Method and device for coating interior of pipeline with coating

A pipeline and coating technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of inconvenient dismantling and replacement, unfavorable pipeline inner wall coating pipeline replacement, complex physical and chemical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

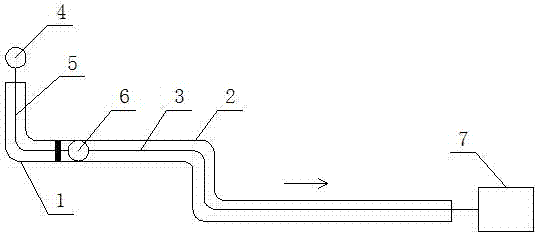

[0026] Such as figure 1 Shown, the device of the method for coating coating in a kind of pipeline of the present invention comprises coating pipeline 2, and the end of coating pipeline 2 is connected with vertical feeding pipe section 1, and the pipe diameter of feeding pipe section 1 is greater than or equal to coating The diameter of the pipe 2 is convenient for the connection between the feeding pipe section 1 and the coating pipe 2; the coating pipe 2 is built with a flow-blocking elastic hair ball 6, and one end of the flow-blocking elastic hair ball 6 is connected to the end of the soft drive shaft 3, the soft drive shaft The tail end of 3 is connected to the output end of the soft connection shaft driving device 7, and the soft connection shaft driving device 7 can provide the linear speed of forward and backward for the soft driving shaft 3, and can also provide the rotation speed at the same time, and then drive the brushing elastic hair ball 4 and the flow-blocking e...

Embodiment 2

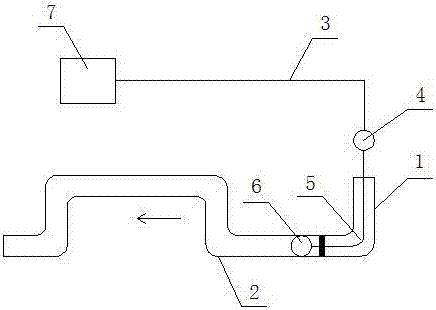

[0028] Such as figure 2 Shown, the device of the method for coating coating in a kind of pipeline of the present invention comprises coating pipeline 2, and the end of coating pipeline 2 is connected with vertical feeding pipe section 1, and the pipe diameter of feeding pipe section 1 is greater than or equal to coating The diameter of the pipe 2 is convenient for the connection between the feeding pipe section 1 and the coating pipe 2; the coating pipe 2 has a built-in flow-blocking elastic hair ball 6, and one end of the flow-blocking elastic hair ball 6 is connected to the end of the soft connection shaft 5 and the soft connection shaft The tail end of 5 is connected with the brushing elastic hair ball 4, and the other end of the brushing elastic hair ball 4 is connected with the soft driving shaft 3, and the tail end of the soft driving shaft 3 is connected with the output end of the soft connection shaft drive device 7, and the brushing elastic The hair ball 4 is located...

Embodiment 3

[0030] Such as figure 1 Shown, the method for coating coating in pipeline of the present invention, its operation method is as follows:

[0031] a. Preliminary preparation: vertically connect the feeding pipe section 1 to the coating pipe 2;

[0032] b. Assembly of the applicator: connect the end of the soft drive shaft 3 to the flow-blocking elastic hair ball 6, then connect a section of the soft connection shaft 5, and connect the front end of the soft connection shaft 5 to the brushing elastic hair ball 4;

[0033] c. Paint filling: put the brushing elastic hair ball 4 and the flow-blocking elastic hair ball 6 into the coating pipe 2 in sequence until the brushing elastic hair ball 4 exposes the port of the feeding pipe section 1 at the other end, inject paint into the feeding pipe section 1, The soft drive shaft 3 can be started and rotated to draw back the coating operation;

[0034] d. Brushing in the pipeline: Start the rotation of the soft drive shaft 3, the brushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com