β-k 2 so 4 Structured orthophosphate scintillator material and its preparation method and application

A-K2SO4, scintillator material technology, applied in luminescent materials, analytical materials, fluorescence/phosphorescence, etc., can solve the problems of low luminous efficiency, low cost, short afterglow, etc., achieve short luminous life, improve absorption effect, structure and Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

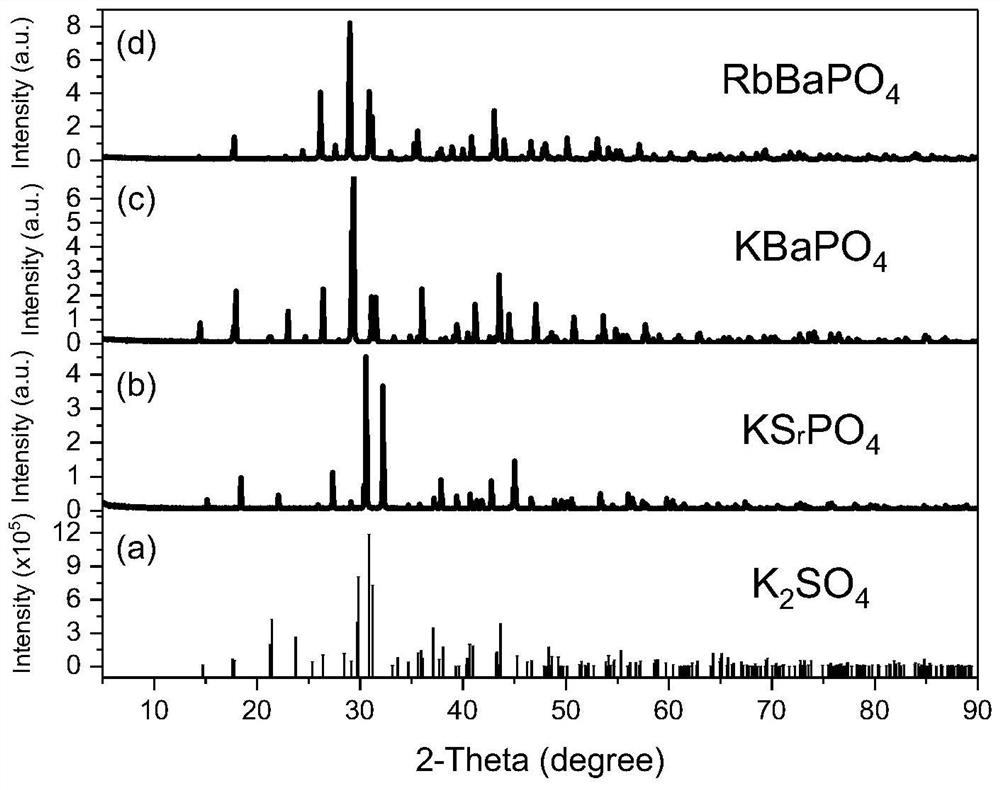

Embodiment 1

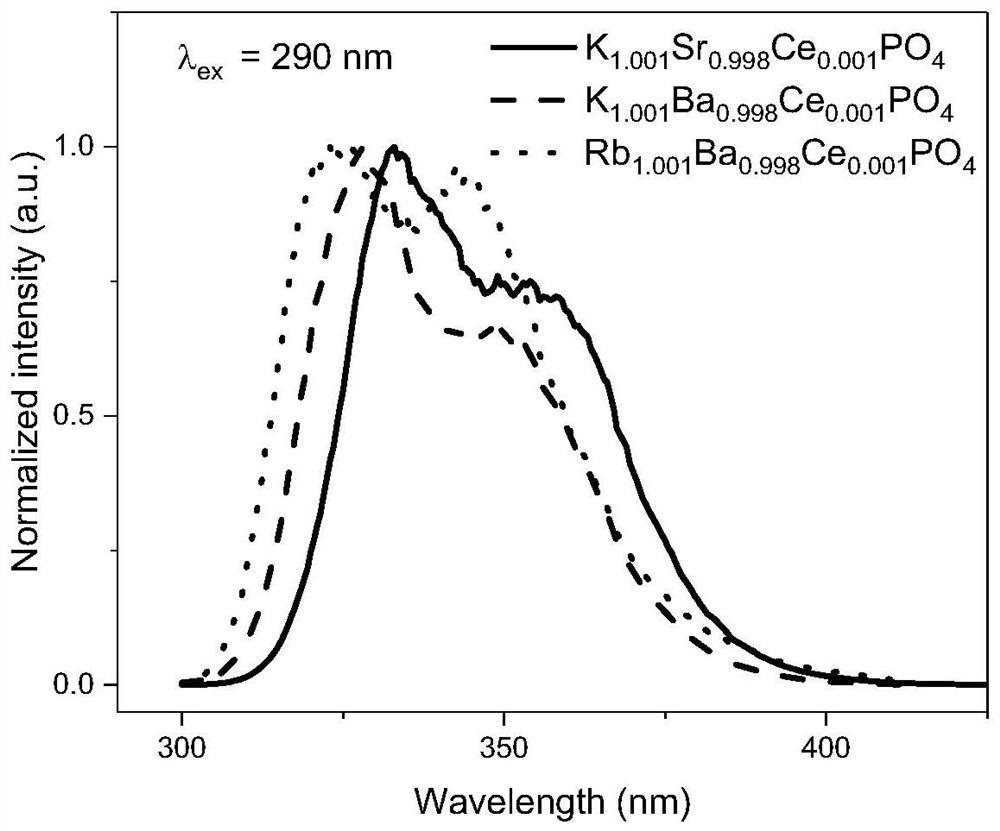

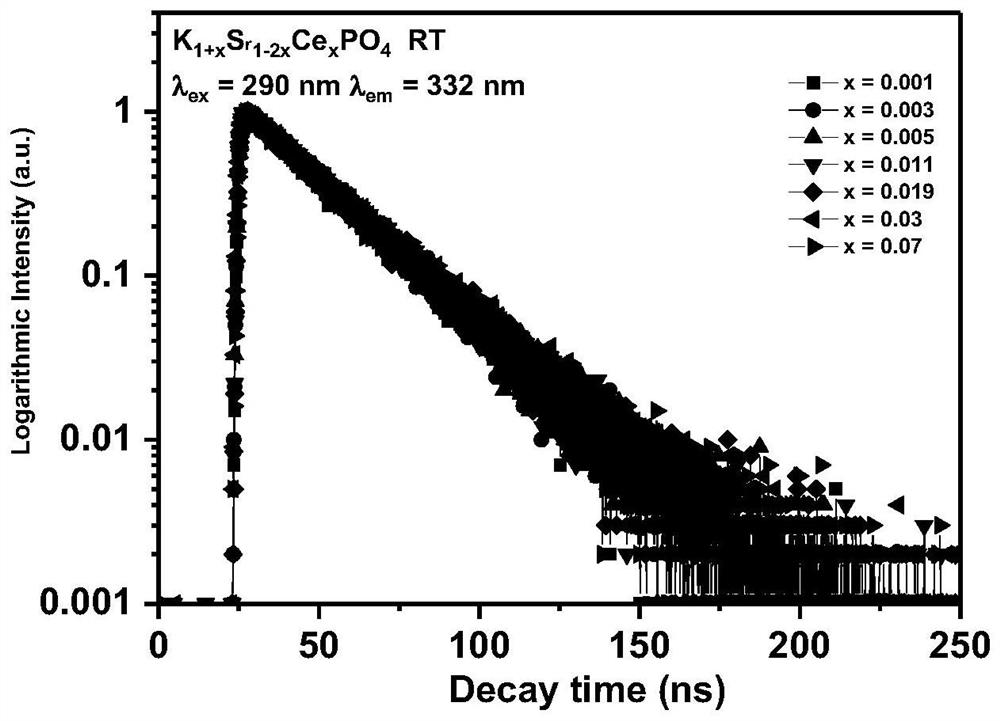

[0043] Weigh potassium dihydrogen phosphate (KH 2 PO 4 ) 0.6905 g, strontium carbonate (SrCO 3 ) 0.7367 g, potassium carbonate (K 2 CO 3 ) 0.003 g and ceria (CeO 2 ) 0.0009 g in an agate mortar and grind for 20 minutes to mix evenly, then put it into a corundum crucible, put the corundum crucible into a large corundum crucible with a carbon block, and roast the reaction at a high temperature in a CO reducing atmosphere. The specific heating procedure is as follows : Take 5 hours to raise the temperature from room temperature to 1300°C, and keep it warm for 3 hours; wait for the sample to cool naturally to room temperature to obtain the final product, and its chemical composition expression is K 1.001 Sr 0.998 Ce 0.001 PO 4 .

Embodiment 2

