Beam bubbler

A bubbler and integrated technology, applied in the field of faucets or showers, can solve the problems of user discomfort, reduced sealing performance, and increased material waste, so as to save installation and maintenance time, ensure sealing performance, and solve labor problems. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

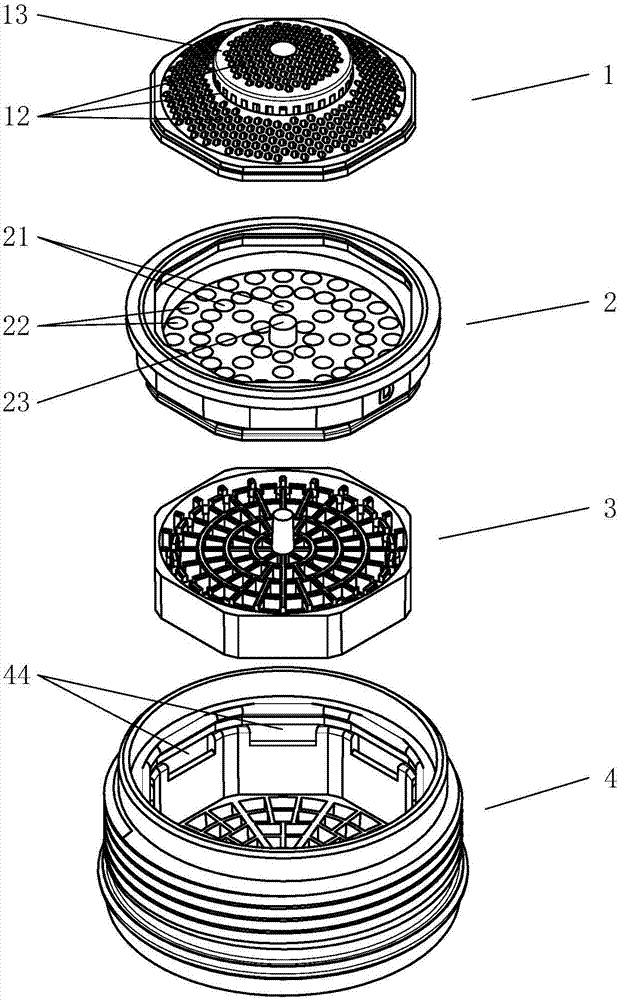

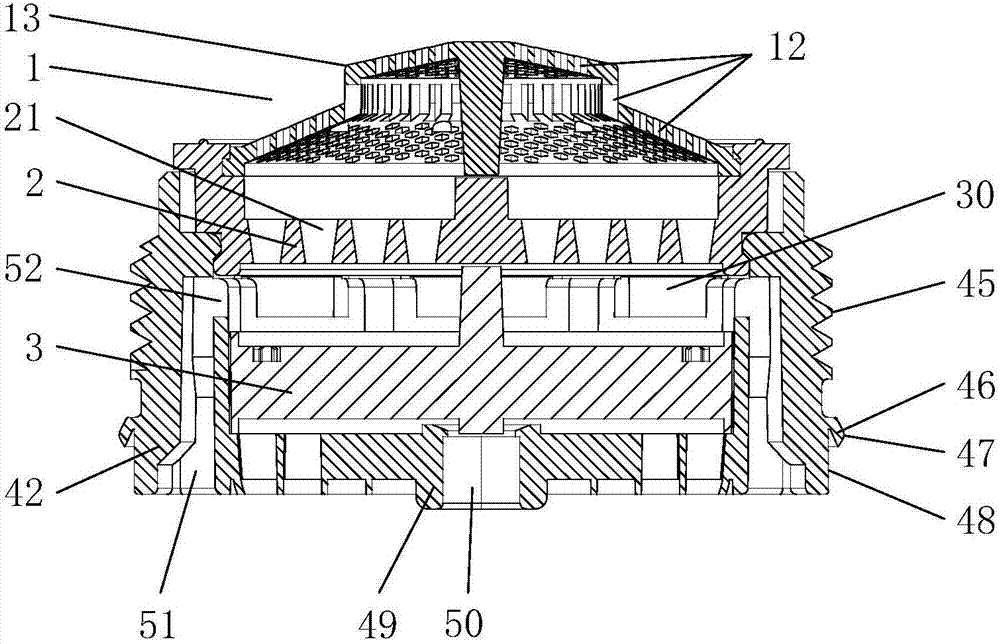

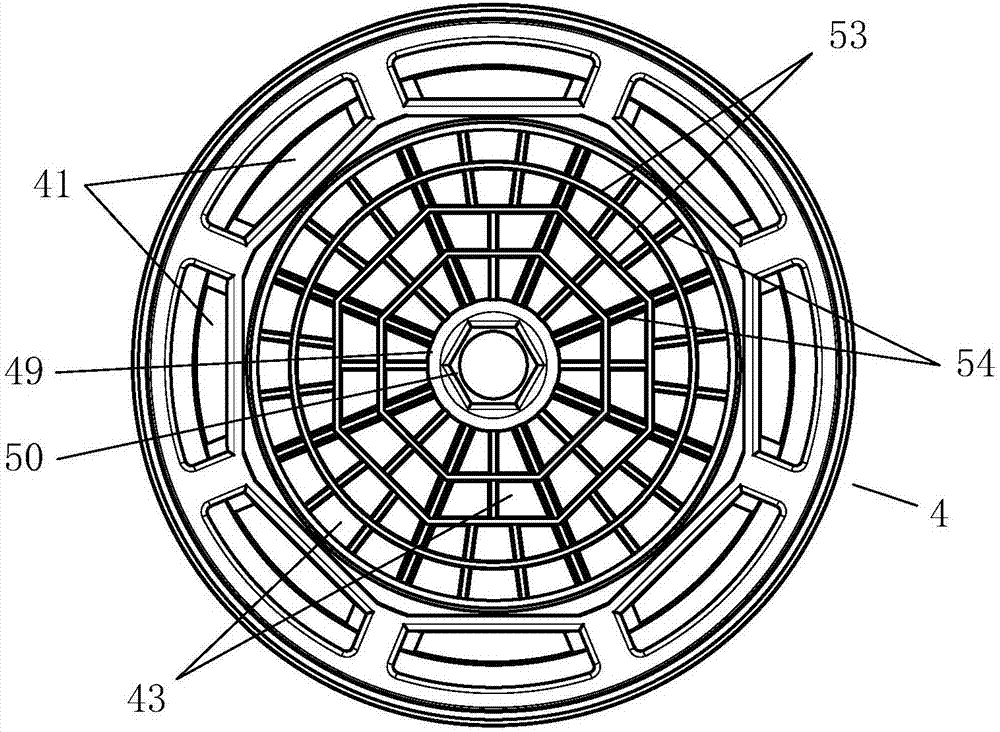

[0027] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 8 :

[0028] A jet bubbler, comprising a shell 4 with several water outlet holes 43 arranged on the lower bottom, foaming inserts 3 and rectifiers 2 are arranged at intervals in the shell 4 from bottom to top, and a filter element 1 is connected to the upper end of the rectifier 2 An external thread 45 is integrally formed with the shell 4 on the outer wall 48 of the shell 4 , and an elastic sealing lip 46 is formed integrally with the shell 4 on the outer wall 48 of the shell 4 below the external thread 45 .

[0029] The above-mentioned sealing lip 46 extends outward from the outer wall 48 of the housing 4 and slopes downward to form a cantilever. The outer surface of the cantilever is an arc-shaped sealing surface 47 protruding outward.

[0030] The middle part of the lower bottom of the above-mentioned housing 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com