Self-suction vortex pump

A vortex pump, self-priming technology, applied in the field of self-priming vortex pumps, can solve the problems of increased labor intensity, easy noise generation, eardrum damage, etc., to reduce labor intensity, reduce pollution, and prevent eardrum damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

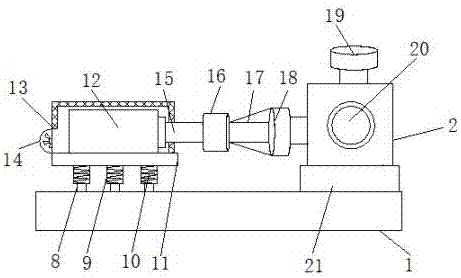

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

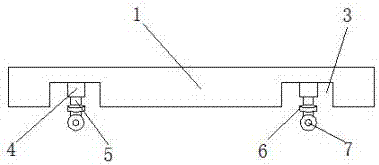

[0016] see Figure 1-2 , the present invention provides a technical solution: a self-priming vortex pump, including a fixed base 1 and a water pump 2, the left and right sides of the bottom of the fixed base 1 are provided with inner tanks 3, and the interior of the inner tank 3 is provided with There is a pneumatic cylinder 4, a pneumatic push rod 5, a bearing 6 and a moving mechanism 7. The upper left of the fixed base 1 is provided with a guide post 8, a guide post groove 9, a damping spring 10 and a damping plate 11. The damping The top of the plate 11 is fixedly connected to the water pump motor 12, the water pump motor 12 is located inside the soundproof cover 13, the soundproof cover 13 is fixedly connected to the vibration damping plate 11, and the lower left side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com