[0045] Weigh potassium dihydrogen phosphate (KH 2 PO 4 ) 0.6905 g, barium carbonate (BaCO 3 ) 0.9847 g, potassium carbonate (K 2 CO 3 ) 0.003 g and ceria (CeO 2 ) 0.0009 g in an agate mortar and grind for 20 minutes to mix evenly, then put it into a corundum crucible, put the corundum crucible into a large corundum crucible with a carbon block, and roast the reaction at a high temperature in a CO reducing atmosphere. The specific heating procedure is as follows : Take 5 hours to raise the temperature from room temperature to 1300°C, and keep it warm for 3 hours; wait for the sample to cool naturally to room temperature to obtain the final product, and its chemical composition expression is K 1.001 Ba 0.998 Ce 0.001 PO 4 .

Embodiment 3

[0047] Weigh diammonium hydrogen phosphate ((NH 3 ) 2 HPO 4 ) 0.5582 g, barium carbonate (BaCO 3 ) 0.7878 g, rubidium carbonate (Rb 2 CO 3 ) 0.4904 g and ceria (CeO 2 ) 0.007 g in an agate mortar and ground for 20 min to mix evenly, then put it into a corundum crucible, put the corundum crucible into a large corundum crucible with a carbon block, and roast it at a high temperature in a CO reducing atmosphere. The specific heating procedure is as follows : It takes 4 hours to raise the temperature from room temperature to 1000°C, and keep it warm for 6 hours; after the sample is naturally cooled to room temperature, the final product is obtained, and its chemical composition expression is Rb 1.001 Ba 0.998 Ce 0.001 PO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com