Flaw detector

A flaw detector and detection probe technology, applied in the field of flaw detectors, can solve problems such as subjective error easily destroying bogie structure and performance, large subjective error, low bogie efficiency, etc., so as to avoid low detection efficiency, avoid subjective error problems, The effect of improving the defect detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

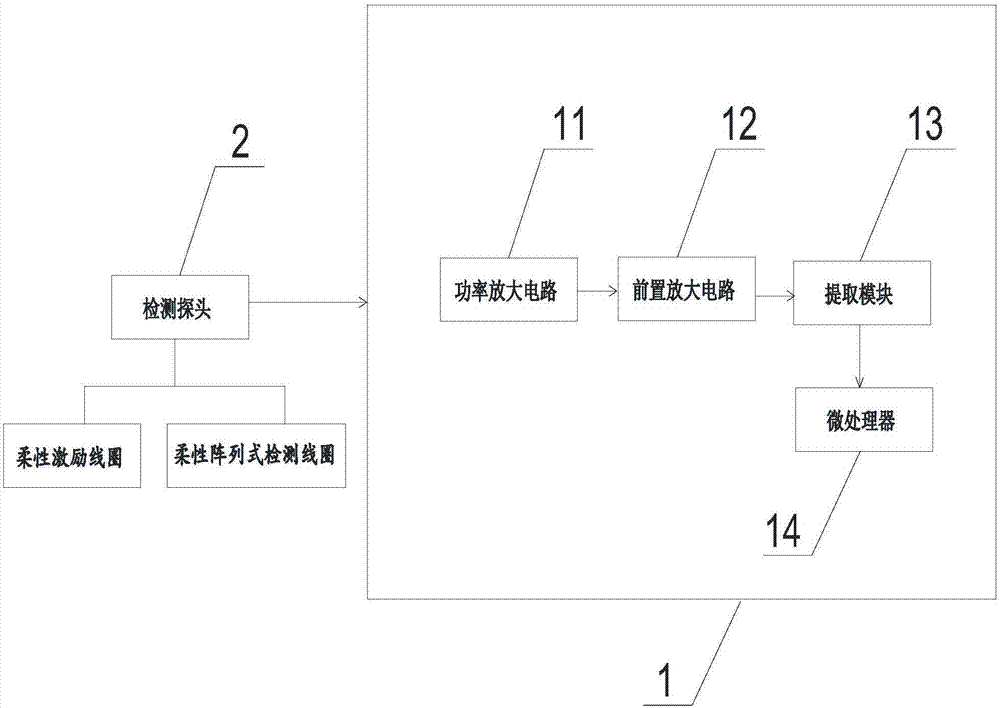

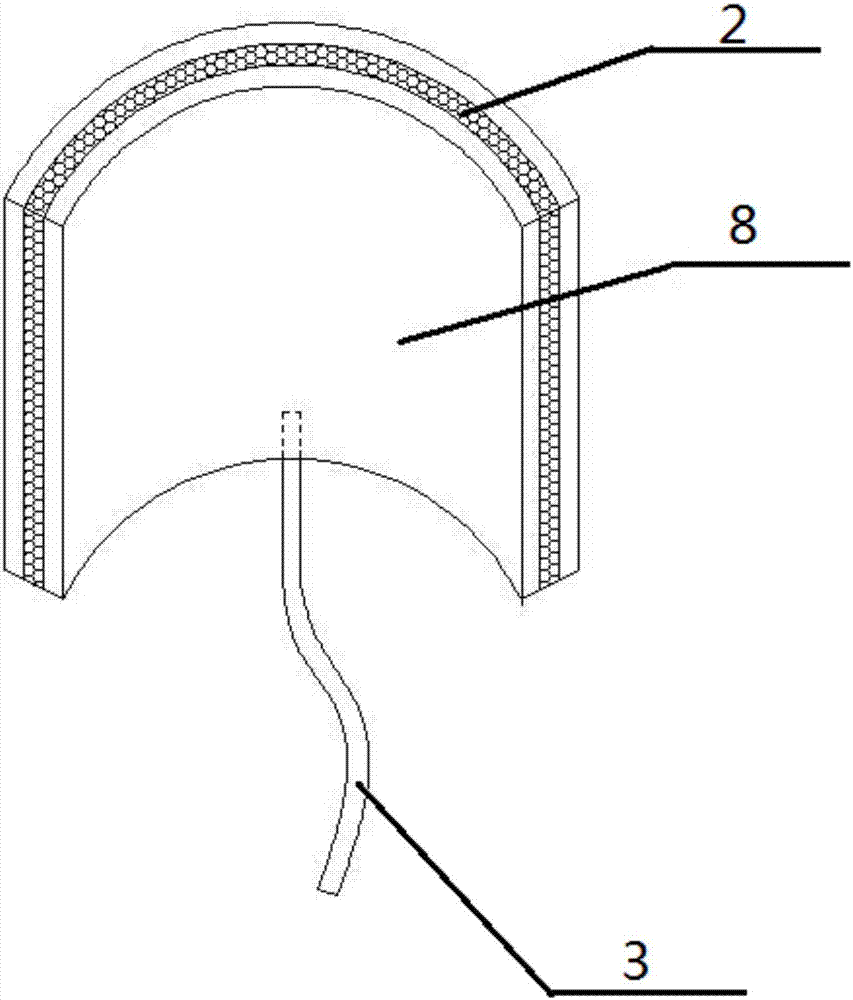

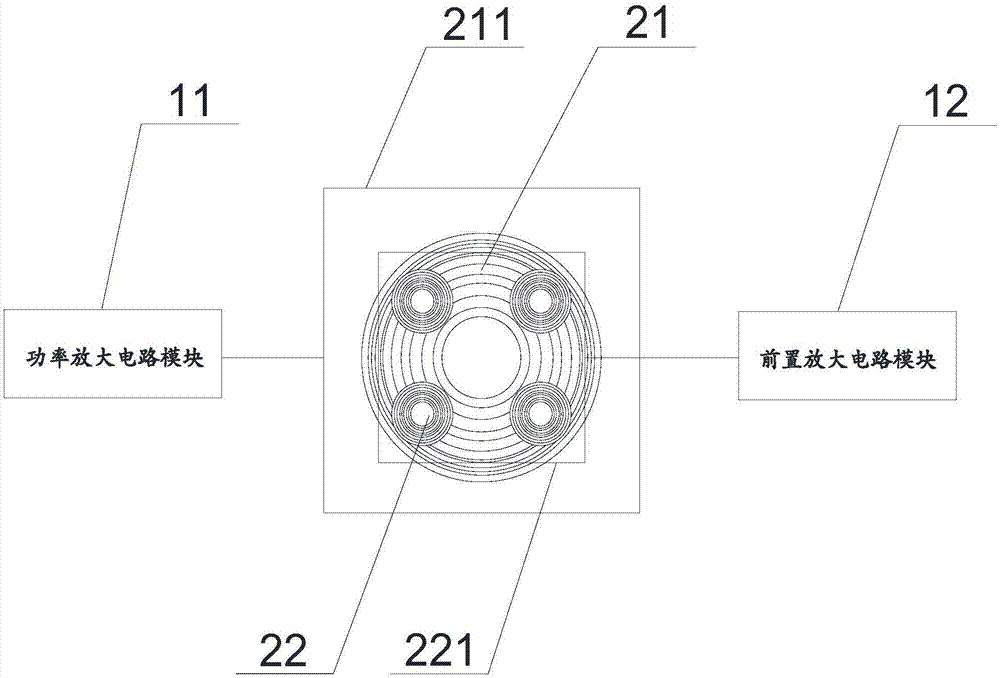

[0057]A flaw detector, comprising a controller 1 and a detection probe 2; the detection probe 2 is electrically connected to the controller 1 through a wire 3; the controller 1 includes a power amplifier circuit module 11, a preamplifier circuit module 12, an extraction module 13, and Microprocessor 14, controller 1 comprises power amplifying circuit module 11, preamplifying circuit module 12, extracting module 13, and microprocessor 14, power amplifying circuit module 11, preamplifying circuit module 12, and extracting module 13 successively Electrically connected, the output end of the extraction module 13 is electrically connected to the input interface of the microprocessor 14; the detection probe 2 includes a flexible excitation coil 21 and a flexible array detection coil 22, and the flexible ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com