Oval-cross-section type low-wind-pressure lead

A technology with elliptical cross-section and wires, which is applied in the direction of conductors, insulated conductors, and power cables with shielding layers/conductive layers, etc., can solve the problems of limited wind resistance effect and large capital investment, so as to improve wind resistance performance and reduce Wind pressure coefficient, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

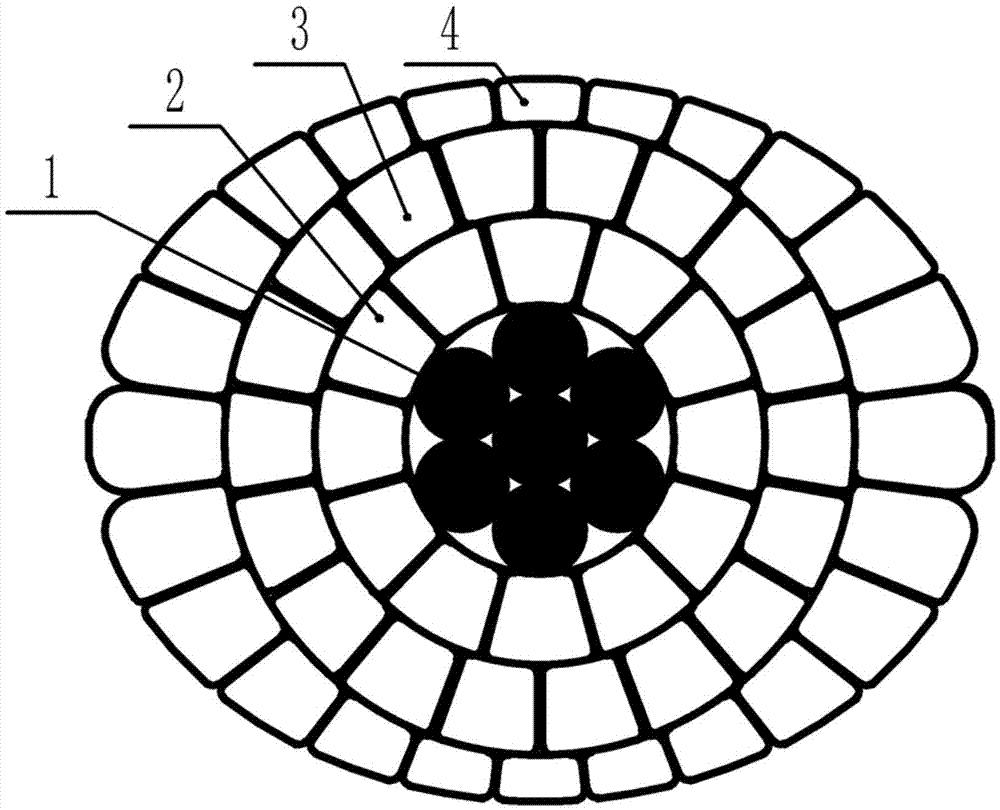

[0027] Such as figure 1 As shown, a low wind pressure conductor with an elliptical cross-section, the cross section of the conductive single wire in the outer conductor is an equiangular shaped wire structure, that is, the conductive single wire in the outer conductor is twisted according to the number of angles equal to the cross section of the conductive single wire composed of arrays.

[0028] From the inside to the outside are the reinforcing core and the 3-layer conductive single wire twisted in the outer layer. The cross section of the conductive single wire formed by twisting the conductive single wire is oval, and the conductive single wire stranded in the outer layer is the inner layer conductor, the middle layer conductor and The outer layer conductor; the conductive single line section of the outer layer conductor is an equiangular shaped line structure. The inner-layer conductor and the middle-layer conductor are formed by twisting a conductive single-wire structu...

