Electrical equipment moving device

A technology for mobile devices and electrical equipment, applied to motor vehicles, transportation and packaging, multi-axis trolleys, etc., can solve the problems of heavy unit modules, high labor intensity, and accidents, and achieve simple structure, reduce labor intensity, The effect of reducing the chance of personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

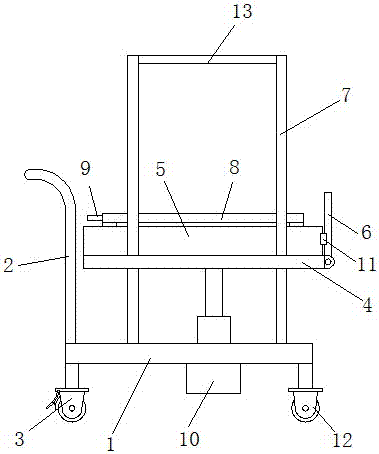

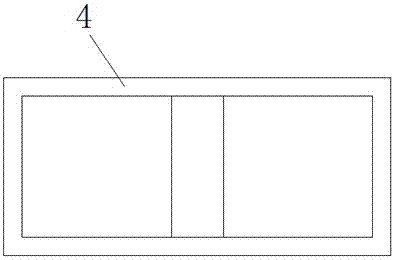

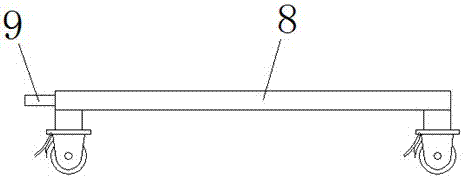

[0015] refer to Figure 1-3 , a mobile device for electrical equipment, comprising a fixed bracket 1, a push armrest 2 is fixed above one end of the fixed bracket 1, a universal belt brake caster 3 is provided below the fixed bracket 1 and one end of the push armrest 2, and the fixed bracket 1 Below and away from one end of the universal band brake caster 3 is provided with a fixed caster 12, the universal band brake caster 3 plays a fixed role to the moving device of the electrical equipment, and the rollers of the universal band brake caster 3 and the fixed caster 12 are all made of rubber Made, rubber is made and has increased the frictional force of universal ban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com