition length of the key groove to obtain the symmetry degree, the operation is more convenient, and a detection shaft can move more smoothly in the hollow handle under the action of a universal ball.

Owner:JINGGANGSHAN UNIVERSITY

Self-centering mandrel for golf club hosels

ActiveUS11504591B2Reduce variationAccurate measurementUsing optical meansKey-ways measurementsErbium lasersGolf club

A laser mandrel system that self-centers within a hosel bore of a golf club head to allow for precision adjustment of lie and loft is disclosed herein. The mandrel includes a one-piece housing with upper and lower portions, a laser centered within the upper portion of the housing, and a plurality of o-rings extending around an exterior or interior surface of a lower portion of the housing.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Worm gear center hole detection marking device

InactiveCN108204778AImprove the efficiency of angle detectionCompact structureKey-ways measurementsComputer engineering

The invention discloses a worm gear center hole detection marking device which is characterized by comprising a detection plate with a center hole, a key groove corresponding to the position of the key groove of the center hole of a to-be-tested worm gear, a key matched with the key slot is additionally arranged, a side hole corresponding to the position of the side hole of the worm gear is further formed in the detection board, and two key grooves in the center hole are formed and oppositely arranged on the wall of the central hole and oppositely arranged on the two sides of the two key grooves. By the adoption of the scheme, the device is compact in structure, and convenient to use, and is tidy and attractive, and the detection efficiency of the included angle between the two holes of the worm gear can be improved. The accuracy of the detection is ensured, the processing is fast, and the production cost is greatly reduced.

Owner:杨润

A measuring tool and measuring method for wear amount of involute inner spline

ActiveCN111102895BHigh measurement accuracyThe measured value is stableKey-ways measurementsInvestigating abrasion/wear resistanceMicrometer scaleEngineering

The invention relates to a measuring tool, in particular to an involute internal spline abrasion loss measuring tool and a measuring method thereof, and aims to solve the problem of low internal spline abrasion loss measuring precision in the prior art. The involute internal spline abrasion measuring tool comprises a modified inside micrometer and a standard part. The modified inside micrometer comprises three measuring heads. The working ends of the measuring heads are ball heads, and the ball centers of the ball heads of the three measuring heads are located on the same circumference. The invention further provides an involute internal spline abrasion loss measuring method. The method comprises the following steps: (1) using a standard part for zero setting to modify the inside micrometer; 2) inserting the refitted inside micrometer into a tooth socket of the measured involute internal spline, wherein the reading of the refitted inside micrometer is [delta]M; and 3) calculating to obtain an [delta]S value according to the corresponding relationship between the [delta]S value and the [delta]M value, and obtaining the wear condition of the measured involute internal spline when theresidual tooth thickness of the measured involute internal spline is equal to the difference of the tooth thickness of the standard part and the [delta]S value.

Owner:国营四达机械制造公司

Detection method for run-out of inner diameter groove

ActiveCN112833731AReduce manufacturing costIncrease productivityKey-ways measurementsManufacturing engineeringMechanical engineering

The invention relates to a detection method for run-out of an inner diameter groove. The method comprises the following steps: S1, manufacturing a high-precision measuring tool block; S2, collecting circle centers in multiple directions to form a fitting circle; s3, judging whether the circle of the inner diameter groove is qualified relative to the benchmark B by evaluating the run-out relation between the fitting circle and the benchmark B. According to the detection method, inner diameter groove run-out detection is carried out, measurement can be carried out by fully utilizing an existing three-coordinate system only by spending a small amount of cost to manufacture a corresponding measuring tool block, and it is not needed to consume too long time to load an expensive star-shaped measuring head, so that the production cost is greatly reduced, and the production efficiency is improved. The detection method can be widely applied to measurement of the run-out of the inner diameter groove with the run-out requirement larger than or equal to 0.1.

