Movable workbench V-groove inspection tool and inspection method thereof

A technology for moving workbenches and inspection tools, which is applied in the direction of instruments, measuring devices, mechanical measuring devices, etc. It can solve the problems of inconvenient operation by one person, time-consuming and labor-intensive, etc., and achieve the effect of convenient measurement, convenient use and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

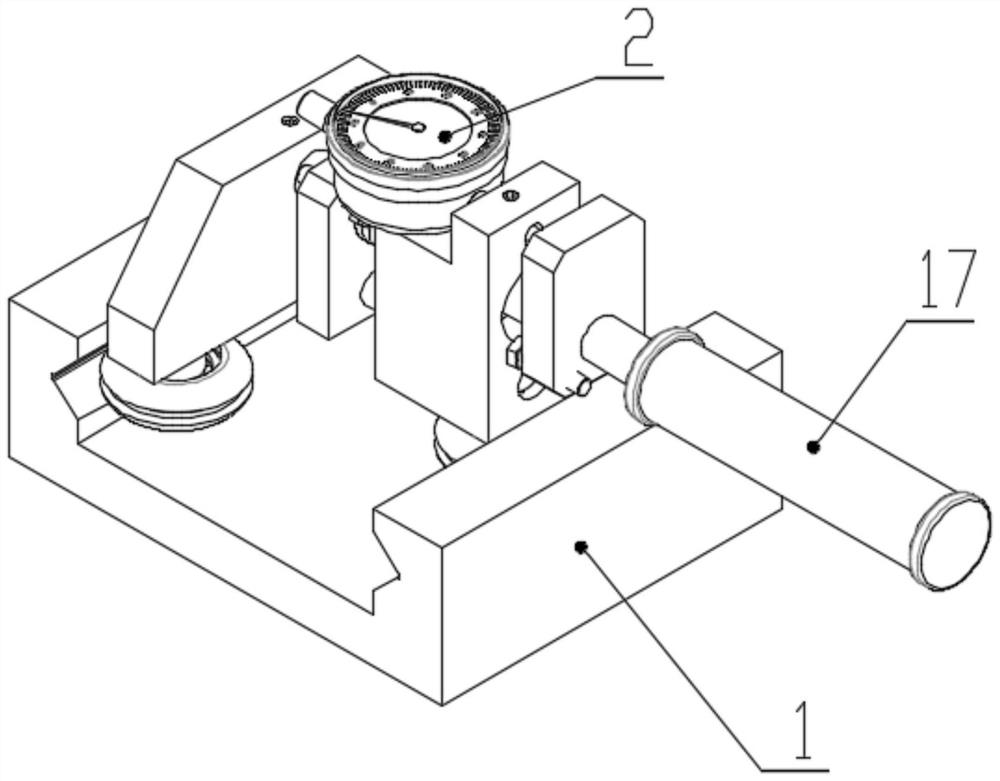

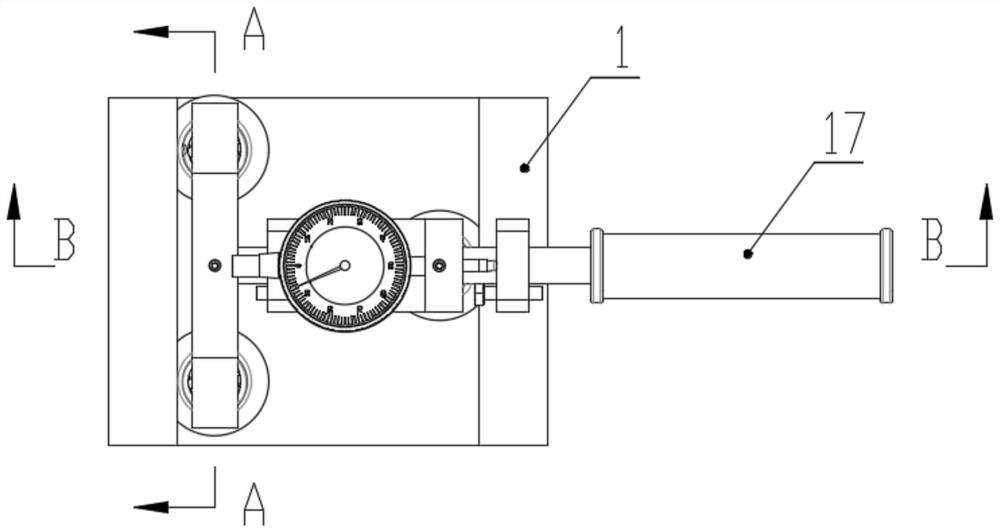

[0032] The present invention provides a V-groove inspection tool for a mobile workbench, see figure 1 and Figure 7 , the mobile workbench V-groove inspection tool uses the V-shaped groove of the V-shaped sample block 1 to adjust and calibrate the value, and move the calibrated mobile workbench V-groove inspection tool to the processed mobile workbench aluminum profile 19 (The V-shaped groove on the aluminum profile 19 of the mobile worktable is processed according to the size of the V-shaped groove of the V-shaped sample block 1), and measure whether the V-shaped groove on the aluminum profile 19 of the mobile worktable meets the inspection requirements. If the inspection result of the V-shaped groove on the aluminum profile 19 is within a reasonable error range, it is judged as a qualified product. If it exceeds the reasonable error range, the aluminum profile 19 of the mobile workbench needs to be reprocessed or directly scrapped.

