A measuring tool and measuring method for wear amount of involute inner spline

An involute and internal spline technology, applied in the field of measuring tools, can solve the problem of low measurement accuracy of the wear amount of the internal spline, and achieve the effects of stable measurement results, high measurement accuracy and stable measurement values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

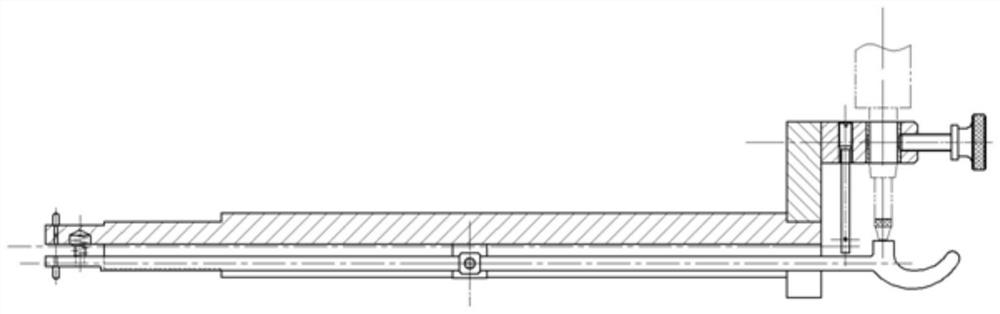

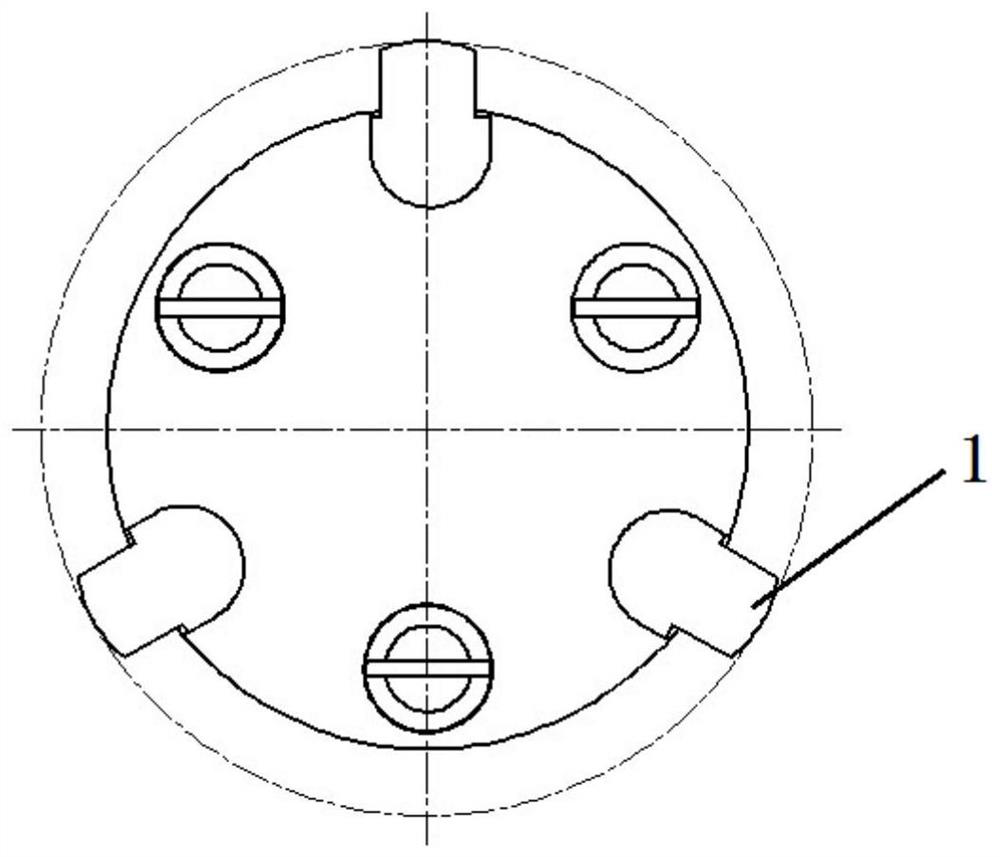

[0061] The measuring tool for the amount of wear of the involute inner spline of this embodiment includes a modified inner diameter micrometer and a standard part;

[0062] The number of teeth of the involute internal spline to be measured is 18, the diameter of the pitch circle is 18, and the modulus is 1. Refer to the "Measuring Tool Design Manual" to obtain the diameter of the rolling rod (measuring rod) dp=Φ1.732, and select the measuring range at Φ19 The left and right digital display three-point inner micrometers, disassemble the measuring heads, and transform the three measuring heads into ball heads with a radius of 0.866. The spherical centers of the ball heads of the three measuring heads are located on the same circumference. The circumference of the measuring head is evenly distributed, which is the modified inner diameter micrometer of this embodiment; the measuring range of the modified inner diameter micrometer is larger than the diameter of the pitch circle of t...

