Segmentation method for brittle substrates

A brittle substrate, continuous technology, used in glass cutting devices, fine work devices, work accessories, etc., to ensure the life and reduce the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and comparative example 3

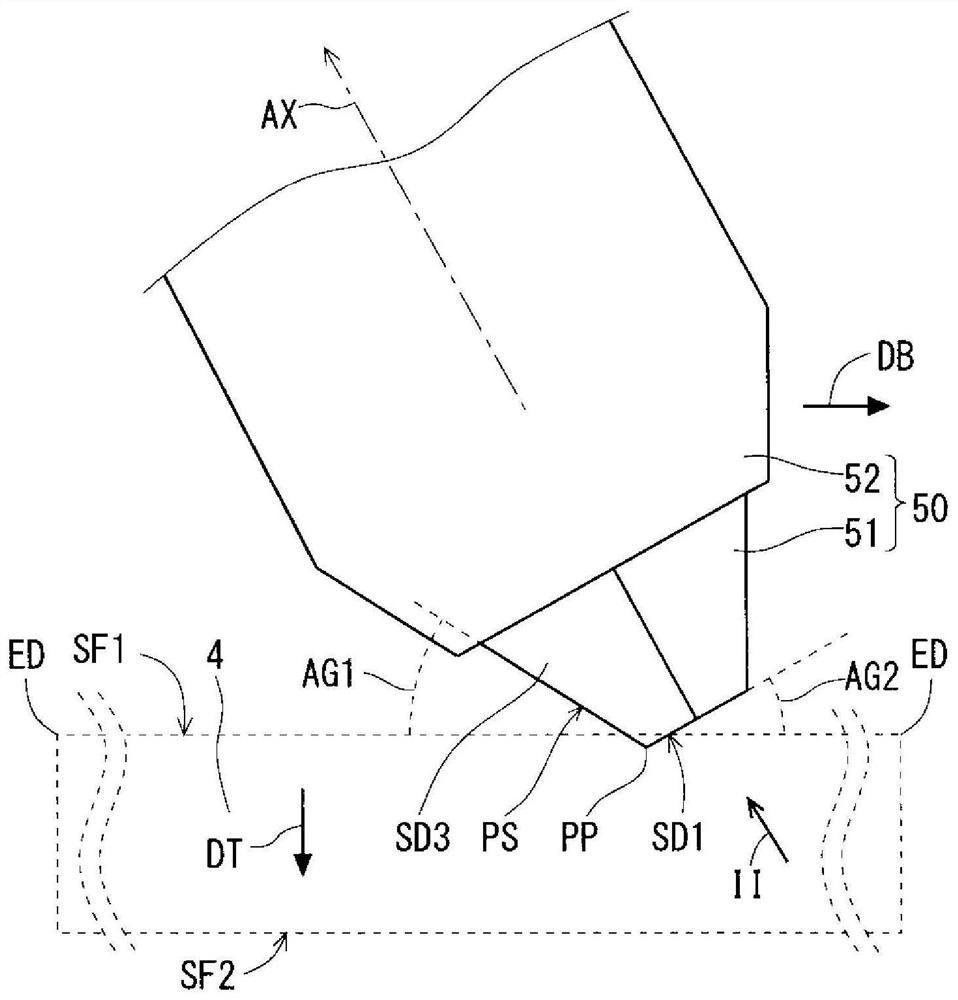

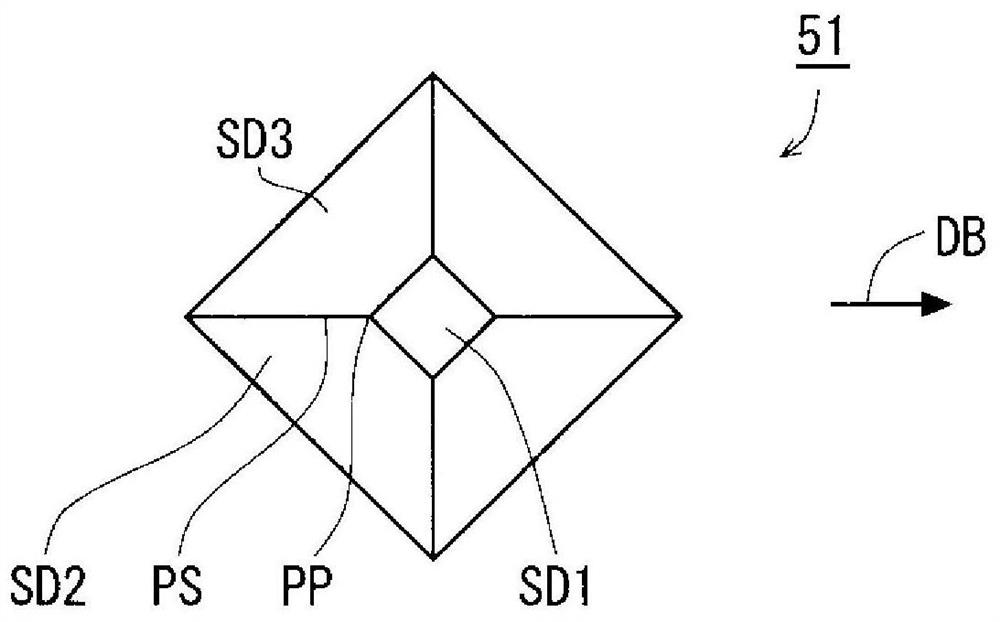

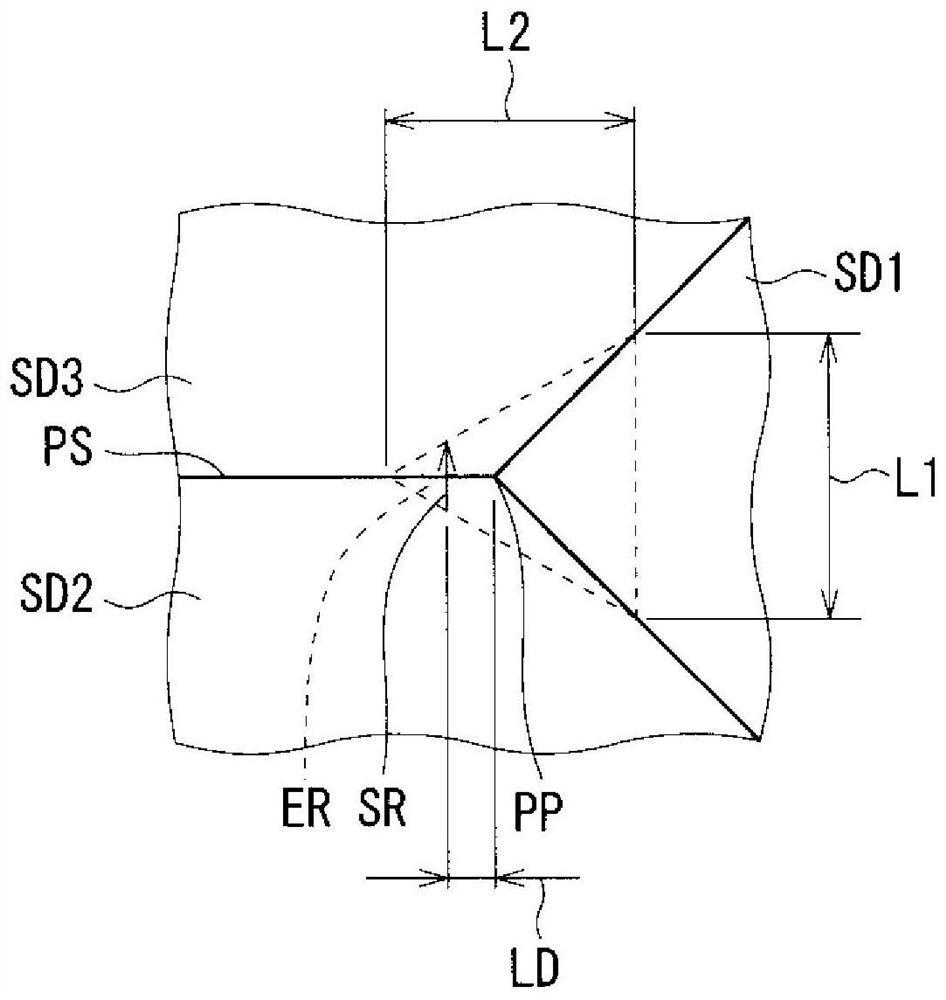

[0085] Figure 11 It is a side view which schematically shows the divided shape of the glass substrate 4 in the example of this embodiment. Figure 12 It is a side view schematically showing the divided shape of the glass substrate 4 of Comparative Example 3. FIG. The thickness of the divided glass substrate 4 was set to 0.1 mm. The surface obtained by dividing the glass substrate 4 (hereinafter also referred to as "divided surface") and Figure 11 as well as Figure 12 Corresponding to the right in , the height difference of the split planes is emphatically depicted based on the surface profile obtained by laser microscopy. The edge line PS ( image 3 ) is a ridge line without chamfering in the example, and a chamfered line in Comparative Example 3. The radius of curvature of the ridge line PS is 0.6 μm in the example, and 3.9 μm in the third comparative example.

[0086] Compared with the dividing surface of Comparative Example 3, the dividing surface of the example ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com