Simulation device and method for coupling process of sand production-mechanical parameters in hydrate-bearing sediments

A technology that contains hydrates and mechanical parameters, and is used in measurement devices, scientific instruments, particle and settlement analysis, etc. It can solve the problem of not being able to solve the coupling relationship between sand production and mechanical parameters, unable to simulate the influence law, and not considering the influence of sand production parameters. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

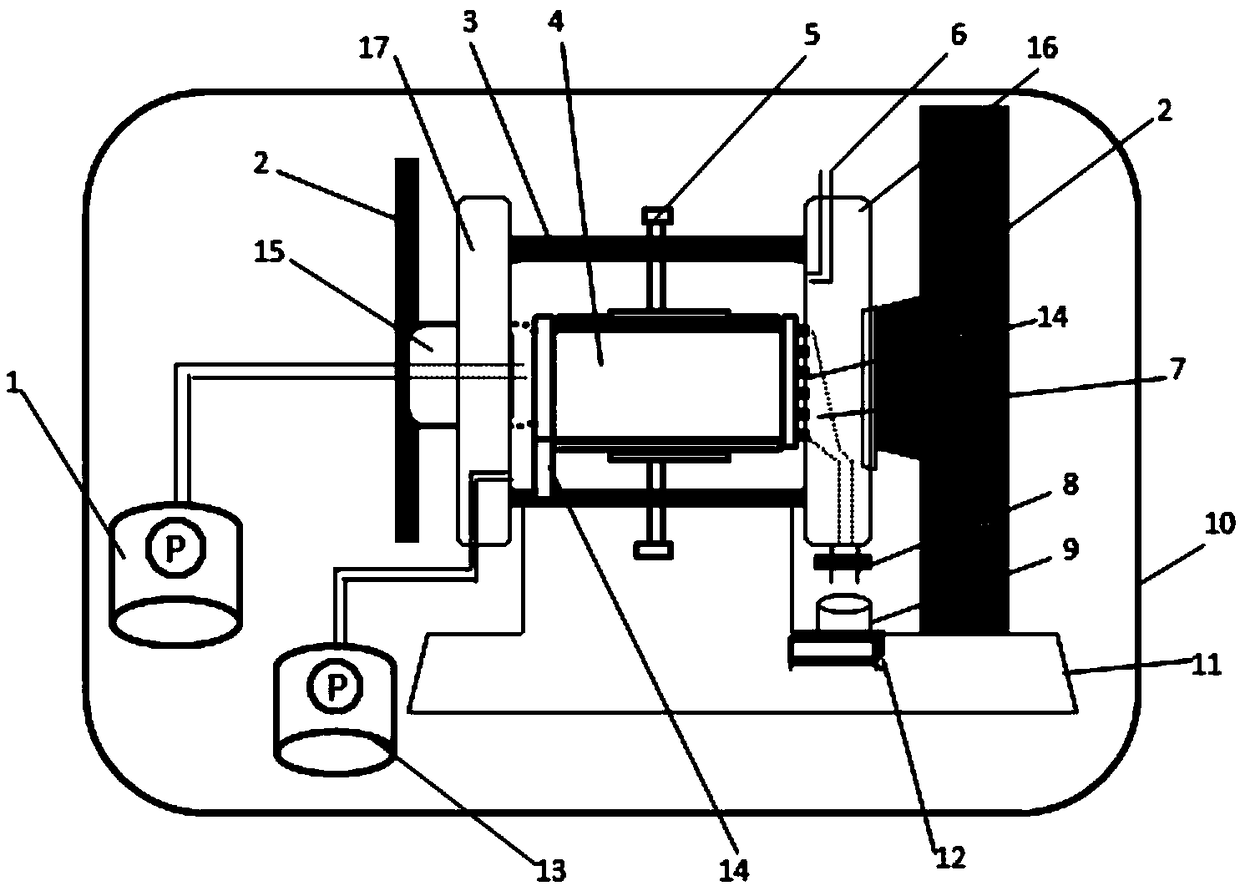

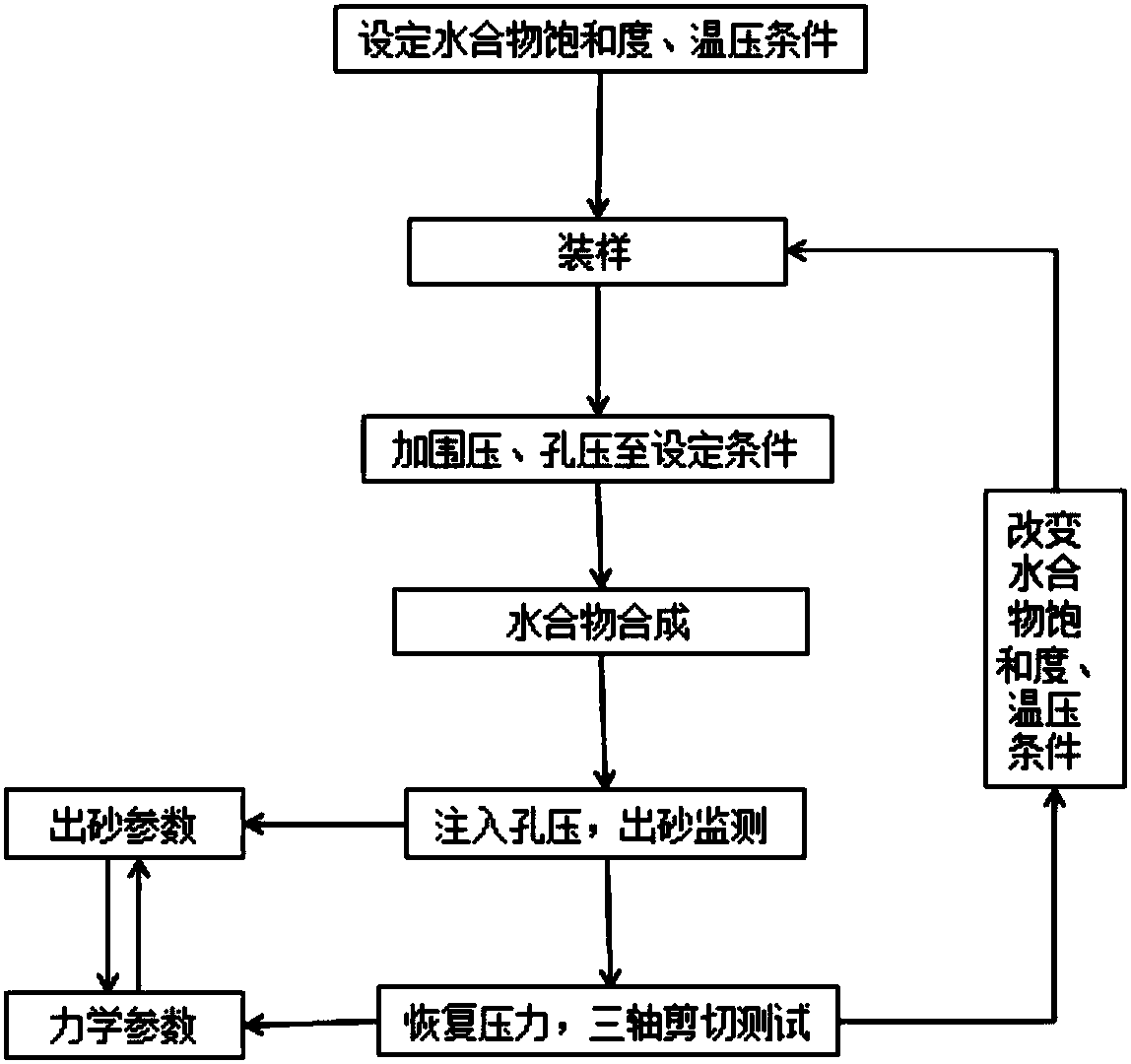

[0067] A method for simulating the sand production-mechanical parameter coupling process of hydrate-bearing sediments, comprising the following steps:

[0068] The first step, sample loading:

[0069] According to the size of the sample rubber bucket in the special reaction kettle, in the present embodiment, the size of the sample rubber bucket is Φ39.1mm×120mm, and the particle size distribution law of natural beach sand is measured, and 192g of natural beach sand is weighed. Add 16ml of distilled water, stir well and let it stand for 24 hours; then put the wet sand sample into the sample rubber barrel four times, compact it in layers, and install a porous deflector and a support flange at the inlet end of the sample rubber barrel 14. Install a perforated screen at the outlet of the sample rubber barrel.

[0070] The second step is to generate hydrate:

[0071]The confining pressure is applied to the outside of the sample rubber barrel through the confining pressure control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com