Owner:WUXI LIHU PRESSURIZE TECH CO LTD

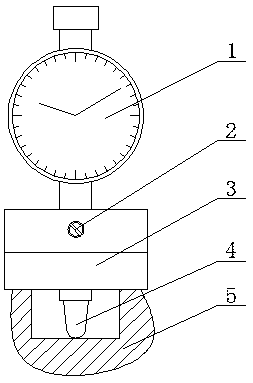

Groove depth measuring instrument

InactiveCN109141192AEasy to operateMechanical depth measurementsKey-ways measurementsMeasuring instrumentEngineering

The invention relates to a groove depth measuring instrument. The groove depth measuring instrument is characterized in that the upper part of a measuring rod is provided with a dial gauge outfit; thelower part of the measuring rod is provided with a stopping block; a positioning screw is arranged between the stopping block and the measuring rod. With the groove depth measuring instrument adopted, the problem of the inaccuracy of the measurement of the depth of a key groove or seal groove of a workpiece can be solved. The groove depth measuring instrument is a best tool for measuring the keyway of a workpiece in the machining field.

Owner:郑鑫

Movable workbench V-groove inspection tool and inspection method thereof

PendingCN114812333AReduce the impactEasy to operateKey-ways measurementsStructural engineeringWorkbench

The invention provides a movable workbench V-groove inspection tool which comprises a positioning shaft, a fixing plate, a front positioning plate, a floating gauge stand and a rear positioning plate are sequentially connected to the positioning shaft in series, groove-shaped rollers are arranged at the bottoms of the floating gauge stand and the fixing plate and located in a V-shaped groove of a V-shaped sample block, a spring is arranged between the floating gauge stand and the front positioning plate, and the groove-shaped rollers are located in the V-shaped groove of the V-shaped sample block. A dial indicator is arranged on the floating gauge stand; the fixing plate, the front positioning plate and the rear positioning plate are all fixed on the positioning shaft, and the floating gauge stand is slidably installed on the positioning shaft. The invention further provides a movable workbench V-groove inspection method. The device is of an integrally-assembled structure, the structure is not scattered, measurement is convenient, and the influence of measurement errors on a finished aluminum profile on the movable workbench is greatly reduced; the operation is simple, time and labor are saved, the use is convenient, a green hand can easily operate, the reading is visual, and the reading error is effectively reduced; the application range is wide.

Owner:GAOMI YONGLI MACHINERY

Measuring instrument for keyway depth and symmetry of motor shaft

ActiveCN111829411BEasy to installQuick measurementMechanical depth measurementsKey-ways measurementsElectric machineMeasuring instrument

Owner:JIANGSU YUANDONG ELECTRIC MOTOR MFG

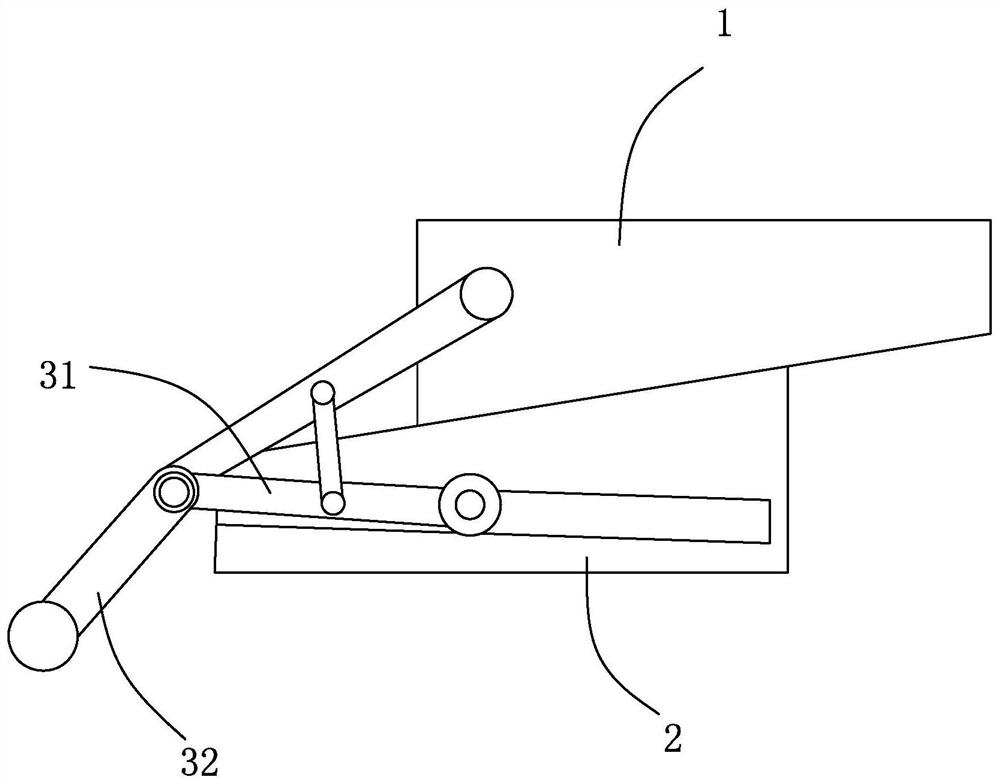

Elevator apparatus with compensating means so that the first roller is largely unloaded when the elevator car is stationary

