A dual-circuit cryogenic loop heat pipe working in the temperature range of 160k to 220k

A loop heat pipe, double-loop technology, applied in the field of loop heat pipe, double-circuit cryogenic loop heat pipe, can solve the problems of poor heat transfer capacity of the loop heat pipe, unable to meet the heat transfer performance requirements of the loop heat pipe, and achieve Effect of efficient heat transfer function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0025] This embodiment provides a dual-circuit cryogenic loop heat pipe adapted to the working temperature range from 160K to 220K, which can realize the start-up and operation functions across temperature ranges from the normal temperature range to the 160K low temperature range.

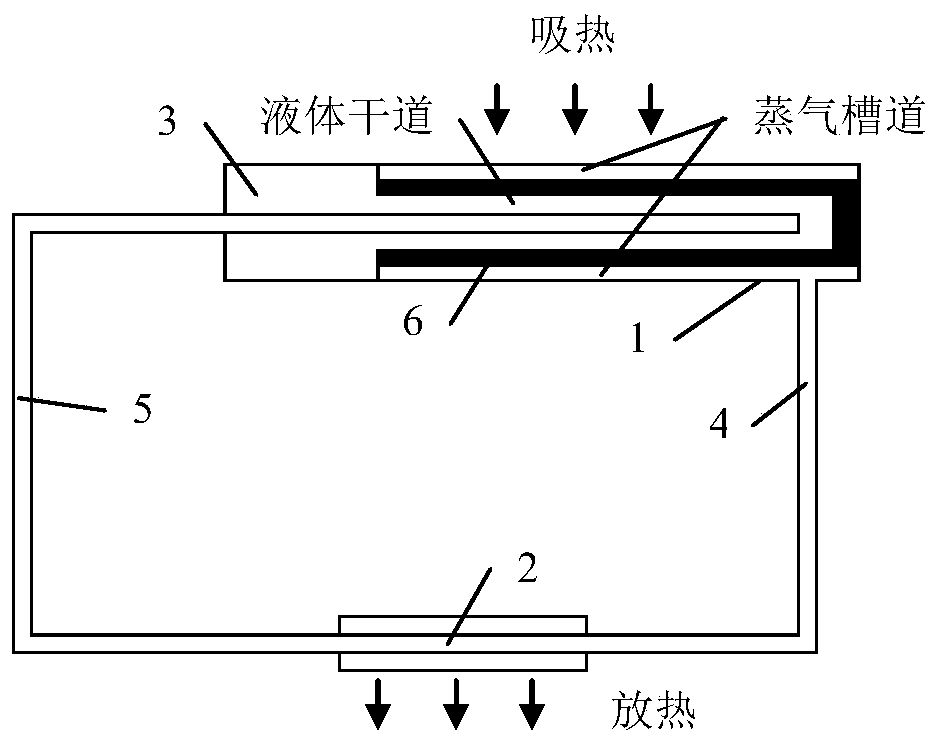

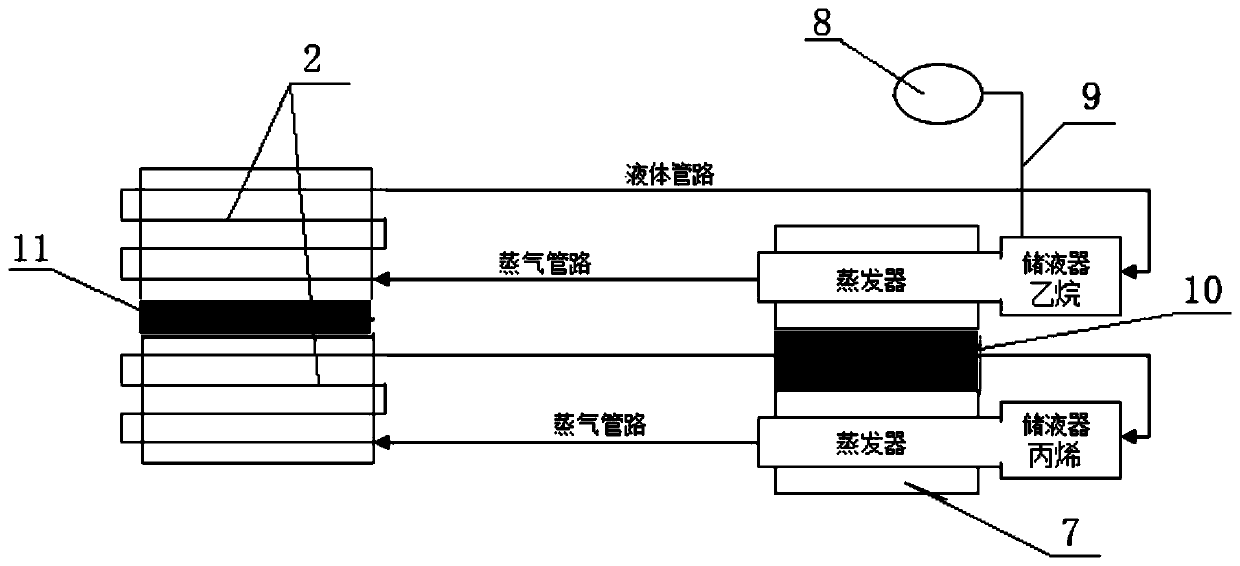

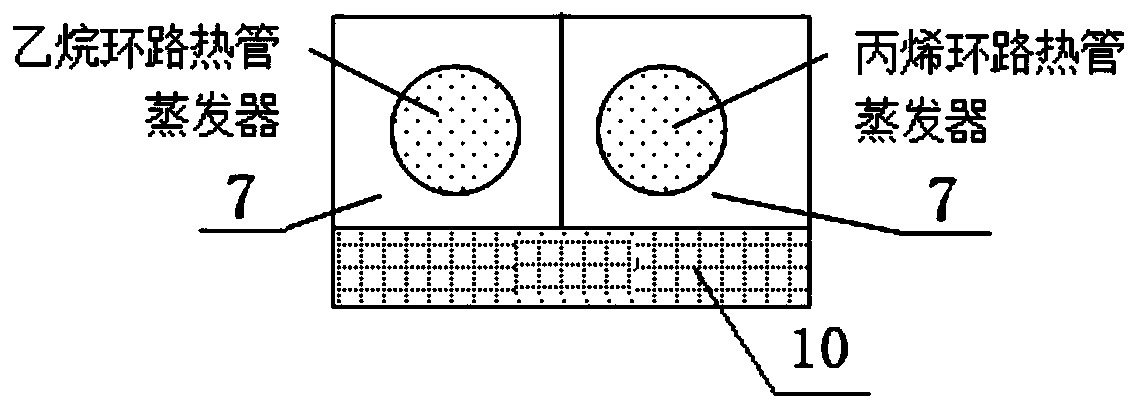

[0026] The double-circuit cryogenic loop heat pipe uses two sets of loop heat pipes that are thermally coupled together with the evaporator and condenser to solve the problem of heat transfer in the temperature range from 160K to 220K. The specific structure is as follows: figure 2 As shown, it includes: a set of loop heat pipes using ethane working fluid (ie, ethane working fluid loop heat pipe) and a set of propylene working fluid loop heat pipes (ie, propylene working fluid loop heat pipe). The evaporators of the two sets of loop heat pipes are thermally coupled together th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com