Embodiment 2

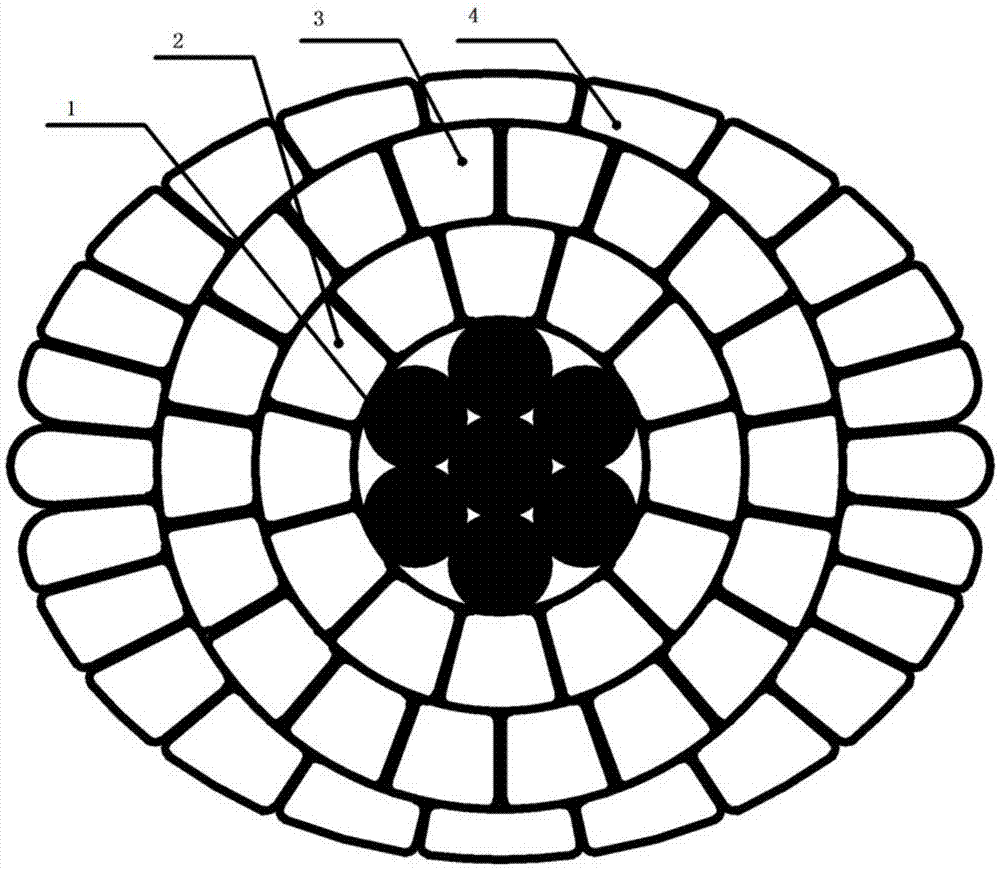

[0032] Such as figure 2 As shown, a low wind pressure wire with an elliptical cross section, the conductive single wire cross section in the outer conductor is a shaped wire structure with a constant cross section. That is to say, the conductive single wires in the outer conductor are twisted and arranged according to the equal cross-sectional area of the conductive single wires.

[0033] From the inside to the outside are the reinforcing core and the 3-layer conductive single wire twisted in the outer layer. The cross section of the conductive single wire formed by twisting the conductive single wire is oval, and the conductive single wire stranded in the outer layer is the inner layer conductor, the middle layer conductor and The outer layer conductor; the cross section of the conductive single wire of the outer layer conductor is a profiled wire structure of equal cross section. The inner-layer conductor and the middle-layer conductor are stranded conductive single wire...

Embodiment 3

[0036] The utility model relates to a low-wind-pressure wire with an elliptical cross-section. The cross-section of the conductive single wire in the outer conductor is a molded wire structure with a constant cross-section. That is to say, the conductive single wires in the outer conductor are twisted and arranged according to the equal cross-sectional area of the conductive single wires.

[0037] From the inside to the outside are the reinforcing core and the 4-layer conductive single wire twisted in the outer layer. The cross section of the conductive single wire formed by twisting the conductive single wire is oval, and the conductive single wire stranded in the outer layer is the inner layer conductor, the middle layer conductor and The outer layer conductor; the cross section of the conductive single wire of the outer layer conductor is a profiled wire structure of equal cross section. The inner-layer conductor and the middle-layer conductor are formed by twisting a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com