Improved battery separators, batteries and related methods

A battery separator and battery technology, applied in lead-acid battery electrodes, lead-acid batteries, battery pack components, etc., can solve the problems of inability to improve rechargeability, inability to improve the charge acceptance of industrial batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

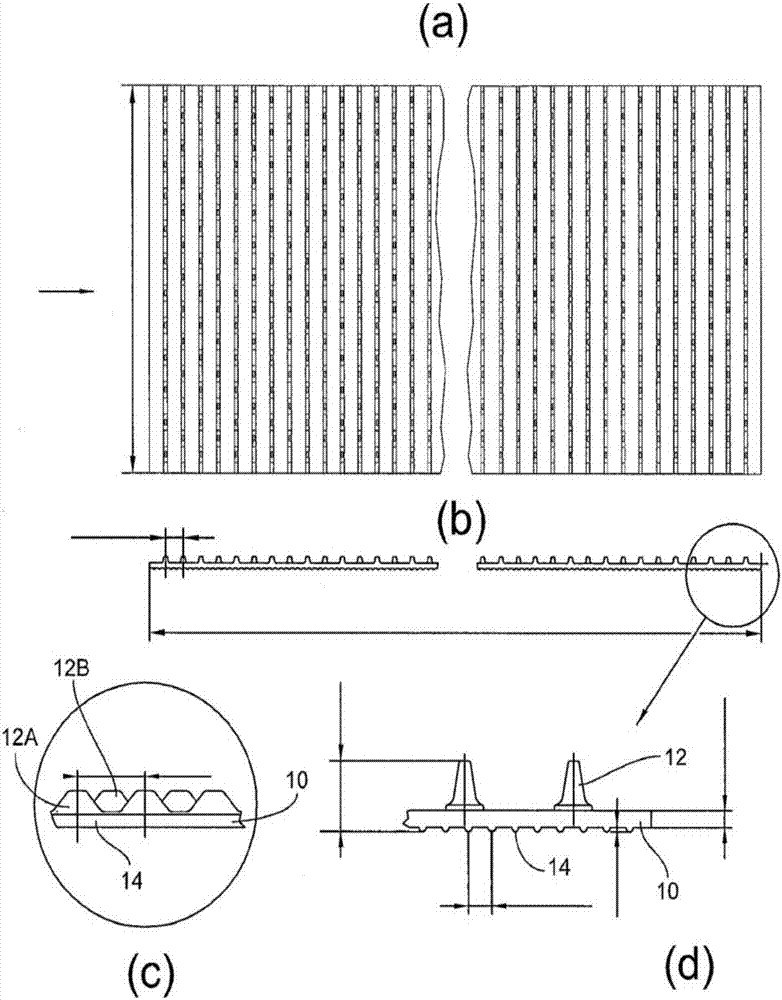

[0056] In Example 1, it was made according to image 3 The physical type of spacer shown. Photographs were taken of the clapboard, shown in figure 1 and figure 2 .

Embodiment 2

[0058] In Example 2, several cells were constructed and tested to determine how well the improved separator according to the present invention would function. The batteries used were tubular flooded inverter batteries, commercially available from Aegan Batteries, Bangalore, India. The battery tested was 12V100Ah at 20 hours. The number of plates per unit is 9 (4 positive, 5 negative). The antimony content in the grid is 2.5%. The average dry plate weight for the positive plates was 474.5 grams, and the average dry plate weight for the negative plates was 336 grams. The weight of the positive plate group is 1898+ / -2 grams / unit; the weight of the negative plate group is 1680+ / -1 grams / unit.

[0059] For the experimental cells, the separator used was a backplate thickness of about 400 microns, an overall thickness of about 1.6 mm and according to image 3 Coated polyethylene separator with zigzag profile. This experimental separator was coated with surfactant coatings at two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com