Pulsating heat pipe active thermal protection structure coupled with ablative resistant materials

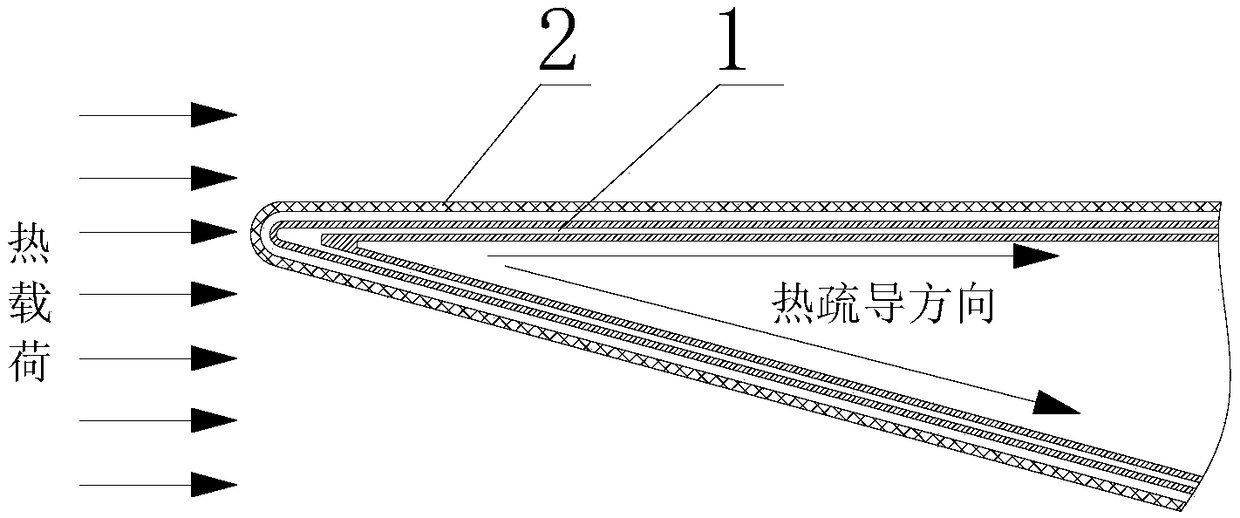

A technology of thermal protection structure and pulsating heat pipe, which is applied in the directions of aerospace vehicle heat protection device, aerospace safety/emergency device, etc., can solve the design requirements that restrict the lightweight of aircraft, the difficulty of precise control of aerodynamic aircraft, and reduce the heat protection structure. Design quality-efficiency ratio and other issues to solve the problem of material failure, avoid extreme temperature distribution, and achieve small changes in aerodynamic shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

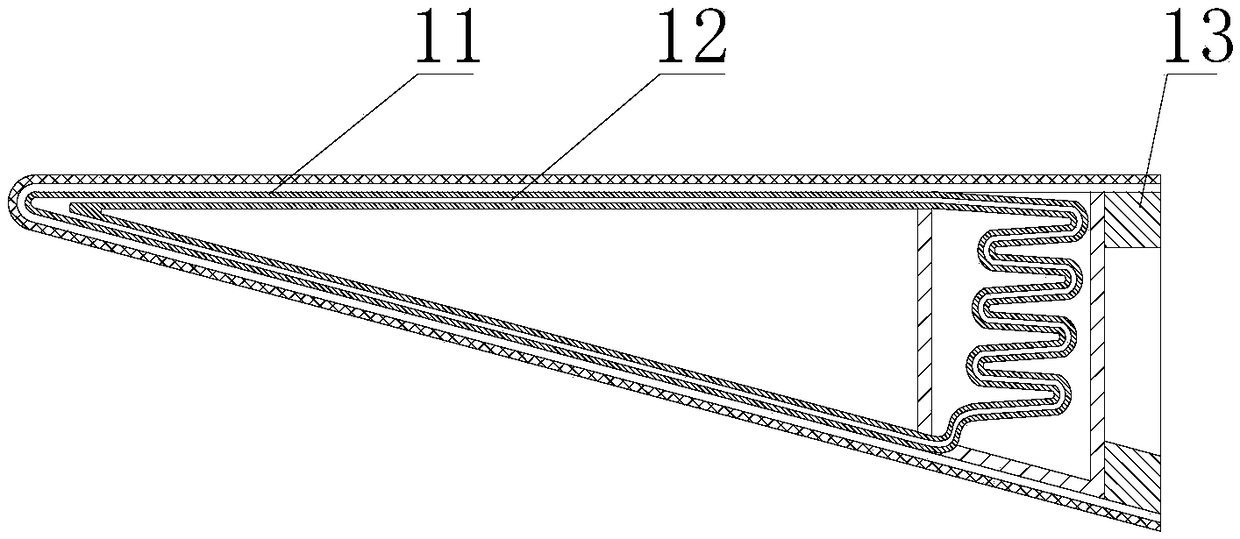

[0043] A similar geometric model of a typical hypersonic vehicle is selected, and typical flight conditions are selected, and numerical simulations and wind tunnel tests are carried out for local structures such as rudders and wing leading edges to obtain the distribution law of the surface thermal environment at the sharp leading edge. Based on numerical simulation and ground test results, carry out thermal protection structure design, conduct thermal and mechanical simulations in "startup" and "steady" states, and specifically give ablation-resistant materials heat resistance performance and structural dimensions, and pulsating heat pipe working fluid Based on the characteristics and pipeline layout parameters, a pulsating heat pipe active thermal protection structure scheme coupled with ablation-resistant materials is formed.

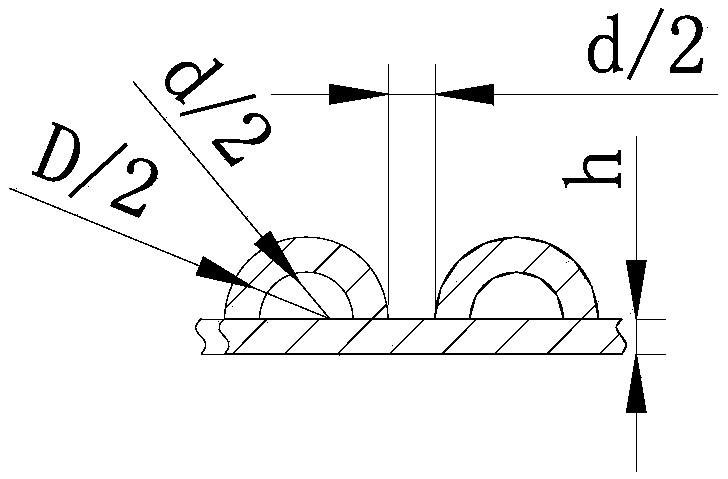

[0044] The specific design is: the thickness of the cooling panel is 1 mm, the distance between adjacent pulsating heat pipes is d / 2, and d is the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com