Embodiment 2

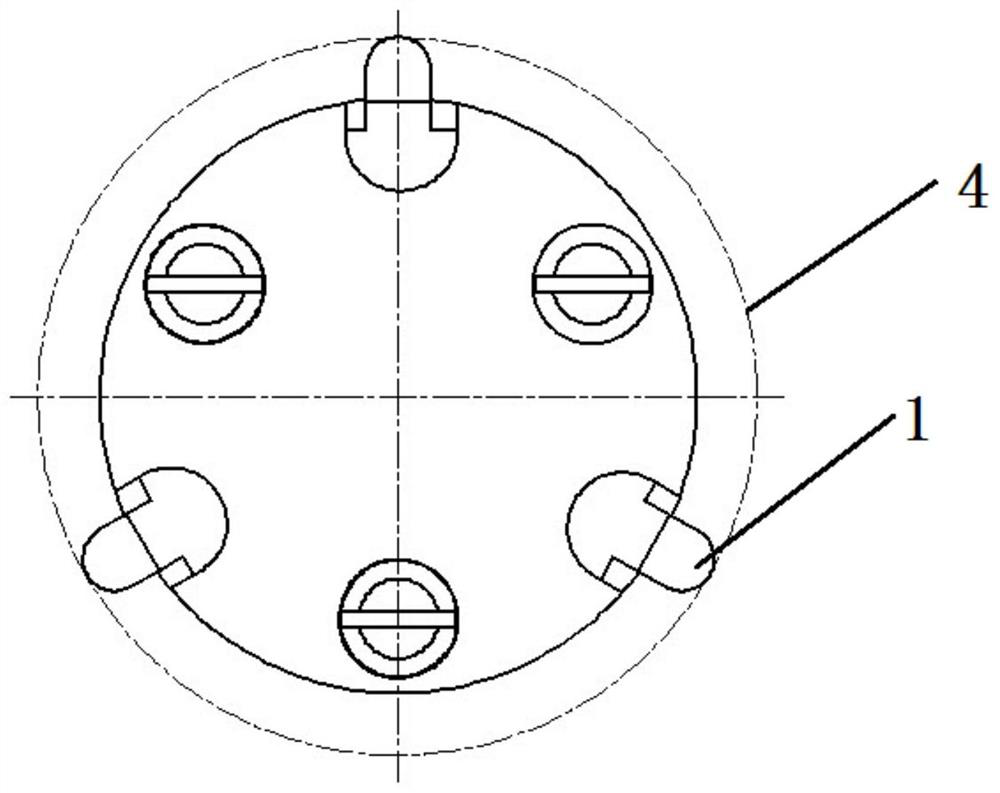

[0069] from Figure 3-7 It can be seen that the measuring tool for the involute inner spline wear amount in this embodiment includes a refitted inner diameter micrometer, standard parts and counter parts;

[0070] The number of teeth of the involute internal spline to be measured is 18, the diameter of the pitch circle is 18, and the modulus is 1. Refer to the "Measuring Tool Design Manual" to obtain the diameter of the rolling rod (measuring rod) dp=Φ1.732, and select the measuring range at Φ19 The left and right digital display three-point inner micrometers, disassemble the measuring heads, and transform the three measuring heads into ball heads with a radius of 0.866. The spherical centers of the ball heads of the three measuring heads are located on the same circumference. The circumference of the measuring head is evenly distributed, which is the modified inner diameter micrometer of this embodiment; the measuring range of the modified inner diameter micrometer is larger ...

Embodiment 3

[0078] The measuring tool for the involute internal spline of this embodiment includes a refitted inner diameter micrometer, standard parts and counter parts;

[0079] The number of teeth of the involute internal spline to be measured is 18, the diameter of the pitch circle is 18, and the modulus is 1. Refer to the "Measuring Tool Design Manual" to obtain the diameter of the rolling rod (measuring rod) dp=Φ1.732, and select the measuring range at Φ19 The left and right digital display three-point inner micrometers, disassemble the measuring heads, and transform the three measuring heads into ball heads with a radius of 0.866. The spherical centers of the ball heads of the three measuring heads are located on the same circumference. The circumference of the measuring head is evenly distributed, which is the modified inner diameter micrometer of this embodiment; the measuring range of the modified inner diameter micrometer is larger than the diameter of the pitch circle of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com