Detection method for run-out of inner diameter groove

A detection method and runout detection technology, applied in the direction of keyway measurement, measuring devices, mechanical measuring devices, etc., can solve problems such as failure to satisfy customers, increase costs, and fail to meet customer requirements for product delivery cycles, so as to reduce production costs and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

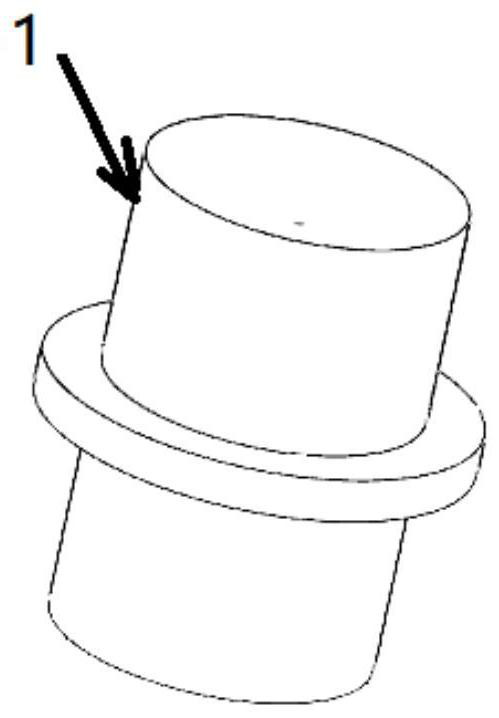

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with the embodiments and accompanying drawings.

[0024] The requirement of the inner diameter groove processed by the present invention is that the runout of the groove diameter φ42.05 to the B reference is 0.2. The runout of the inner diameter groove is generally measured by two circles with three coordinates, and the method of taking points on the circles is used to evaluate the runout of one of the two circles relative to the other. However, the existing three-coordinate system does not have a star probe, so it is impossible to take a point on the circle in the inner diameter groove of the groove diameter φ42.05 for evaluation. Therefore, the present invention provides a detection method for inner diameter groove runout, through Measuring the replacement star probe is done using the existing probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com