A device for measuring the arc tooth space width of internal splines

A measuring device and the technology of internal splines, which are applied in the field of measuring instruments, can solve the problems of large measurement error, large repeatability error, unsuitable for mass production inspection, etc., and achieve the effect of avoiding instability and ensuring position positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

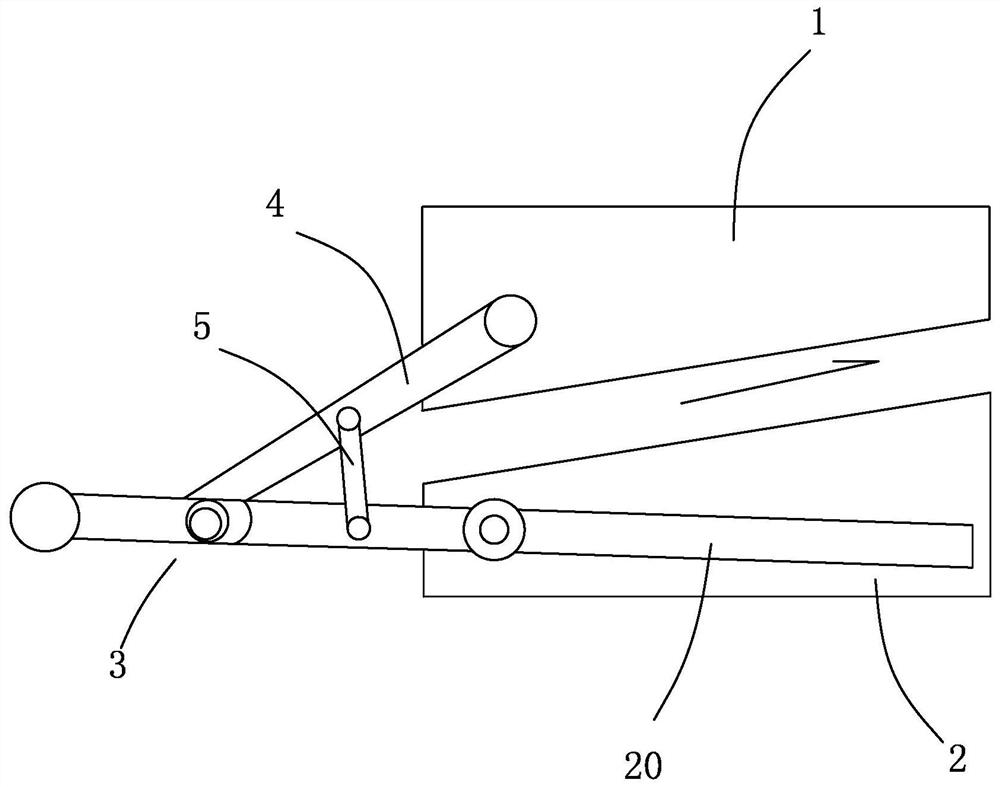

[0022] The first structure of this embodiment: it includes a pair of upper wedge-shaped block 1 and lower wedge-shaped block 2 with a flat bottom and the same inclination angle inclined surface, which are in an up-and-down relationship. slot, and the corresponding two chute slots on the lower wedge block 2 are provided with convex lines that are slidingly connected with the chute slots.

[0023] Movable slots 20 are opened on the corresponding two outer walls of the lower wedge block 2 , and positioning holes are opened on the corresponding two outer walls of the upper wedge block 1 . The upper wedge block 1 and the lower wedge block 2 are provided with movable parts for controlling the sliding of the upper wedge block 1 relative to the lower wedge block 2 .

[0024] The movable part has a sliding column 2a that is slidably connected to the movable groove 20, and the movable part also has a connecting rod 4 that is detachably connected to the positioning hole. The sliding colu...

