Reinforcing steel tube grouting anchor construction method applicable to retaining wall protection slope

A technology of grouting anchor rods and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of long working cycle, poor adaptability of reinforced anchor rod retaining walls, cumbersome procedures of anchor cable retaining walls, etc. problem, to achieve the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

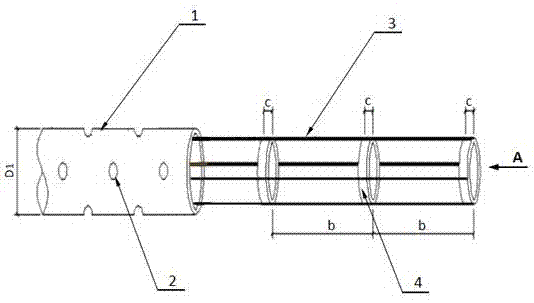

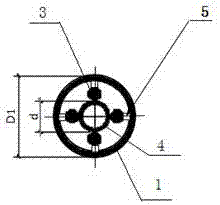

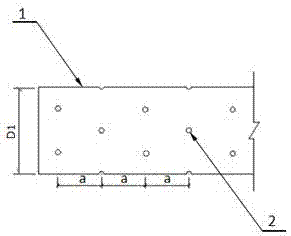

[0018] Such as figure 1 , 2 , Shown in 3 and 4, the reinforced steel pipe grouting anchor bolt construction method suitable for retaining wall slope protection once of the present invention shortens the construction period of retaining wall slope protection, and ensures that the one-time rapid construction of retaining wall slope protection under complex geological conditions form, including the following steps:

[0019] (1) According to the process design requirements, select the steel pipe segment, and open a number of slurry holes on the circumference of the steel pipe segment, and the slurry hole is connected with the inner cavity of the steel pipe segment;

[0020] (2) According to the process design requirements, make a composite steel skeleton; the composite steel skeleton includes a number of lining steel rings and reinforcing steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com