Adjustment mechanism for limiting piece in leather tanning device

A technology of adjusting mechanism and limit parts, which is applied in the field of machinery, can solve problems such as poor applicability, and achieve the effect of improving structure compactness and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

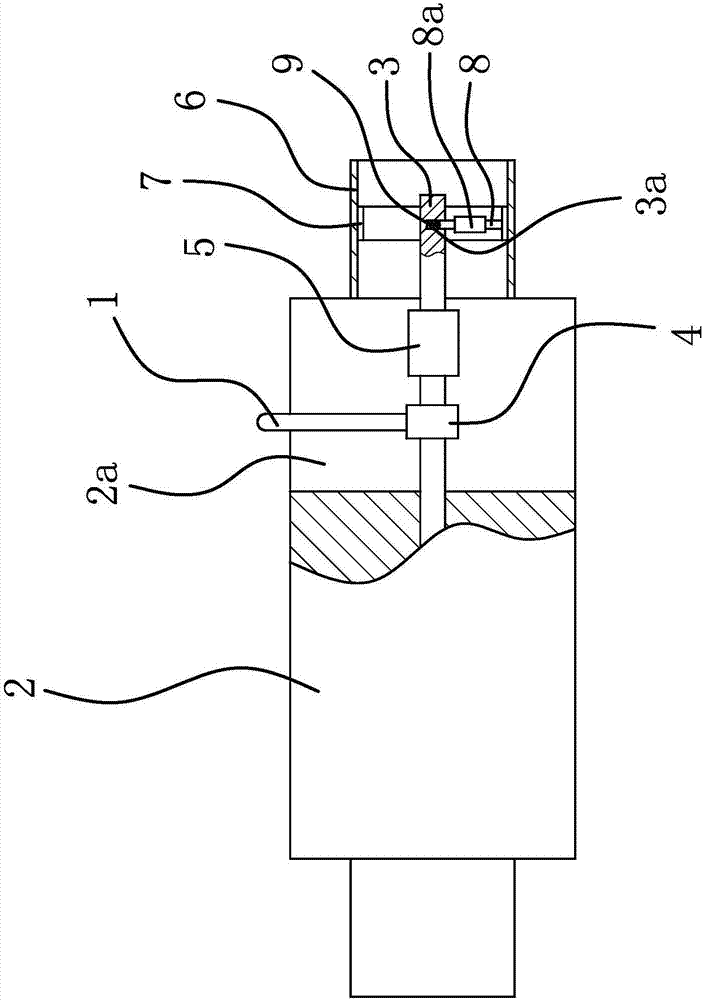

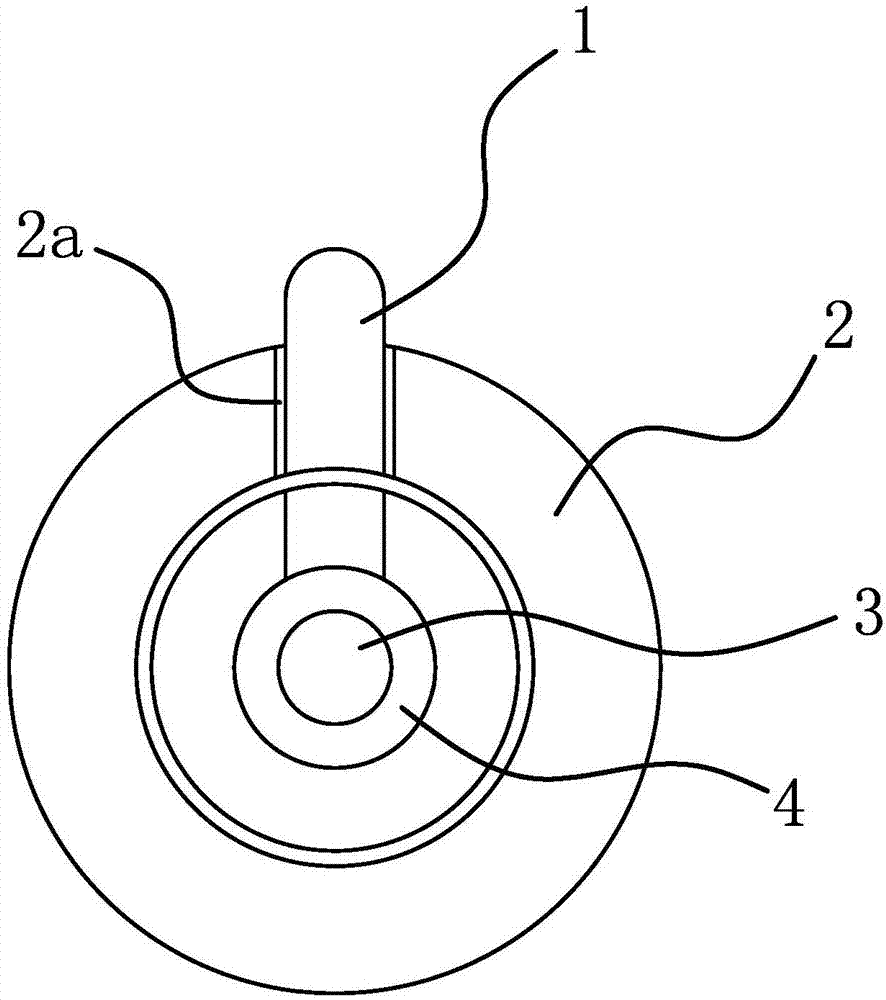

[0028] Such as figure 1 and figure 2 As shown, the lower cylinder of the leather tanning device has a stopper 1 capable of limiting leather, and the lower roller 2 has a notch 2a extending from its end to the middle, and the inner end of the stopper 1 is located at the notch 2a , the outer end of the limiting member 1 extends out of the notch 2a.

[0029] The adjustment mechanism of the stopper in the genuine leather tanning device includes a screw rod 3 and a screw sleeve 4, the above-mentioned screw sleeve 4 is fixedly connected to the lower end of the stopper 1, the above-mentioned screw rod 3 is threadedly connected with the screw sleeve 4 and the screw rod 3 stretches out from the lower cylinder.

[0030] The lower drum 2 has a cylindrical guide cylinder 5 inside, and the above-mentioned screw rod 3 is located in the guide cylinder 5 .

[0031] There are two guide cylinders 5 and the two guide cylinders 5 are fixedly connected to both ends of the lower drum 2 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com