Single-curved-arc-surface tempered glass production device and method

A production device and arc surface technology, applied in glass forming, glass tempering, glass manufacturing equipment, etc., can solve the problems of severe tempering wind spots and affect optical quality, etc., to solve serious tempering wind spots and improve optical quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in combination with specific embodiments.

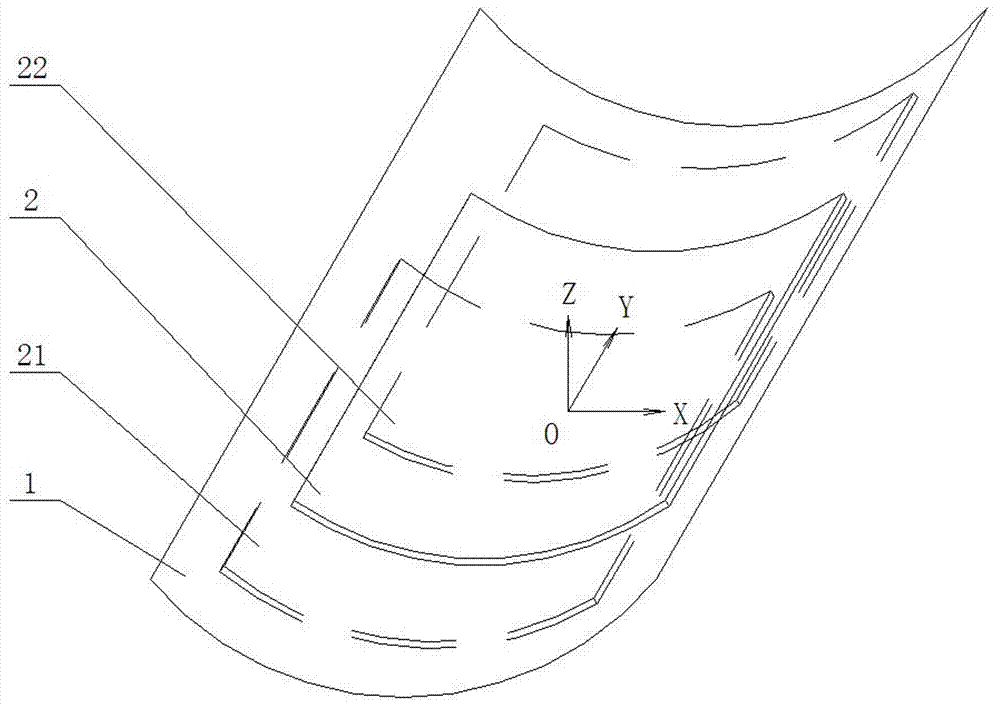

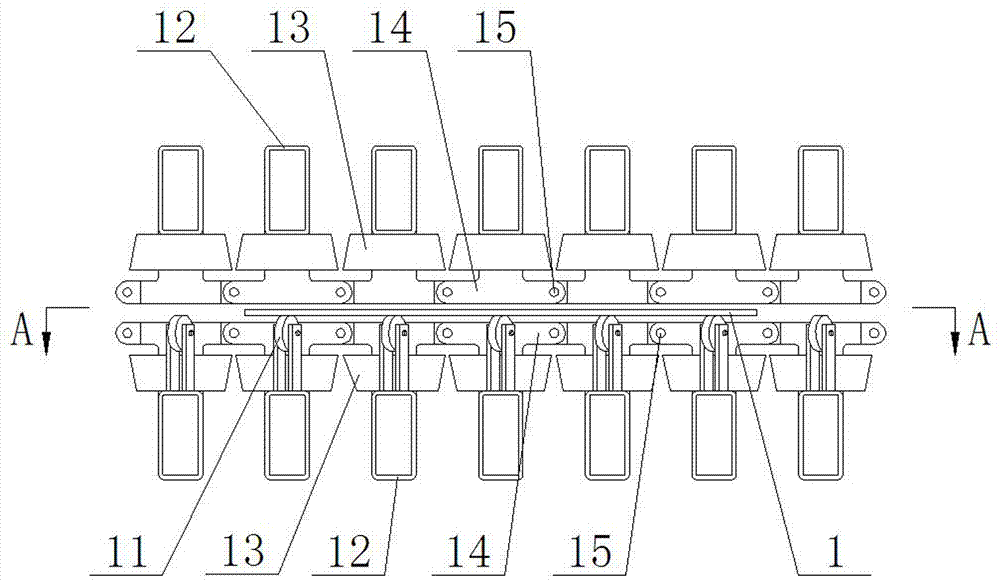

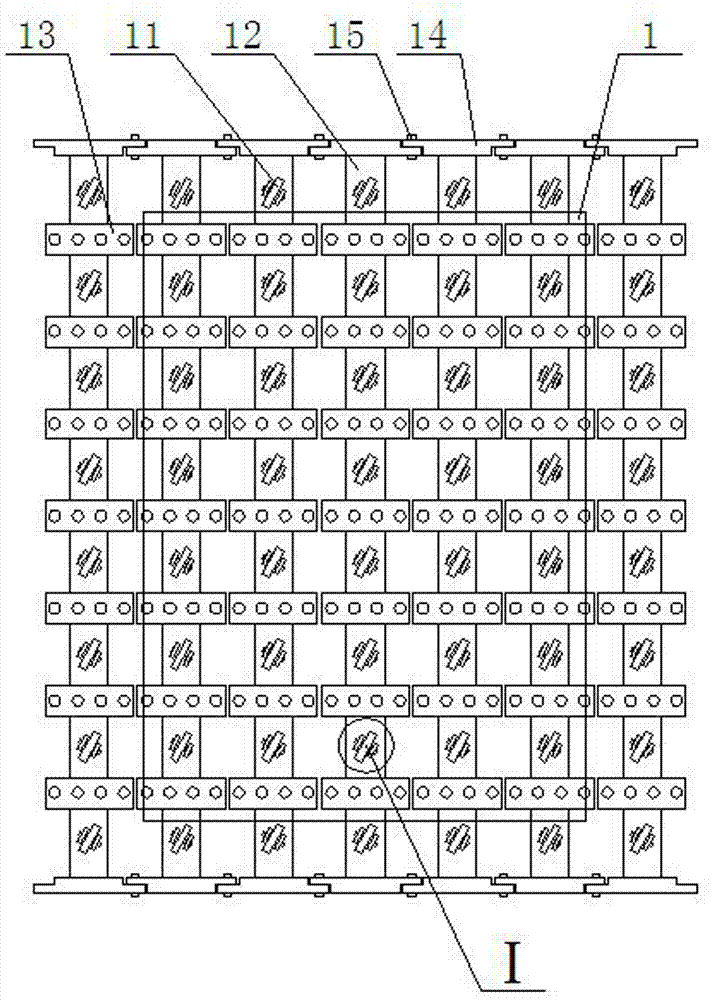

[0031] As shown in the figure: a single-curved arc surface tempered glass production device, including a heating section and a forming section, the forming section is composed of a lower part and an upper part:

[0032] The lower part of the forming section consists of multiple main beams 12 parallel to each other, multiple blowing nozzles 13, multiple forming wheels 11 and their transmission systems, and the two ends of the multiple main beams 12 are fixedly connected by hinge joint plates 14 , a plurality of forming wheels 11 and blowing nozzles 13 are installed on the main beam 12, and the forming wheels 11 and blowing nozzles 13 are installed on the main beam 12 at equal distances, and the axis of the forming wheel 11 and the axis of the installed main beam 12 form The included angles B are the same, and 0°﹤B﹤90°, the blowing nozzle 13 faces the glass 2; the surface 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com