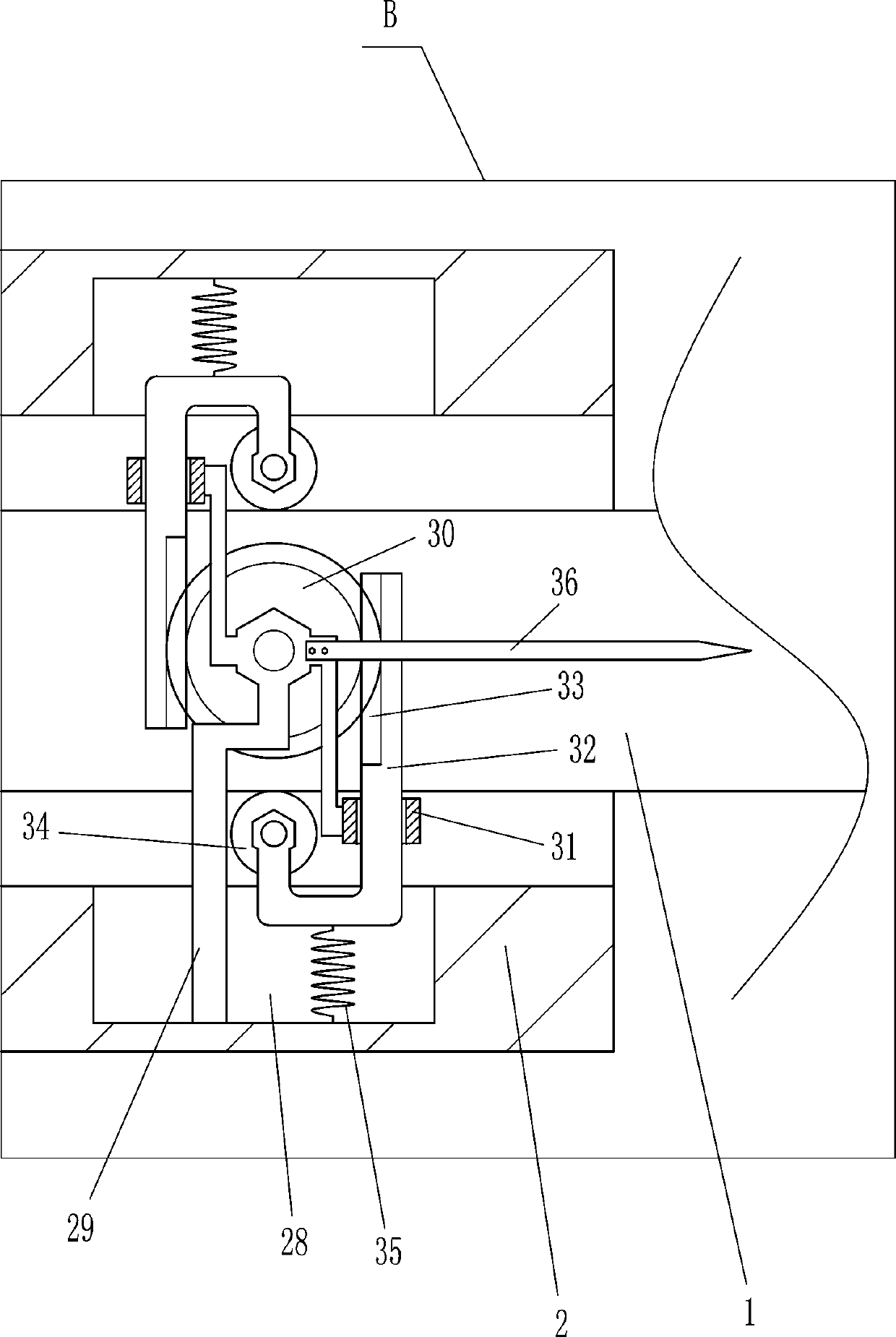

ActiveCN107108159BReduce in quantityIncrease stiffnessLoading/unloading vehicle arrangmentKey-ways measurementsGravity centerEngineering

