Outside-takeup double-twisting machine

A double twisting machine and wire guide technology, applied in the field of wire production, can solve the problems of limiting the capacity and quantity of the spool, difficult to achieve dynamic balance, reducing the strength of the cylinder, etc., to ensure non-stop work, light weight, The effect of enhancing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

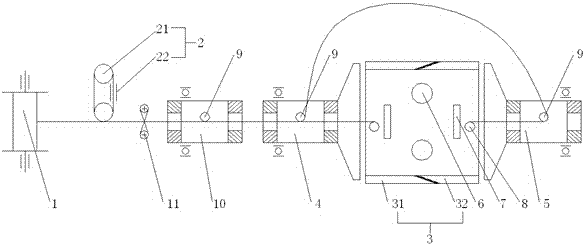

[0014] like figure 1 As shown, the present invention relates to an external take-up double-twisting machine, comprising a take-up I-shaped wheel 1, a traction wheel combination 2, a rotating body 3, a left main shaft 4 and a right main shaft 5, and left main shafts 4 are arranged on both sides of the rotating body 3 and the right main shaft 5, the rotating body 3 is provided with a pay-off I-shaped wheel 6, and the two sides of the rotating body 3 are provided with a line distribution disc 7 corresponding to the pay-off I-shaped wheel 6, between the line distribution disc 7 and the rotation body 3 A wire crimping die 8 is provided, and the crimping die 8 corresponds to the left main shaft 4 and the right main shaft 5 respectively, and the left main shaft 4 and the right main shaft 5 are equipped with a wire passing guide wheel 9, and the left main shaft 4 corresponds to the traction wheel combination 2, A third rotating main shaft 10 is arranged between the left main shaft 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com