[0033] The V-shaped sample block 1 is m...

Embodiment 2

[0046] The present application also provides a method for inspecting the V-groove of the mobile workbench, comprising the following steps:

[0047] Step 1, make V-shaped sample block 1.

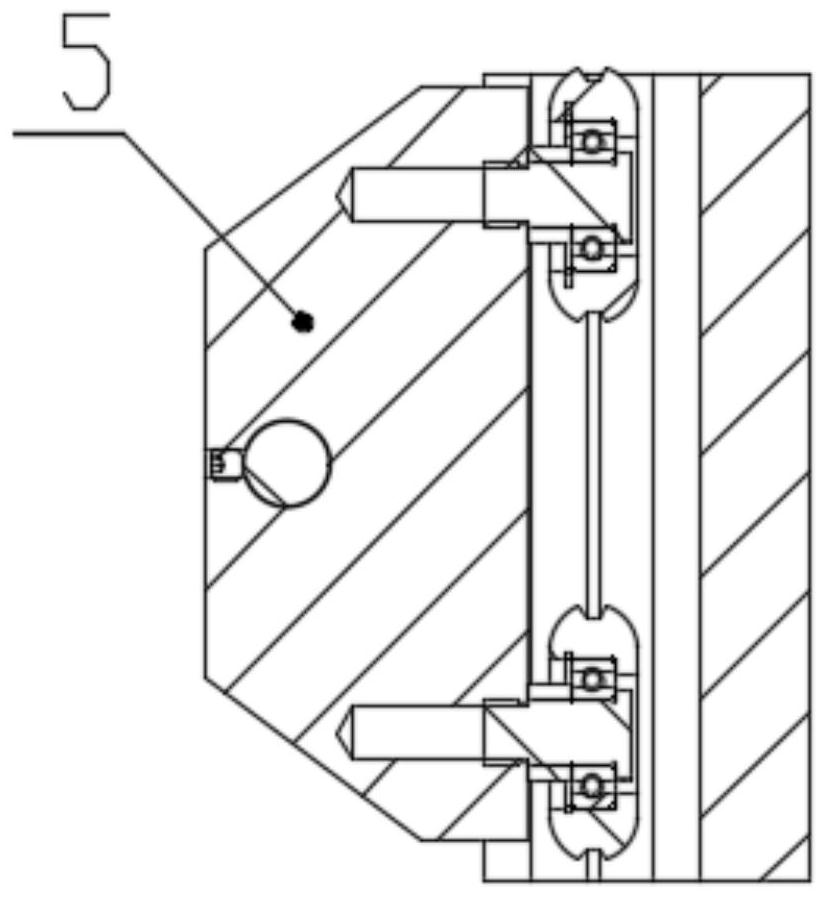

[0048] Step 2: Adjust the V-groove inspection tool of the mobile worktable according to the V-shaped sample block 1. Specifically, adjust the positions of the fixed plate 5, the front positioning plate 13, the floating table base 9 and the rear positioning plate 16 on the positioning shaft 6, so that the floating table The grooved roller 3 at the bottom of the seat 9 and the fixed plate 5 is located in the V-shaped groove of the V-shaped sample block 1 .

[0049] Step 3: Move the V-groove inspection tool of the worktable to adjust and calibrate the value by using the V-groove of the V-shaped sample block 1 .

[0050] Step 4: Move the V-groove inspection tool of the mobile worktable after calibration to the processed aluminum profile 19 of the mobile worktable to verify whether the V-groove on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com