Gauge for measuring maximum and minimum values of intervals between rods of internal spline on part

A technology for internal splines and rod spacing, which is applied in the field of gauges for measuring the spacing of internal spline rods on parts. It can solve the problems of many measurement procedures, time-consuming and laborious, etc., and achieve the effects of easy processing accuracy, easy manufacturing, and easy measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

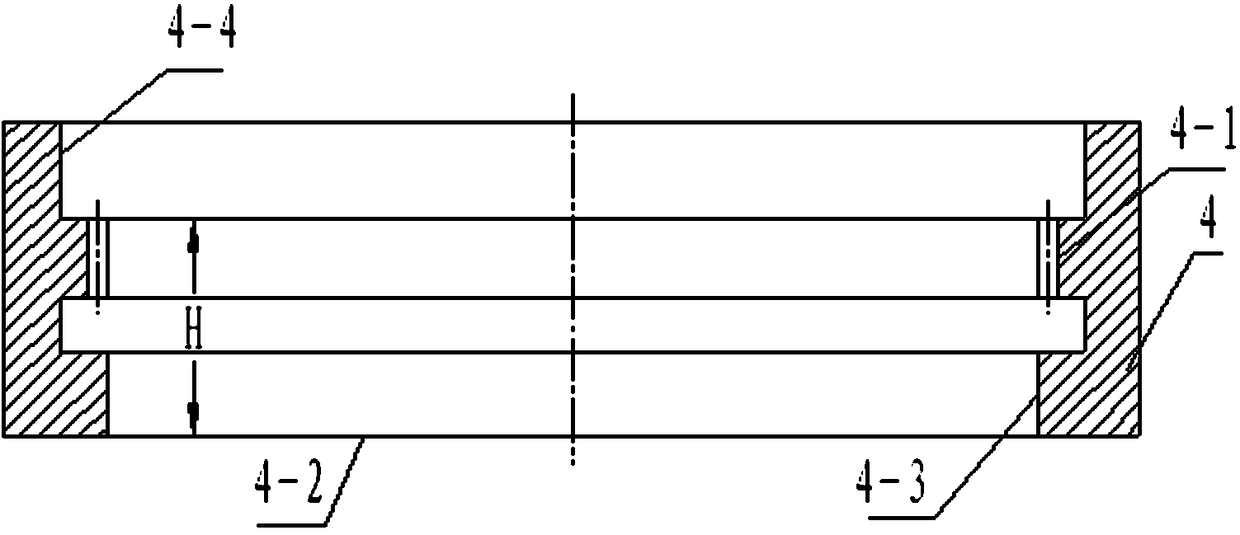

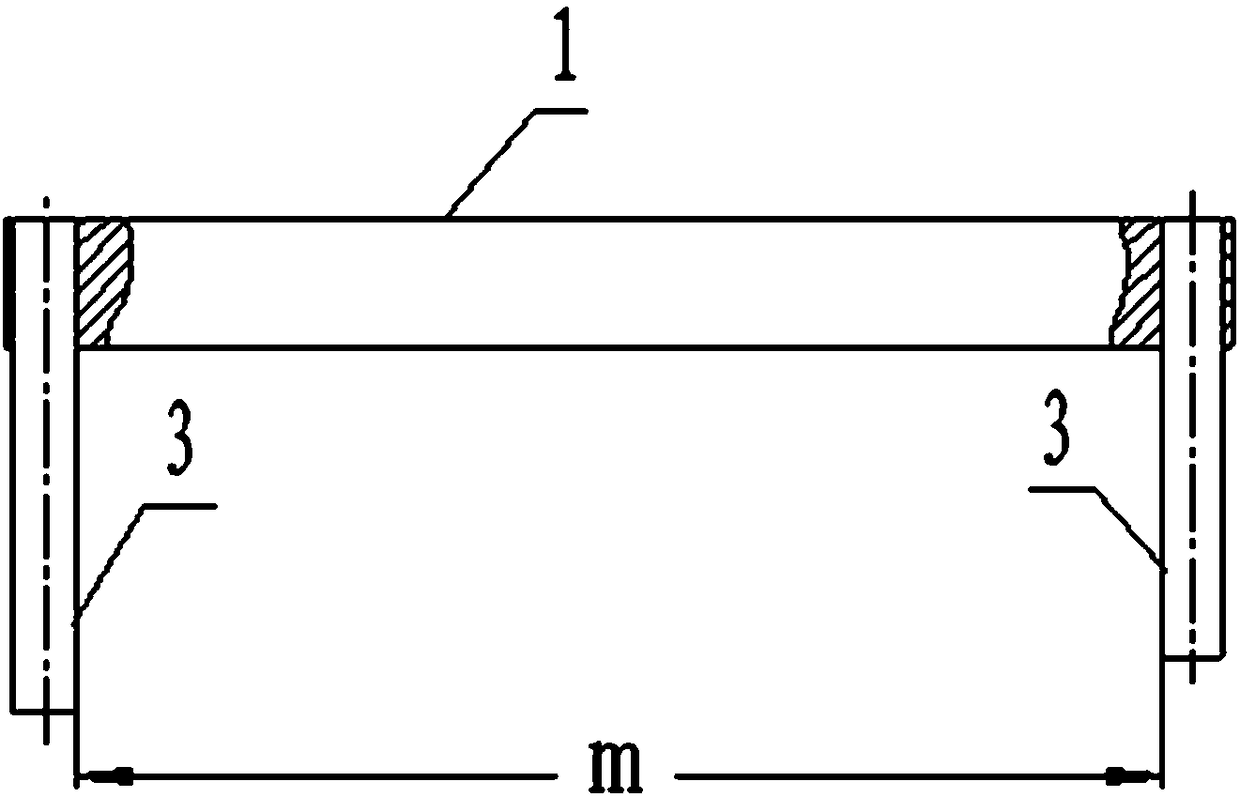

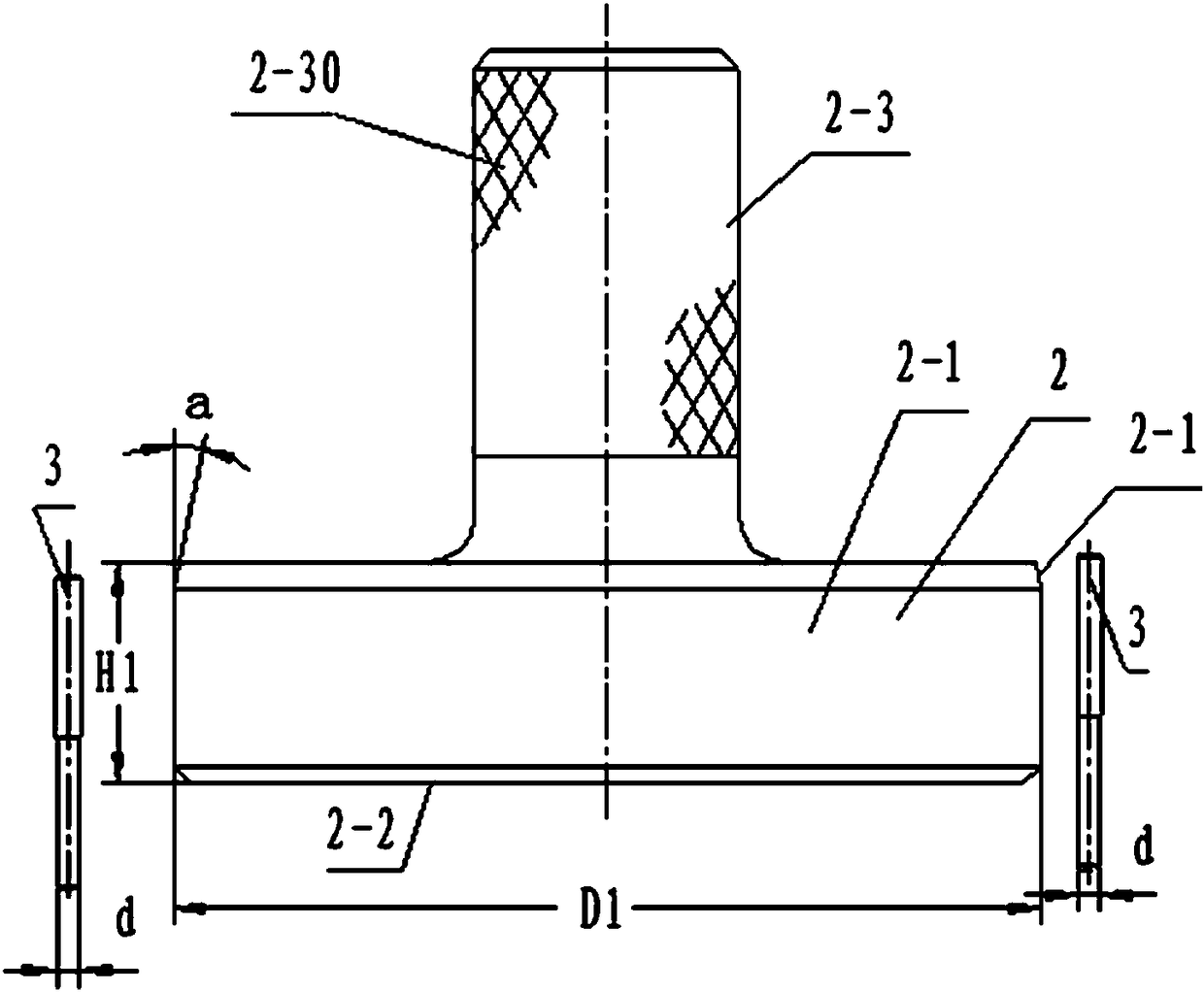

[0031] see image 3 , Figure 4 and Figure 5 , the present invention is a gauge for measuring the maximum distance between internal spline rods on parts, and the internal splines are small modulus involute odd-numbered internal splines. Depend on image 3 , Figure 4 and Figure 5It can be seen that the gauge is a split structure, including a large number of columns 2 and three measuring rods 3 with the diameter d of the measuring rod; The cylinder I2-1 corresponding to the height H from the upper end surface to the lower end surface of the part 4 and the handle I2-3 whose diameter is much smaller than the diameter of the cylinder I2-1 connected to the upper end surface of the cylinder I2-1, said cylinder The diameter ID1 of the body I2-1 corresponds to the maximum value of the rod spacing of the small modulus involute odd-numbered int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com