Keyboard bottom plate automatic detection device

An automatic detection device and bottom plate technology, which is applied in the detection field, can solve the problems of low accuracy and low efficiency of manual detection of the keyboard bottom plate, and achieve the effects of high accuracy, prevent accuracy, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

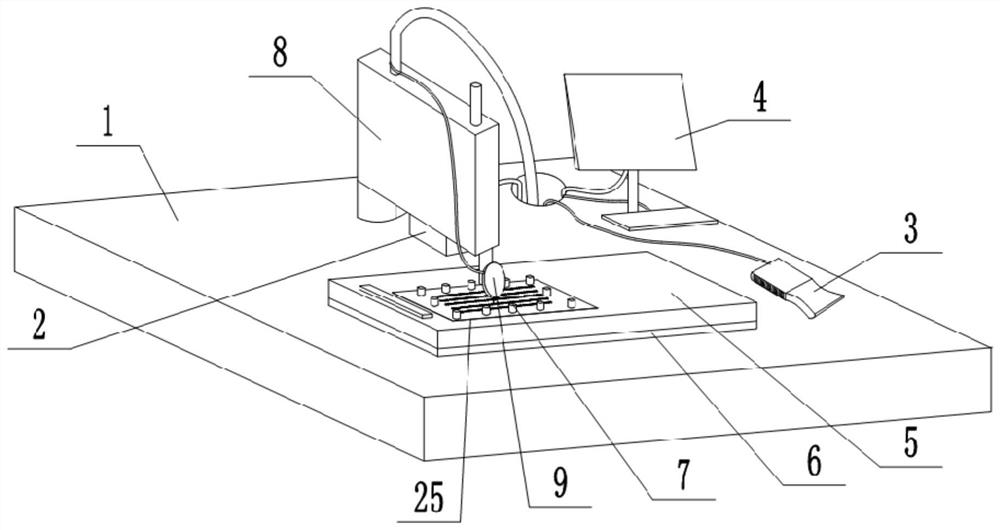

[0034] Keyboard bottom plate 25 automatic detection device, as attached figure 1 As shown, it is mainly composed of a workbench 1, a mounting base 2, a teaching pendant 3, a computer 4, a detection table 5, a manipulator 8, a digital indicator 9, an electromagnet 6, and several limit blocks 7. The mounting base 2 is installed on the rear side of the workbench 1, and the manipulator 8 is rotatably connected to the mounting base 2. The teaching pendant 3 is placed on the workbench 1 , and the teaching pendant 3 is connected with the manipulator 8 for setting programming to control the motion trajectory of the manipulator 8 . The computer 4 is installed on the rear side of the workbench 1, the digital display dial indicator 9 is installed at the bottom of the manipulator 8, the digital display dial indicator 9 is connected with the computer 4, and the read data is transmitted to the computer 4 and passed through The display of computer 4 shows, reads and calculates for operating...

Embodiment 2

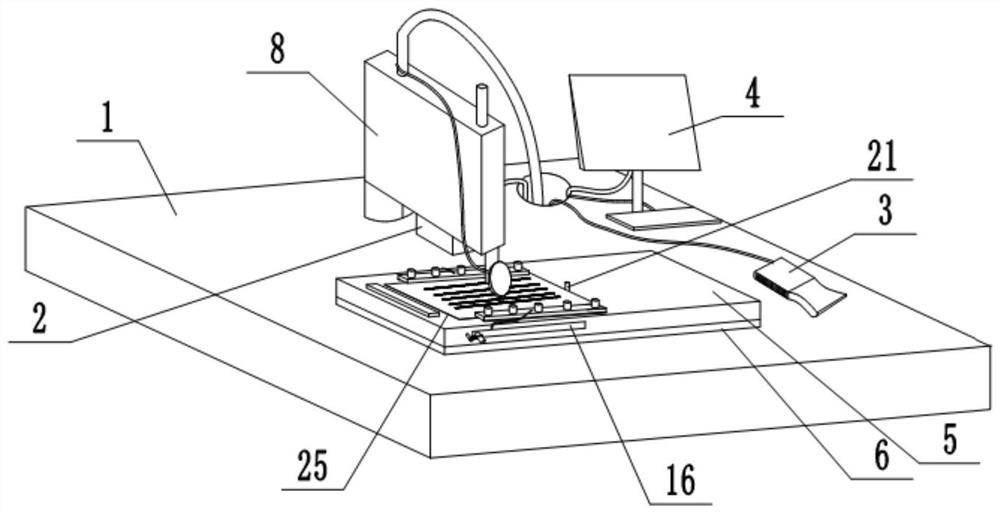

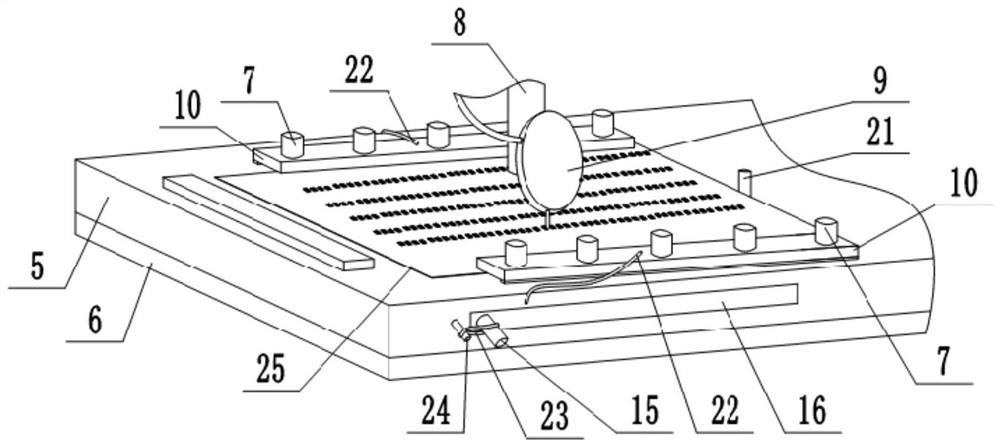

[0039] The difference between this embodiment and embodiment 1 is: as attached figure 2 , attached image 3 And attached Figure 4As shown, the front side and the rear side of the detection platform 5 are also hinged with a pressing plate 10, the pressing plate 10 is made of a material that can be attracted by the electromagnet 6, preferably iron; the bottom of the pressing plate 10 is provided with a buffer layer. Several limit blocks 7 are evenly distributed on the two pressing plates 10, and the electromagnet 6 can pass through the detection table 5 to attract the pressing plates 10 and the limiting blocks 7 when the electromagnet 6 generates magnetism; Cooperate, on the one hand can increase the contact area of keyboard bottom plate 25 and pressing down part (pressing down part in the present embodiment refers to the parts that keyboard bottom plate 25 is pushed down, as pressing plate 10, limit block 7), makes the bottom of keyboard be affected. The force is more bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com