Drawer type goods shelf sorting system for multilayer shuttling warehouse

A sorting system and drawer-type technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of large area occupied by goods storage, low picking efficiency, and untimely replenishment, so as to improve production efficiency, save labor costs, The effect of reducing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

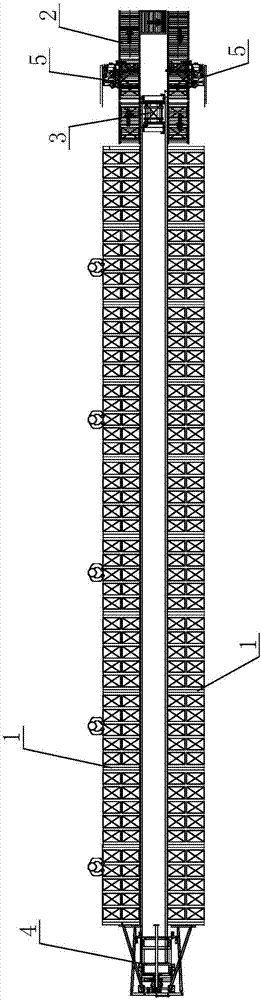

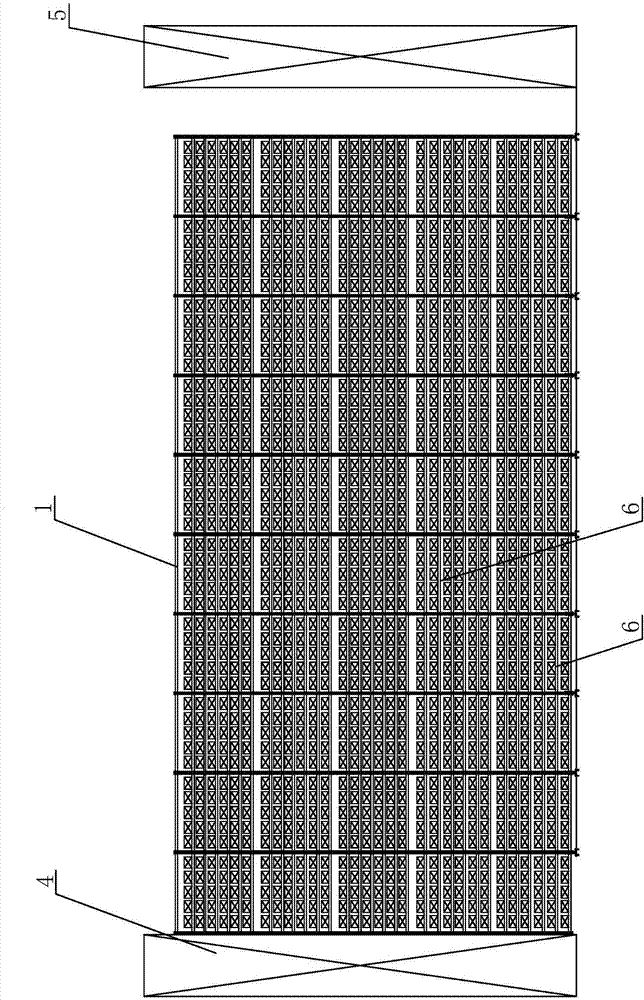

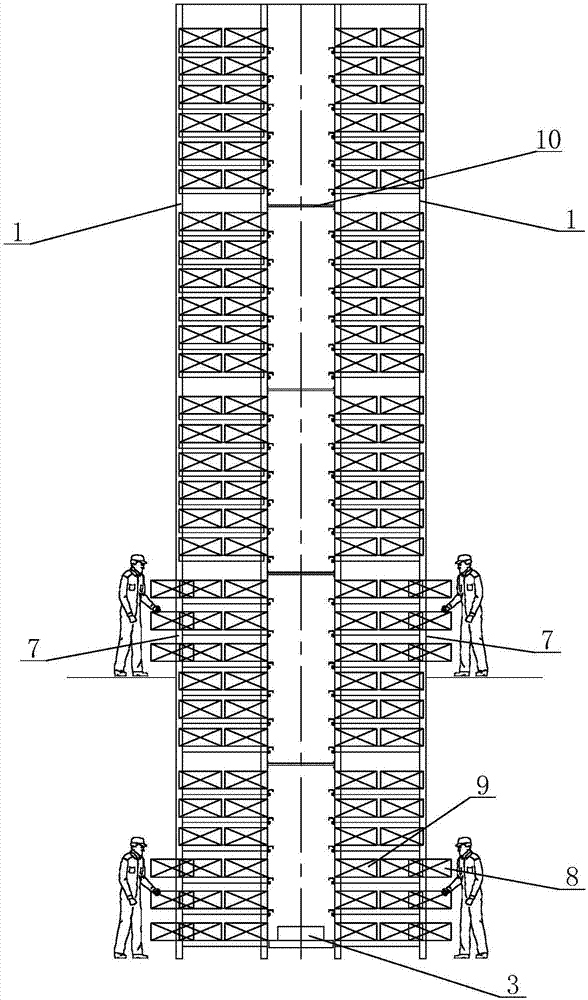

[0014] see Figure 1 to Figure 3 As shown, in this embodiment, a drawer-type shelf sorting system for a multi-layer shuttle warehouse includes two multi-shuttle warehouse shelves 1, an automatic conveying line 2, a shuttle trolley 3, a shuttle trolley layer-changing elevator 4, and a goods Elevator 5 and automatic control system, the shuttle trolley 3 is arranged between two multi-pass warehouse shelves 1, one end of the multi-pass warehouse shelf 1 is provided with a cargo elevator 5 and an automatic conveying line 2, and the other end is provided with a shuttle trolley A layer-changing hoist 4, a shelf picking position 6 is provided on the outer side of the bottom of the multi-pass warehouse shelf 1, and a slide rail is installed on the shelf picking position 6, and the turnover box can be pulled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com