Sheet punching machine

A punching machine and punching technology, applied in the field of packaging material production equipment, can solve the problems of easy scrapping of packaging materials and low punching efficiency of packaging materials, and achieve the effects of optimizing use performance, improving precision, and improving punching precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A film processor of the present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to help those skilled in the art understand the present invention, and are not intended to limit the present invention.

[0027] The film processor is mainly used for film processing of packaging materials. The packaging material should have the correct position relative to the filming device in the filming machine to improve the precision of the filming machine. The packaging material processed by the punching device should be correctly rewound, that is, the punched packaging material should have a correct position relative to the discharge wheel 12, so as to facilitate the collection of the punched packaging material.

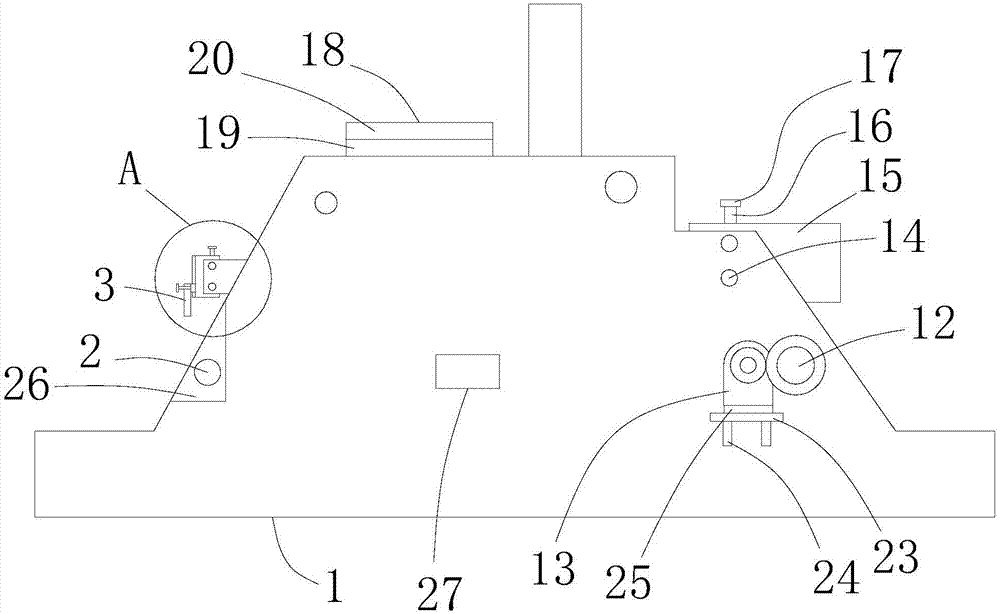

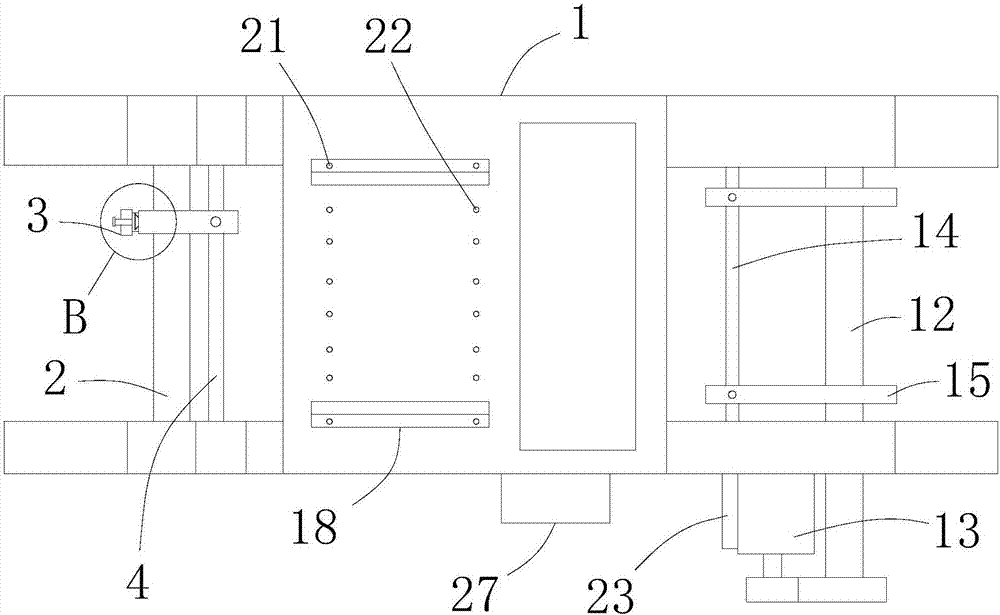

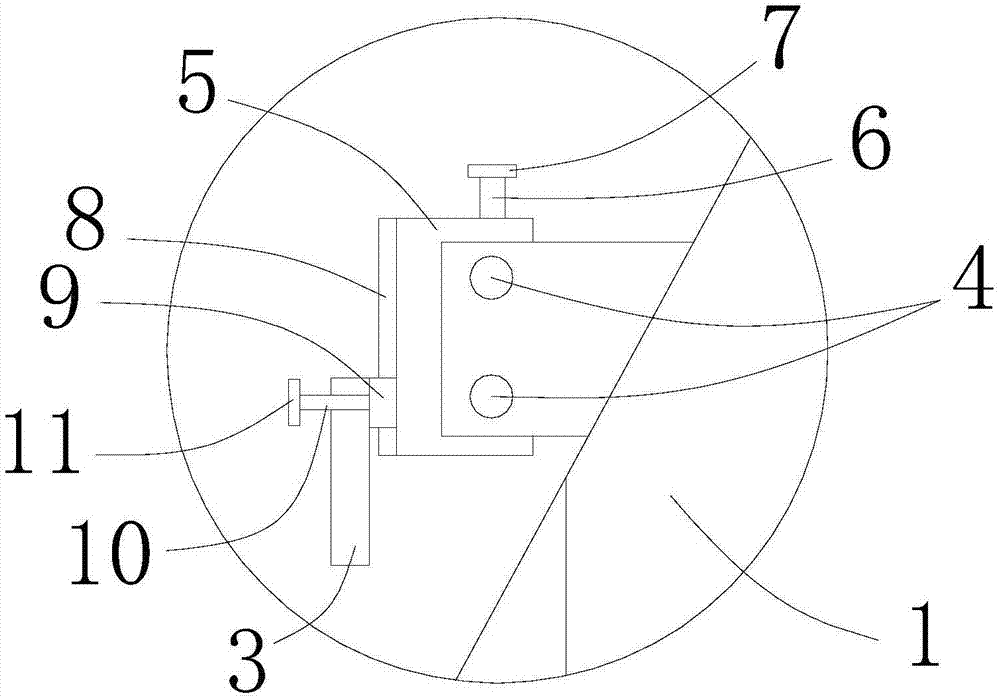

[0028] Such as figure 1 , figure 2 as shown, figure 1 is the front view of the processor, figure 2 It is a top view of the processor. Based on the above requirements, a film processor,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com