A kind of high-strength corrosion-resistant aluminum alloy and preparation method thereof

A corrosion-resistant aluminum alloy and aluminum alloy technology, applied in the field of metal material engineering, can solve problems such as failure, and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

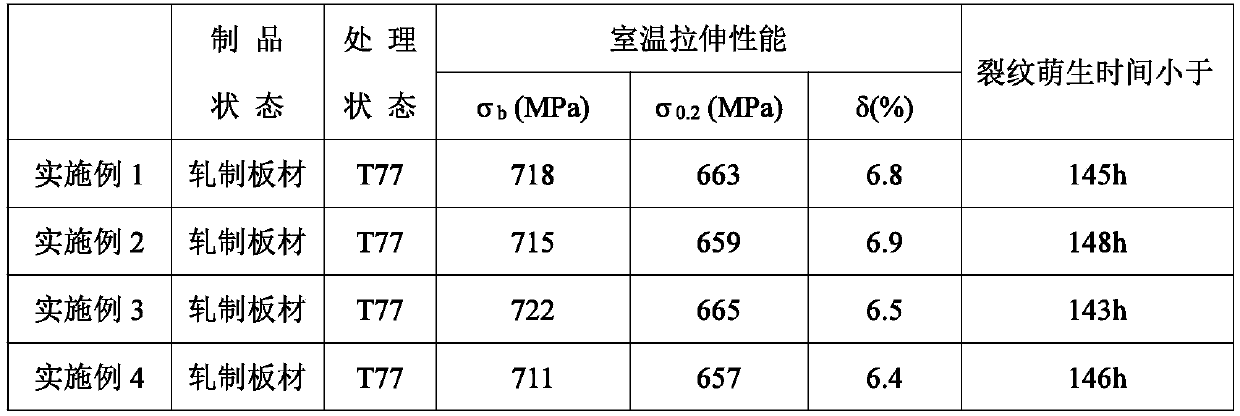

Examples

Embodiment 1

[0034] A high-strength corrosion-resistant aluminum alloy, the composition and weight percentage of the aluminum alloy are: 10.12% Zn, 2.04% Mg, 2.10% Cu, 0.12% Zr, 0.08% Ce, 0.035% Fe, Si It is 0.032%, and the balance is Al and other impurities whose content is less than 0.05%.

[0035] The preparation method of the high-strength corrosion-resistant aluminum alloy of the present embodiment comprises the following steps:

[0036] (1) Add aluminum, zinc, copper source, zirconium source and cerium source to the smelting furnace in sequence according to the ratio and smelt at 770°C. After complete melting, go through argon degassing treatment, and then add magnesium (including the amount of burning loss, burning The amount of loss is 3% of the added amount of magnesium), and after complete melting, the molten alloy is obtained by argon degassing again, and left to stand for 1 hour; wherein, aluminum is high-purity aluminum with an aluminum content of 99.95%, zinc is pure zinc, an...

Embodiment 2-4

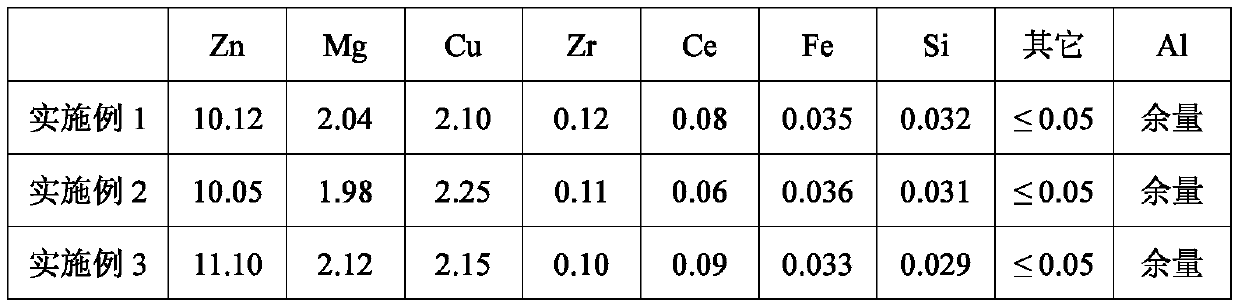

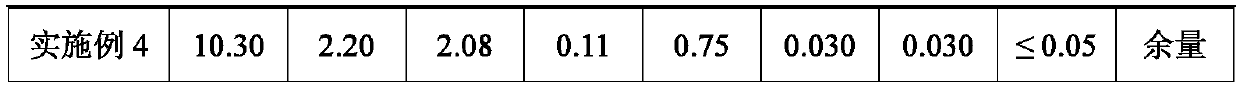

[0044] The composition and preparation method of the high-strength corrosion-resistant aluminum alloy in Examples 2-4 are the same as those in Example 1, but the parts by weight of each component in the composition are different. See Table 2 for specific data.

[0045] Table 2: Parts by weight (weight percent wt%) of aluminum alloy components in the examples

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com