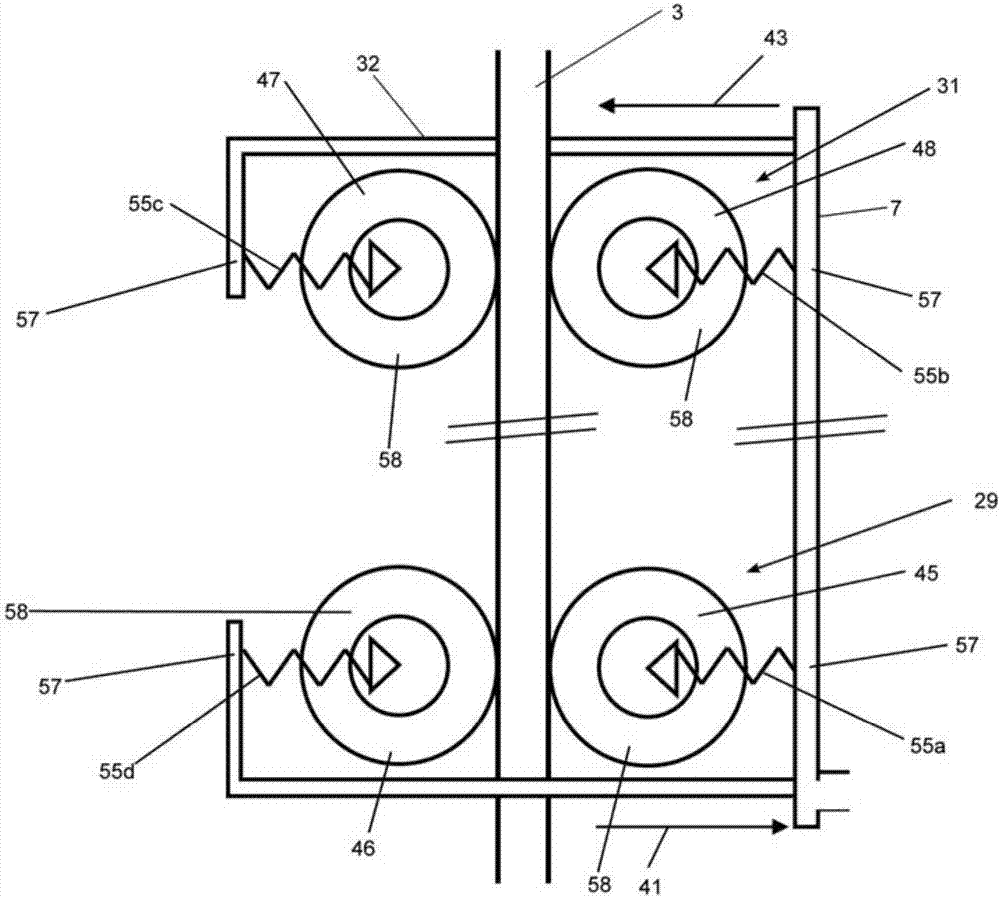

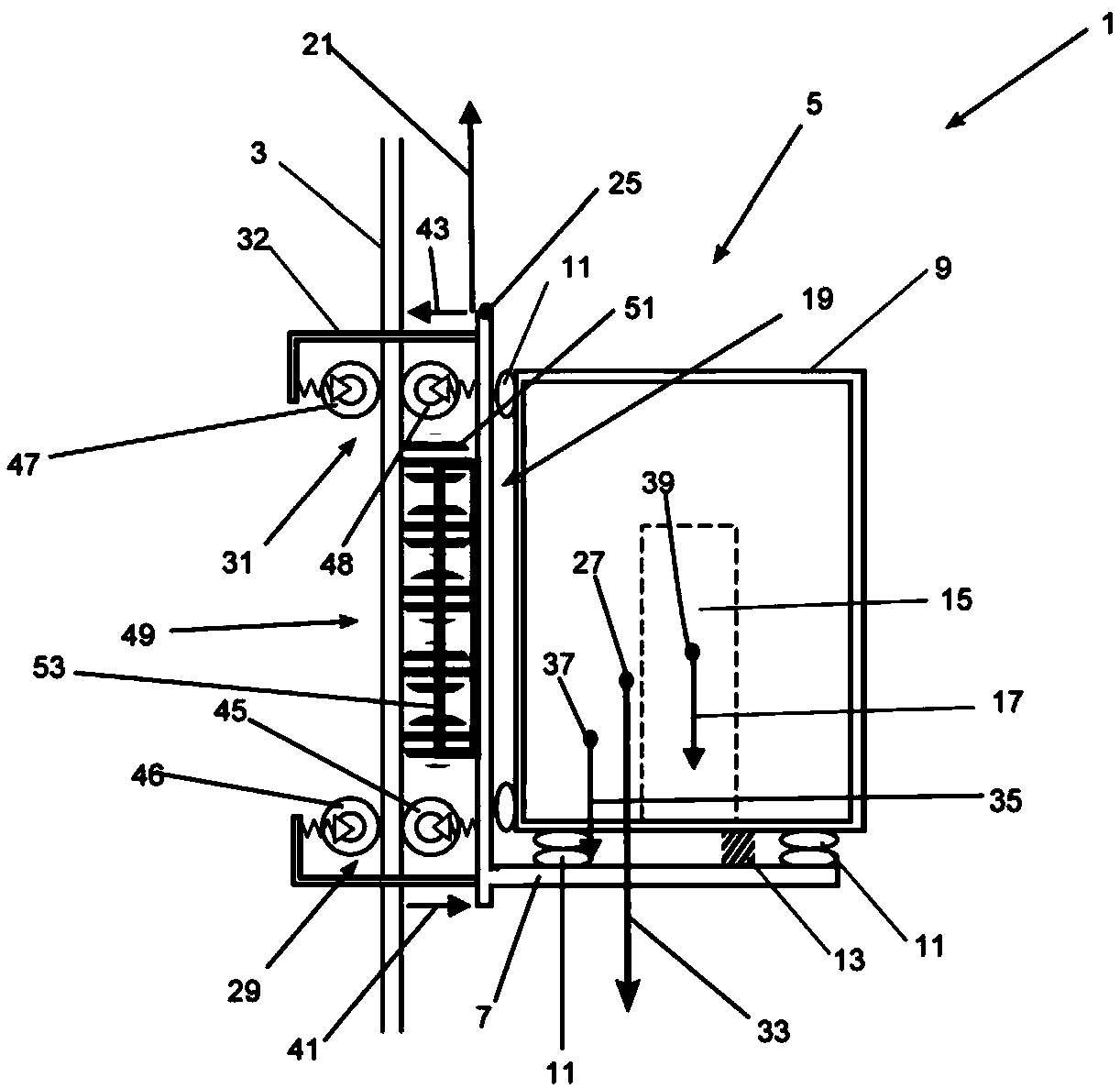

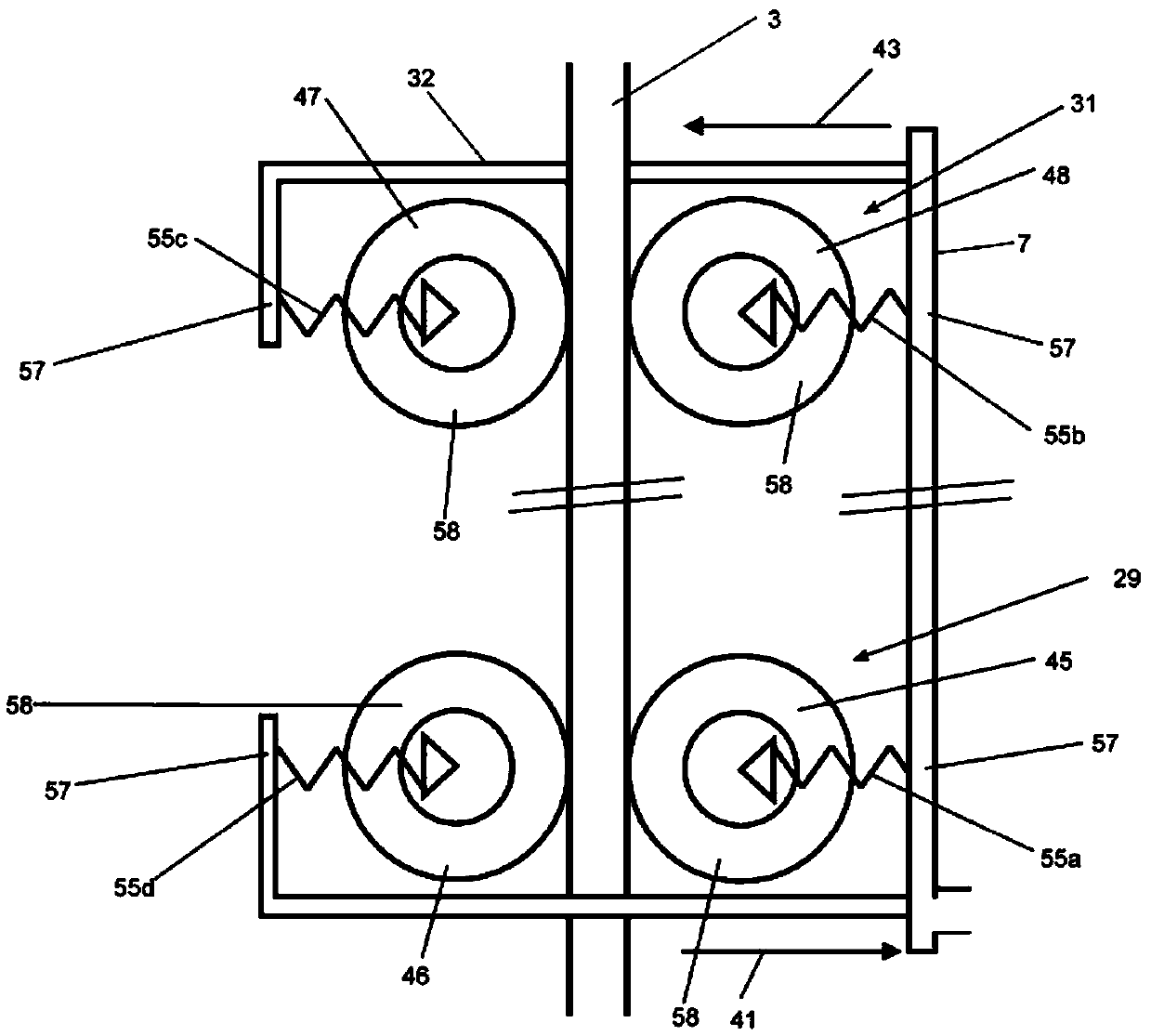

The invention relates to an elevator installation (1) having an elevator car (5) movable along a guide rail (3). The elevator arrangement here comprises at least a first pair of rollers ( 29 ) and a second pair of rollers ( 31 ). The guide rail (3) extends between the two rollers (45, 46) of the first roller pair (29) and between the two rollers (47, 48) of the second roller pair (31). The elevator installation (1) also has means (19) for subjecting the elevator car (5) to a holding force (21), wherein there is a horizontal offset between the point at which the holding force acts and the center of gravity of the elevator car , and thus subject the elevator car to a first moment. In addition, the elevator car has at least a first compensating device (63), so that when the elevator car (5) is at rest, the guide rail (3) is subjected to sufficient force to generate a second moment, which is largely The first moment is compensated such that the first roller (45) of the first roller pair (29) is largely unloaded when the elevator car (5) is at rest.

Owner:TK ELEVATOR INNOVATION & OPERATIONS GMBH

A device and method for detecting symmetry of rudder shaft grooves of rudder shaft parts

ActiveCN108007323BSimple structureImprove applicabilityKey-ways measurementsMagnetic tension forceClassical mechanics

Owner:CAPITAL AEROSPACE MACHINERY +1

Symmetry rapid test device

PendingCN110285747ASolve the problem that the degree of symmetry is not easy to detectSimple structureKey-ways measurementsEngineering

