Positioning fixture for medium and low speed maglev track J III telescopic joint installation

A magnetic levitation track and positioning tooling technology, which is applied to track, track laying, track maintenance, etc., can solve the problems of speeding up the installation progress of JⅢ expansion joints, good use effect, and inability to position the mounting seat, so as to solve the problem of inability to position and use the effect Good, high positioning accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

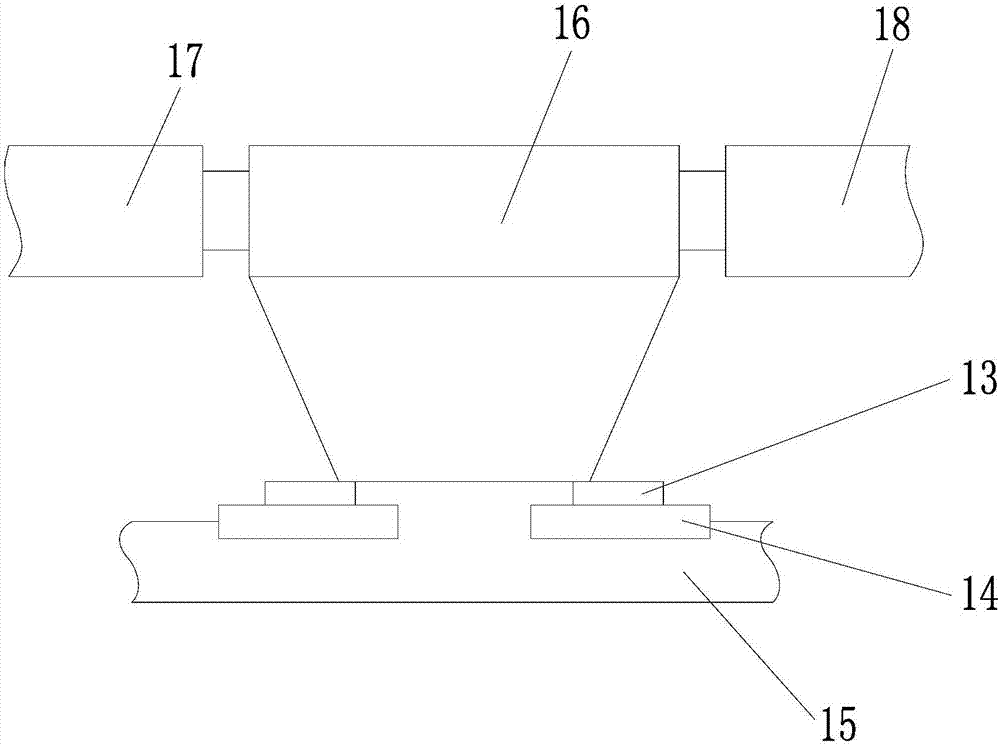

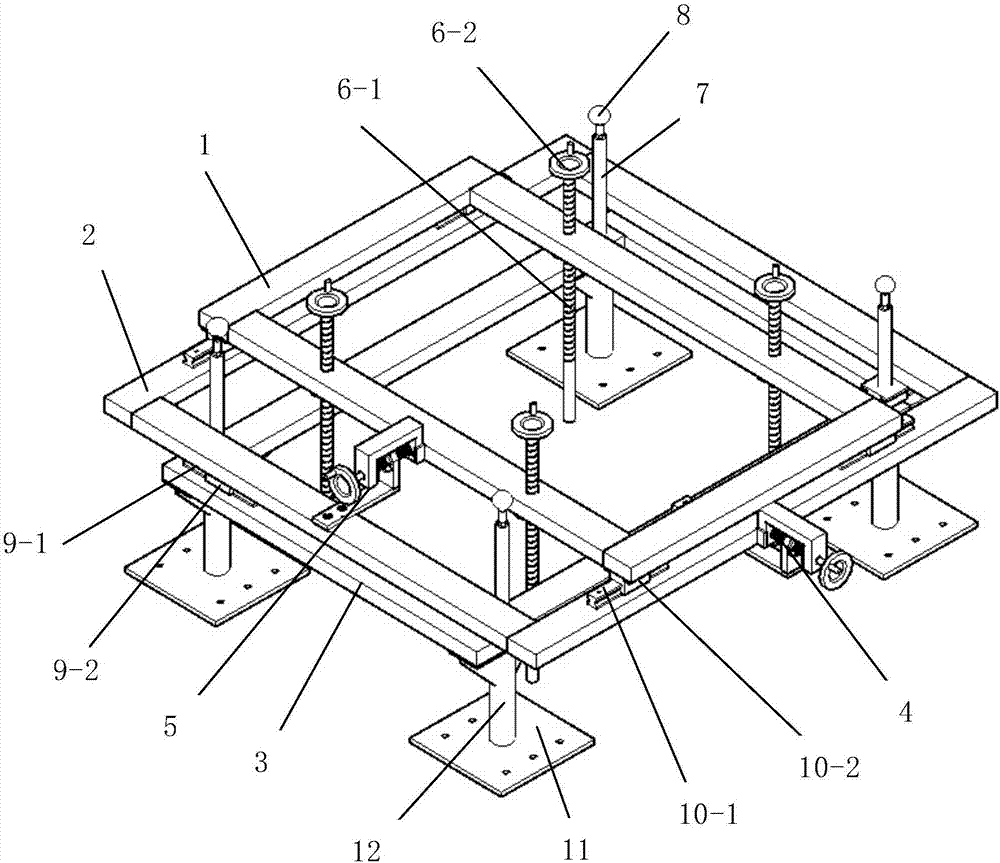

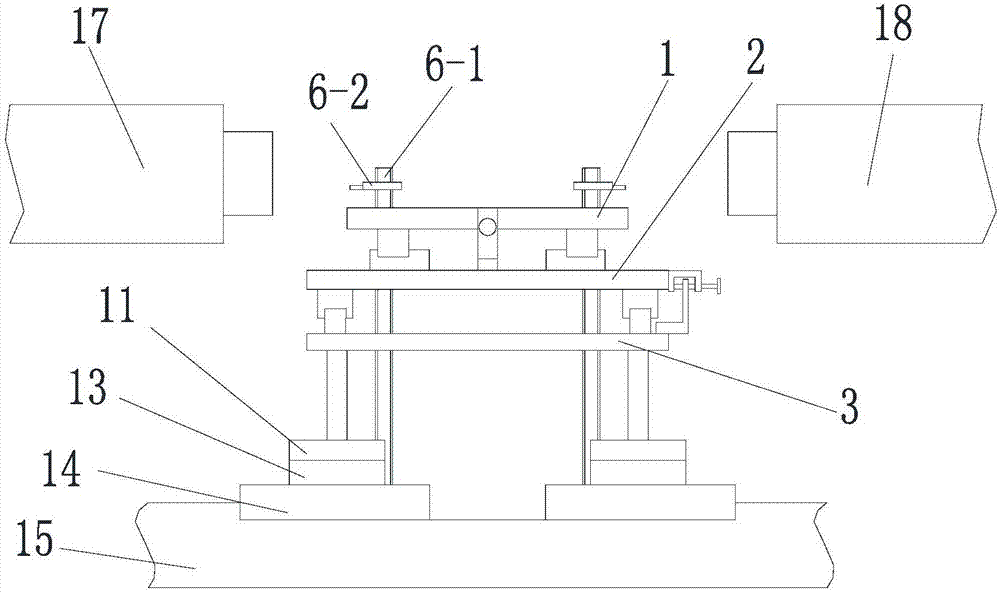

[0035] like figure 2 As shown, the present invention includes a main frame body 3, and a longitudinal adjustment mechanism, a horizontal adjustment mechanism and a height adjustment mechanism for adjusting the installation position of the JIII type telescopic joint mounting seat. The main frame body 3 is provided with a The prism 8 matched with the instrument; the lateral adjustment mechanism includes a lateral adjustment frame body 2 and a first screw moving mechanism 4 for driving the lateral adjustment frame body 2 to move laterally, and the lateral adjustment frame body 2 and the main frame body 3 are slidably matched , the first screw moving mechanism 4 is installed between the horizontal adjustment frame body 2 and the main frame body 3; the longitudinal adjustment mechanism includes a longitudinal adjustment frame body 1 and a second screw rod for driving the longitudinal adjustment frame body 1 to move longitudinally The moving mechanism 5, the longitudinal adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com