Electric feeding machine

A feeder and electric technology, which is applied in the field of feeders for building secondary structural column pouring machines, can solve the problems of complicated transportation procedures, limited use, large volume, etc., and achieves simple transportation procedures, increased stability, and reduced volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

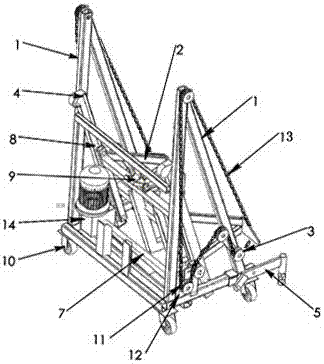

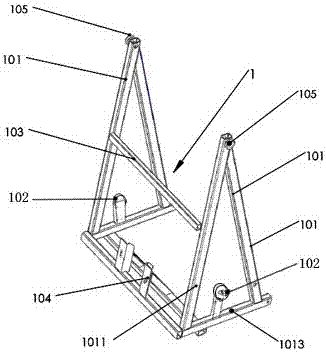

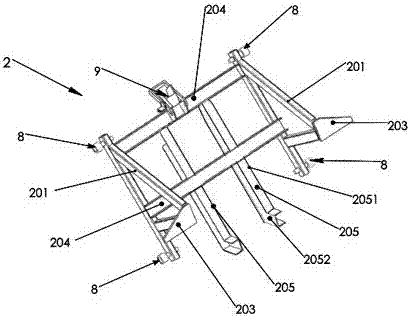

[0028] Such as figure 1 , figure 2 , Image 6 As shown, an electric feeding machine includes a synchronous shaft (7), a guide wheel (8), a lock (9), a driving sprocket (11), a flange (12), a chain (13), a driving device ( 14), the main frame (1), the lifting trolley (2) and the guide rail (4), wherein the main frame (1) includes two side frames (101) and the main frame beam connecting the two side frames (101) (103), side frame (101) is triangular structure, is made up of diagonal brace one (1011), diagonal brace two (1012) and bottom beam (1013), and guide sprocket wheel one (105) is installed on the outside of side frame (101) ) and guide sprocket four (102), and guide sprocket one (105) is at the top position of the side frame (101); there are two guide rails (4), whose cross-section is "凵" type, consisting of inclined rails ( 402) and the flat rail (403) are composed of two parts, the side is "ヘ" type, the guide rail (4) is respectively connected with the diagonal brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com