Owner:TIANJIN RAILWAY SIGNAL

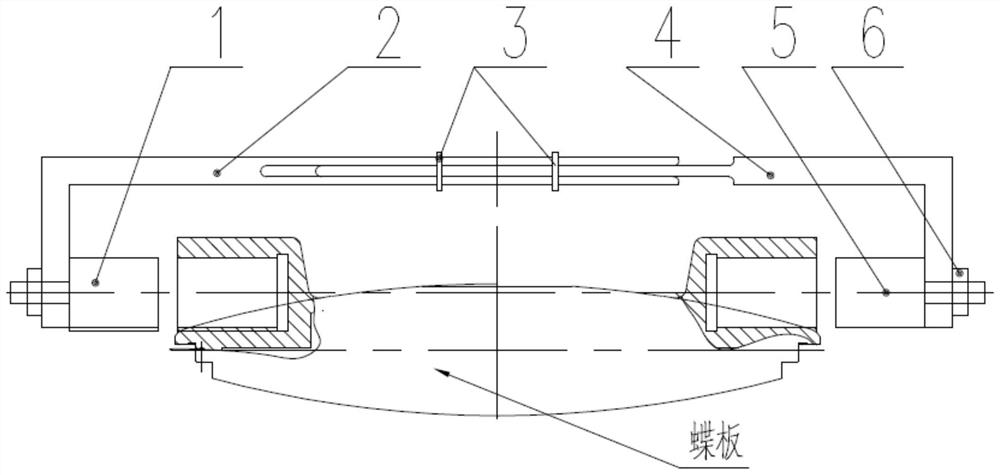

Tool for rapidly detecting geometric tolerance of shaft hole of butterfly valve and butterfly plate

PendingCN114526661AQuick measurementQuick checkMechanical counters/curvatures measurementsKey-ways measurementsEngineeringButterfly valve

The invention belongs to a detection tool, and particularly relates to a tool for rapidly detecting geometric tolerance of a shaft hole of a butterfly valve and a butterfly plate. The invention relates to a tool for rapidly detecting geometric tolerance of a shaft hole of a butterfly valve and a butterfly plate. The detection tool comprises a plug gauge with a key, a main cross beam, a limiting sleeve, an adjusting cross beam, a plug gauge and a nut. The tool has the advantage that the geometric tolerance of the shaft hole of the butterfly plate can be rapidly detected. The whole detection tool is an adjustable dynamic detection tool, the use is simple, after the detection tool is assembled, a proper plug gauge and a plug gauge with a key are matched, and the plug gauges are respectively aligned with the shaft holes at the two sides of the butterfly plate and are put into the shaft holes at the two sides of the butterfly plate, so that the form and location tolerance of key grooves in the shaft holes at the two sides and one side can be rapidly measured. Meanwhile, the full-depth form and location tolerance detection of the shaft hole of the butterfly plate can be realized by adjusting the movement of the cross beam. The plug gauge is fixed on the cross beam through the nut, so that the detection of butterfly plates with different specifications can be quickly completed within the adjusting range of the cross beam only by replacing a proper plug gauge, and the device has good universality.

