Stop valve with quite high safety performance

A safety performance, cut-off valve technology, applied in the direction of functional valve types, control valves, valve devices, etc., can solve problems such as difficult operation, valve stem deformation, safety accidents, etc., to improve safety performance, reduce force, and avoid deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

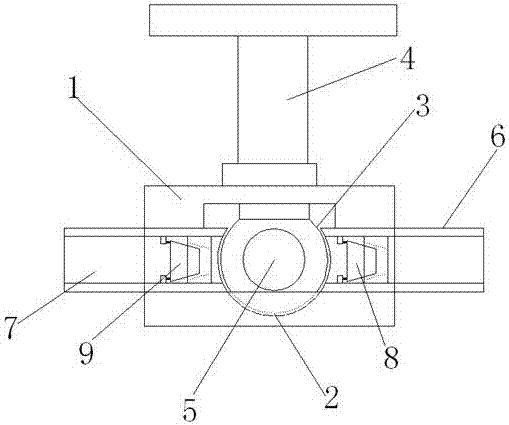

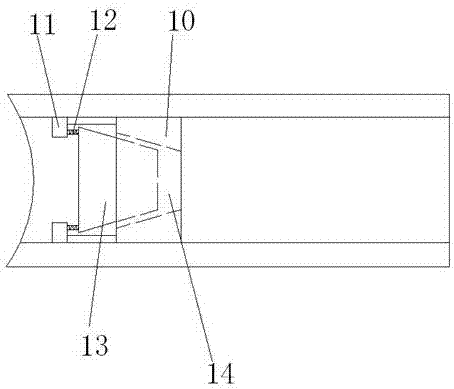

[0016] Reference Figure 1-2 , A shut-off valve with extremely high safety performance, including a hollow structure of the valve body 1, a groove 2 is opened on the bottom inner wall of the valve body 1, and the groove 2 is embedded with a steel ball 3, and one side of the steel ball 3 The outer wall is provided with a through hole 5, the top outer wall of the valve body 1 is provided with a mounting hole directly above the steel ball 3, and a valve stem 4 is installed in the mounting hole, and the bottom of the valve stem 4 is welded to the top of the steel ball 3. The outer walls on both sides of the body 1 are respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com