Embodiment 2

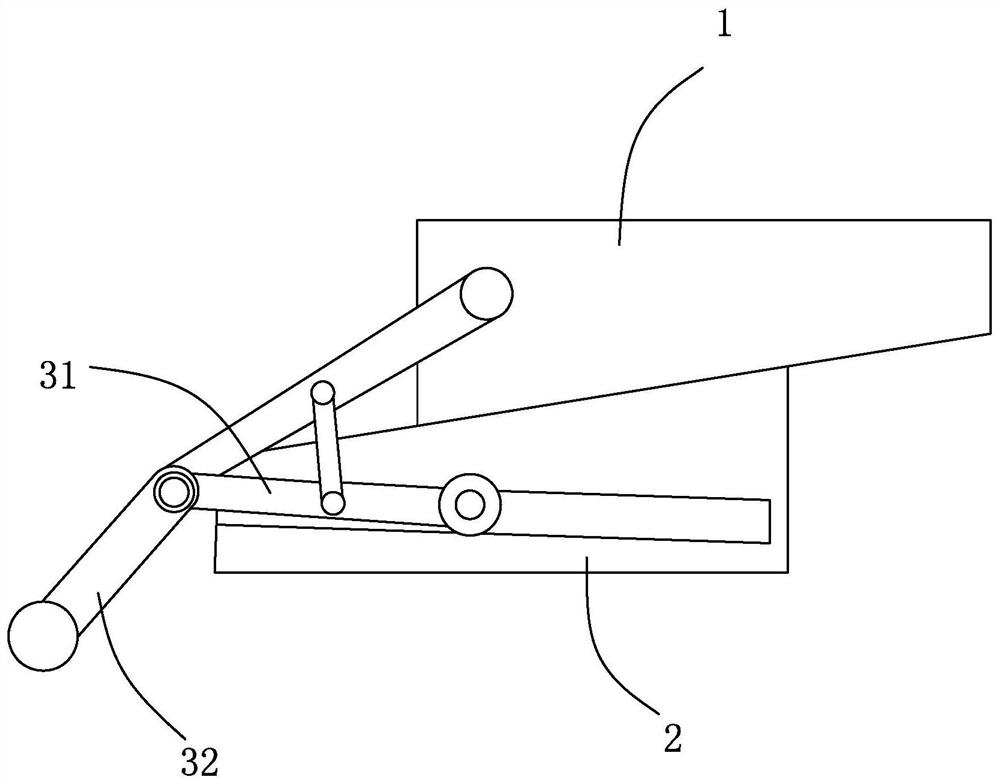

[0030] The second structure of this embodiment:

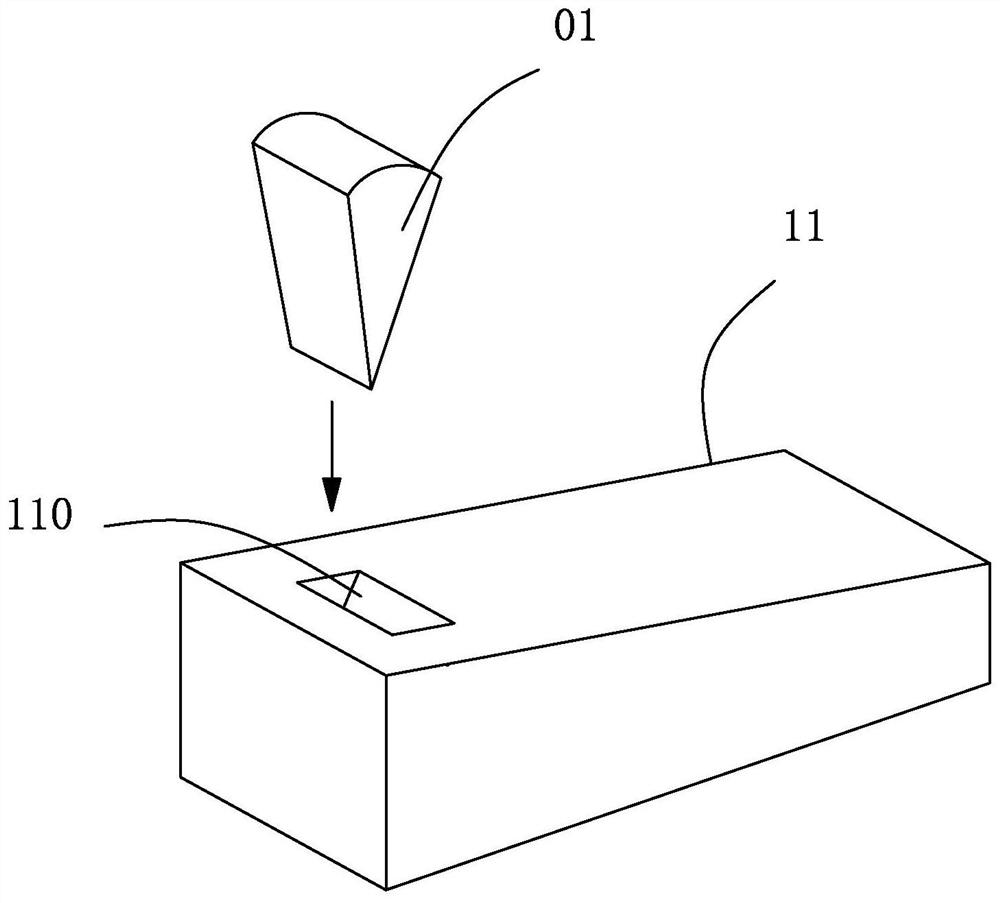

[0031] It includes a pair of upper wedge-shaped block 11 and lower wedge-shaped block 22 with a flat bottom and the same inclination angle. The slope of the upper wedge-shaped block 11 is provided with two corresponding chute 101. Corresponding two chute 101 on 22 are provided with the protruding line 201 that is slidingly connected with chute 101, and lower wedge block 22 is provided with positioning chute 101, and upper wedge block 11 is provided with and can extend in the positioning chute 101, and The slide bar that slides relative to the positioning chute has several positioning gaps on the groove bottom of the chute 101, and the upper wedge block 11 is provided with an opening 110 communicating with the positioning slot, and the positioning pin 01 is inserted on the opening 110, and the upper wedge block When 11 slides relative to the lower wedge block 22 , the end of the positioning pin 01 is inserted into the opening 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com