Owner:SUFA TECH IND CNNC

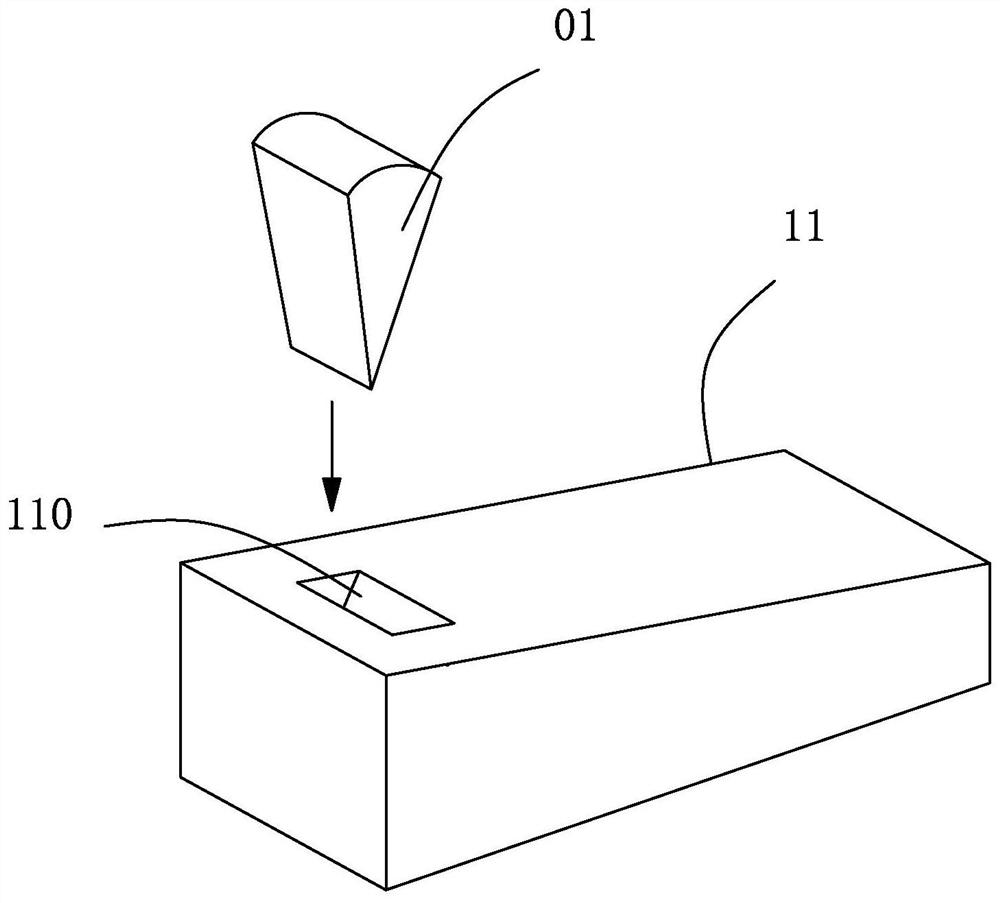

Non-contact key tooth profile learning method and system

PendingUS20220196392A1Low efficiencyHigh environmental requirementsUsing optical meansKey-ways measurementsPoint cloudAlgorithm

A non-contact key tooth profile learning method and system are provided. The non-contact key tooth profile learning method comprises the following steps: acquiring first profile point cloud data of a key by means of a line laser method; and processing the first profile point cloud data so as to obtain first 3D profile information.

Owner:SHENZHEN SHUMA ELECTRONICS TECH

Motor rotating shaft keyway depth and symmetry degree measuring instrument

ActiveCN111829411AEasy to installQuick measurementMechanical depth measurementsKey-ways measurementsElectric machineMeasuring instrument

The invention relates to the technical field of motor production, and discloses a motor rotating shaft keyway depth and symmetry degree measuring instrument, which comprises a dial; a rotating slidinggroove is formed in the middle of the dial; a connecting bent rod is fixedly connected to the left side of the connecting base; a supporting rod is fixedly connected to the right side of the bottom of the connecting bent rod; a vertical sliding measurement base is fixedly connected to the bottom of the connecting bent rod; and a horizontal sliding measurement base is fixedly connected to the front side of the vertical connecting block. A graduated scale threaded rod is driven to slide rightwards by rotating a rotating sleeve; further, a measuring mold is driven to extend into a double-key groove, and the position data of the graduated scale on the surface of a horizontal sliding measurement base at the moment is recorded; the connecting bent rod is rotated by 180 degrees to the outside ofthe double-key groove on the opposite side, the previous measurement process is repeated to read the data of the graduated scale on the surface of the horizontal sliding measurement base, and the twopieces of data is subtracted, so that the effect of accurate positioning and rapid measurement is achieved.

Owner:JIANGSU YUANDONG ELECTRIC MOTOR MFG

A device for measuring the arc tooth space width of internal splines

ActiveCN111780643BGuaranteed positioningAvoid instabilityKey-ways measurementsMeasuring instrumentEngineering

The present invention relates to a measuring instrument, more specifically, it relates to a measuring device for internal spline arc tooth groove width, which includes a pair of upper wedge-shaped upper and lower wedges with flat bottom and inclined surfaces with the same inclination angle. The upper wedge block and the lower wedge block are provided with two corresponding chutes on the slope of the upper wedge block, the corresponding two chute slots on the lower wedge block are provided with convex lines slidingly connected with the chute, and the lower wedge block is provided with positioning slides. The upper wedge is provided with a slider that can extend into the positioning chute and slide relative to the positioning groove. The upper wedge and the lower wedge are provided with movable parts that control the sliding of the upper wedge relative to the lower wedge. The invention has reasonable and simple structure, strong practicability, and strong stability when the upper wedge-shaped block slides relative to the lower wedge-shaped block for detection.

Owner:海盐卡思机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com