Push-up system for heavy loads

A heavy-duty, heavy-duty technology, applied in the field of push-up systems for heavy loads, can solve the problems of easy failure, expensive, difficult to replace lifting modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] When the same reference numerals are used in the drawings, these reference numerals denote the same parts.

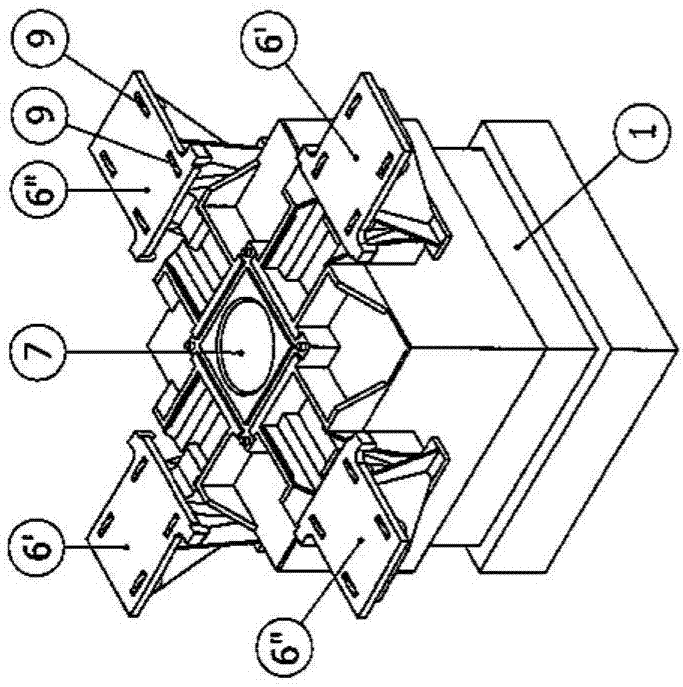

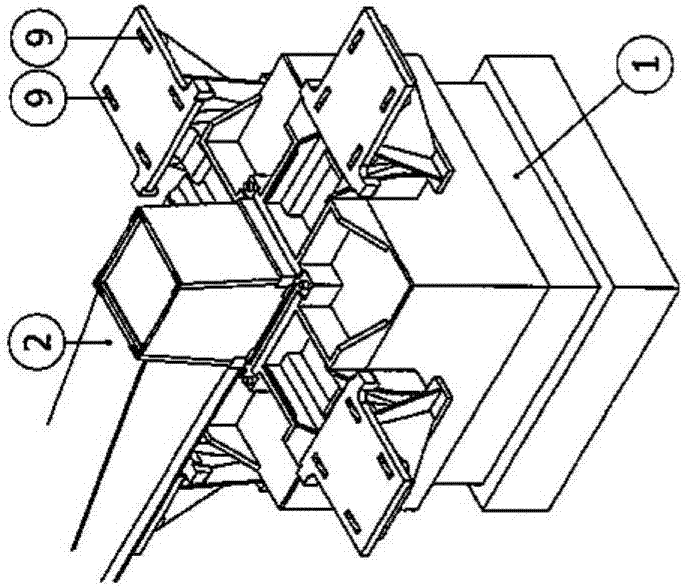

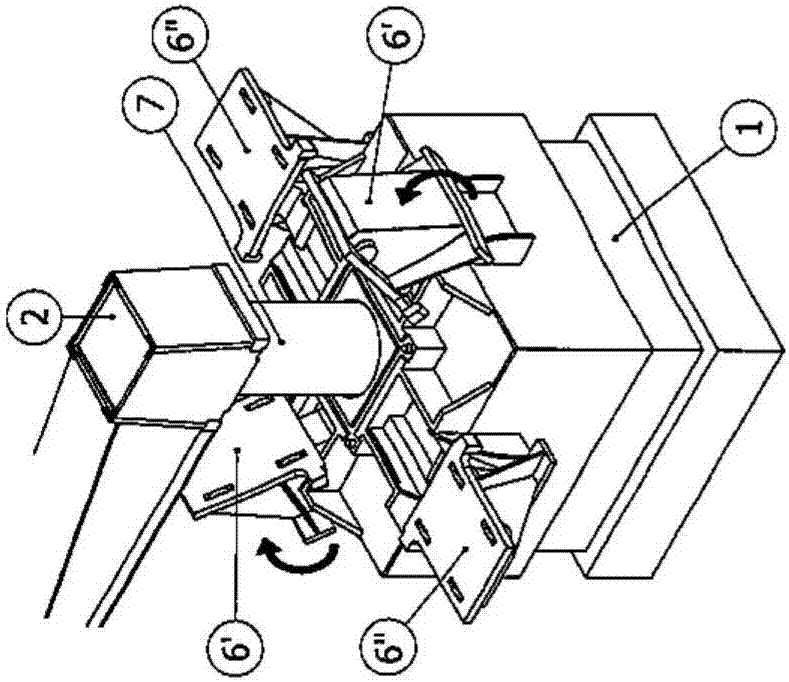

[0025] first reference Figure 11 and 12 , the push-up system of the present invention is shown in a rectangular configuration. exist Figure 11 Four lifting modules 1 are used in the Figure 12 Six lifting modules 1 are used in the system. In a manner known per se from Dutch patent 1037817, for raising or lowering the load, the support beams 2 are arranged staggeredly in or removed from the stack of load-carrying support beams 2, wherein the support beams 2 are in a first direction and are disposed on top of each other in a second direction transverse to the first direction. For example, a support beam 2 arranged in a first direction is supported or removed using a roller track 4 shown on the left side of the figure, while a support beam 2 arranged in a second direction is supported or removed using a roller track 4 shown on the right side of the figure 4 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap