A self-adaptive track trolley

A rail trolley, self-adaptive technology, applied in the direction of mechanical conveyors, transportation and packaging, conveyors, etc., can solve the problem of unstable running performance of rail trolleys, and achieve the effect of solving trolley suspension stagnation and reliable small-radius turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

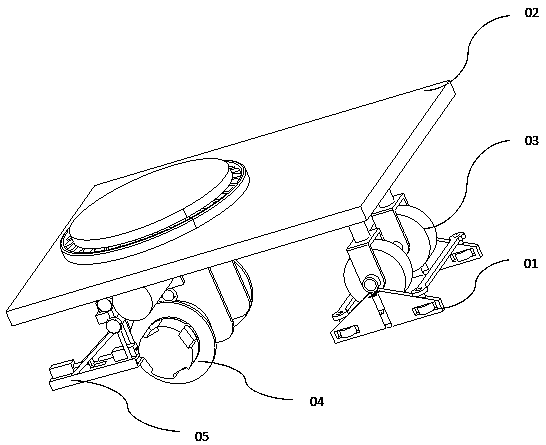

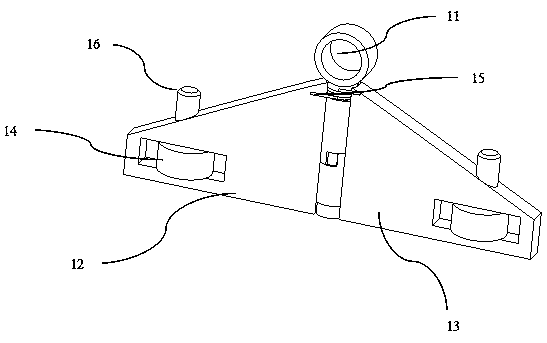

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings. as the picture shows Figure 1 to Figure 11 It is a preferred embodiment of the present invention.

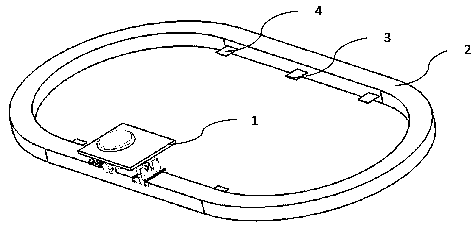

[0031] In this embodiment, the self-adaptive track trolley 1 suitable for turning with a small radius is mainly used for erecting the cross-shaped steel track 2 with a curve identification plate 3 above the breeding pond, and the curve is provided with a curve specially used for turning the trolley The limit switch 4, the trolley 1 that can walk along the track, the sensor that cooperates with the curve identification plate 3 of the culture pond is arranged on the trolley 1, the trolley sensor that cooperates with the curve limit switch 4, and whether the sensing trolley is in Front wheel sensor for walking status. like figure 1 , Shown in 2, its basic principle is: a square steel circular track 2 is erected above the breeding pond, and the track 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com